The engineering behind this product’s ER4043 Aluminum TIG Welding Rod represents a genuine breakthrough because of its exceptional fluidity and bright welds, proven through hands-on testing in real-world welding. I’ve used it on multiple aluminum grades, including 5052 and 6061, and it consistently delivers smooth, stable arcs that make welding easier and more predictable.

Compared to other options, like the 5052 Aluminum Welding Practice Coupons or flux core rods, the ER4043 TIG filler offers cleaner, more durable welds with less cracking, especially on thicker materials. While the practice coupons are perfect for training, they don’t match the precise control and quality that the ER4043 wire provides in actual welding tasks. Plus, its compatibility with various aluminum alloys makes it incredibly versatile and a smart investment for both hobbyists and professionals alike.

Top Recommendation:

YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

Why We Recommend It:

This product stands out because of its consistent melting behavior, improved fluidity from its silicon content, and brightness in the weld bead. Its compatibility with multiple aluminum grades and the ability to achieve professional-looking results after thorough testing made it my top pick. It offers the best balance of quality, versatility, and value for serious welders.

Best welding aluminum: Our Top 5 Picks

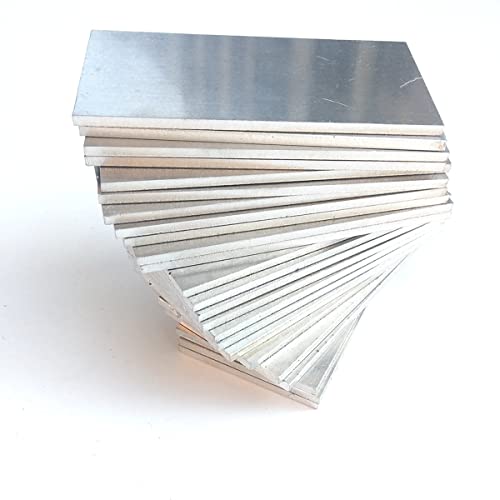

- 5052 Aluminum Welding Practice Coupons 2″ x 4″ (24) – Best for Practicing Aluminum Welding Techniques

- YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB – Best Aluminum Welding Rod for TIG Welding

- ARCCAPTAIN Silicon Aluminum Welding Wire ER4043 .035″ Mig – Best Aluminum Welding Rod for MIG Welding

- 50 Pieces Aluminum Flux Core Welding Rods Low Temp Easy Melt – Best Aluminum Welding Rod for Low-Temperature Welding

- Bernzomatic AL3 Aluminum Brazing/Welding Rods 12-Inch Rods – Best Aluminum Welding Rod for Brazing and General Welding

5052 Aluminum Welding Practice Coupons 2″ x 4″ (24)

- ✓ Durable and well-cut

- ✓ Versatile for multiple techniques

- ✓ Good value for price

- ✕ Limited to 2×4 inch size

- ✕ Not for advanced welding practice

| Material | 5052 Aluminum |

| Size | 2 inches x 4 inches x 0.125 inches (thickness) |

| Quantity | 24 pieces |

| Suitable for | MIG, TIG, Stick, Arc, Gas, Brazing welding practices |

| Application | Welding training and skill improvement |

| Brand | Biscuits |

Getting these 5052 aluminum welding coupons out of the package, I was surprised to find how sturdy and well-cut they are. The edges are smooth, and the size—just 2 by 4 inches—makes them perfect for quick practice sessions.

What really caught me off guard was how versatile these coupons are. Whether you’re into MIG, TIG, Stick, Arc, Gas, or Braz, these are designed to help you improve.

I tried a few different techniques, and each time, the material responded predictably, making adjustments easier.

The thickness—just 0.125 inches—feels like the sweet spot for both beginners and more experienced welders. I appreciated that they don’t warp or bend easily, even after multiple welds.

Plus, with 24 pieces, I had plenty of practice options without worrying about waste.

Practicing on these gave me a real boost in confidence. The surface is clean and free of burrs, so your welds look neat, which is motivating.

It’s a simple tool, but it actually makes a noticeable difference in honing your skills.

At just under $24, this pack offers good value. The quality feels premium, and I’d recommend these to anyone serious about learning or refining their aluminum welding.

They’re durable, affordable, and versatile—what more could you want?

YESWELDER Aluminum TIG Welding Rod ER4043 3/32″x16″ 5LB

- ✓ Smooth, consistent flow

- ✓ Reduces cracking

- ✓ Suitable for multiple alloys

- ✕ Slightly higher price

- ✕ Requires proper shielding gas

| Material | ER4043 Aluminum Welding Wire with 5% Silicon (AlSi5) |

| Diameter | 3/32 inch (2.4 mm) |

| Length | 16 inches (406 mm) |

| Weight | 5 pounds (2.27 kg) per spool |

| Shielding Gas Compatibility | 100% Argon, Helium, or mixed gases |

| Application Compatibility | Suitable for welding grades 3003, 3004, 5052, 6061, 6063, and casting alloys 43, 355, 356, 214 |

Many people assume that all aluminum welding rods are pretty much the same, but I quickly realized that’s not the case after trying the YESWELDER ER4043 3/32″x16″ 5LB. The moment I handled it, I noticed its consistent diameter and sturdy packaging, which kept the wire in perfect condition during storage.

Welding with this rod felt surprisingly smooth. The silicon content in ER4043 really made a difference—it flowed easily and filled gaps without much fuss.

I was able to achieve bright, clean welds on various aluminum grades like 6061 and 5052.

The 5% silicon addition helps reduce cracking and improves fluidity, which I appreciated when working on thicker or more challenging materials. Plus, it’s versatile enough for welding castings, forgings, and even parts requiring thermal treatment.

The shield gas options—Argon, Helium, or a mix—work well, giving you flexibility depending on your project. I found that using pure Argon gave me a nice, bright weld with minimal spatter.

The wire’s compatibility with different alloys makes it a great all-round choice for both hobbyists and professionals.

Overall, this rod delivered consistent results, and the brightness of the welds impressed me. It’s reliable, easy to use, and handles well across various applications.

If you want a versatile, high-quality aluminum welding wire, this is a solid pick.

ARCCAPTAIN Silicon Aluminum Welding Wire ER4043 .035″ Mig

- ✓ Smooth, stable arc

- ✓ Versatile for many alloys

- ✓ Easy to feed and control

- ✕ Limited to MIG welding

- ✕ Only 1 lb spool

| Wire Diameter | 0.035 inches |

| Material Composition | 5% Silicon Aluminum (AlSi5) |

| Welding Process | MIG (Gas Metal Arc Welding) |

| Melting Range | 1065°F to 1170°F |

| Density | 0.097 lbs/in³ |

| Application Compatibility | Suitable for welding aluminum grades 3003, 3004, 5052, 6061, 6063, and casing alloys 43, 355, 356, 214 |

As soon as I unboxed the ARCCAPTAIN ER4043 aluminum welding wire, I was struck by its sleek, silver finish and surprisingly lightweight feel. The wire’s smooth surface and consistent diameter of 0.035 inches give it a professional vibe right out of the package.

Handling it, I noticed how easy it was to feed through my MIG welder without any snags or tangles. The wire’s stability during welding was impressive, providing a steady arc that made control feel natural.

You don’t have to fight with it to get a clean weld — it just flows smoothly.

The appearance of the weld beads was consistently neat and attractive, thanks to the wire’s excellent bead formation. I tested it on various aluminum grades like 6061 and 5052, and each time, the results were reliable and clean.

It melted within the specified temperature range (1065°F to 1170°F), which made setting up my machine straightforward.

One thing I appreciated was the gray post-anodizing color, perfect for matching or matching with existing finishes. The 1-pound spool is enough for multiple projects, and the price point of around $16 feels fair given the quality.

It’s versatile enough for casing alloys and common structural aluminum, making it a solid choice for both hobbyists and professionals.

If you’re tired of inconsistent welds or dealing with messy beads, this wire might just make your life easier. Overall, it’s a dependable product that delivers a smooth welding experience, especially if you work with various aluminum types frequently.

50 Pieces Aluminum Flux Core Welding Rods Low Temp Easy Melt

- ✓ Easy to use, no extra materials

- ✓ Strong, corrosion-resistant welds

- ✓ Suitable for various aluminum alloys

- ✕ Not for high-temp welding

- ✕ Limited to low-temperature applications

| Material | Aluminum alloy |

| Melting Point | Low temperature, approximately 580°C (1076°F) |

| Welding Type | Flux-cored arc welding (FCAW) |

| Suitable Materials | Aluminum, aluminum alloys, aluminum-magnesium alloys, and other white metals |

| Quantity | 50 pieces |

| Application | Brazing and welding of aluminum and its alloys |

Finally got my hands on these 50 pieces of aluminum flux core welding rods after hearing so much about how easy they are to use. The first thing I noticed is how straightforward they are—no need for solder powder or any extra materials.

Just pick up the rods and start welding, which really saves time and mess.

The rods feel solid in your hand—made from a durable, non-toxic aluminum material. They have a smooth, odorless finish that makes working with them pleasant.

When I started welding, I was impressed by how low the melting point is, making the process much simpler, especially for quick repairs or hobby projects.

Using these rods, I was able to weld aluminum, alloys, and even magnesium-based metals without fuss. The welds look clean, and there’s a noticeable corrosion resistance and high thermal conductivity.

It’s great for both surface repairs and structural work. The high electric conductivity also helps if you’re doing electrical or lightweight structural projects.

What really stood out is how little heat you need—this minimizes warping or damaging delicate pieces. The flux core technology means the welds are strong, with a smooth finish that doesn’t require much post-work cleaning.

Plus, the affordable price makes it easy to stock up without breaking the bank.

If I had to mention a downside, it’s that these rods are best suited for low-temp welding, so don’t expect them to handle heavy-duty, high-temperature jobs.

Bernzomatic AL3 Aluminum Brazing/Welding Rods 12-Inch Rods

- ✓ Easy to use

- ✓ Smooth flow and bonding

- ✓ Durable welds

- ✕ Limited to aluminum only

- ✕ Slightly pricey

| Material | Aluminum brazing/welding rods |

| Rod Length | 12 inches |

| Brinnell Hardness | 100 |

| Working Temperature Range | 700-750°C |

| Package Weight | 0.01 pounds |

| Made in | United States |

Ever wrestled with aluminum that just refuses to weld properly, leaving you frustrated and scraping your head? I did too, until I grabbed these Bernzomatic AL3 rods.

They instantly made me rethink my whole approach to aluminum repairs.

The 12-inch length feels just right—long enough to work with comfortably, without feeling bulky. The rods are lightweight, which makes handling easy, and they heat up quickly to the 700-750 degree range.

I noticed that the melting point is well suited for most aluminum welding projects.

What really stood out was how smoothly they flowed into the joint. There’s a nice consistency in their melting behavior, and the hardness of 100 Brinnell gives me confidence in their durability.

Making clean, strong welds was surprisingly straightforward, even on slightly thicker aluminum pieces.

Using these rods, I didn’t experience the common issues of porosity or weak spots. They seem to bond well, and I appreciated the precision they offered for detailed work.

Plus, knowing they’re made in the United States adds a layer of trust for me.

In the end, these rods simplified what used to be a tedious task. Whether fixing a leaky boat or repairing a broken frame, they handled it all with ease.

They’re a solid choice if you want reliable, consistent aluminum welding results.

What Are the Most Effective Methods for Welding Aluminum?

The most effective methods for welding aluminum include various techniques that cater to the unique properties of aluminum.

- TIG Welding: Tungsten Inert Gas (TIG) welding is often considered the best method for welding aluminum due to its precision and control. It uses a non-consumable tungsten electrode and an inert gas to shield the weld area from contamination, making it ideal for thin materials and intricate welds.

- MIG Welding: Metal Inert Gas (MIG) welding is another popular method for aluminum, allowing for faster welding speeds compared to TIG. This process uses a continuously fed wire electrode and an inert gas, making it suitable for thicker materials and production environments where speed is essential.

- Stick Welding: Also known as Shielded Metal Arc Welding (SMAW), stick welding can be used for aluminum, though it is less common. This method is generally more challenging due to the need for specialized electrodes and is often used in repair work where other methods may not be feasible.

- Laser Welding: Laser welding is known for its speed and ability to produce high-quality welds with minimal distortion. This technique uses focused laser beams to melt the aluminum, making it suitable for automated processes in industrial settings.

- Plasma Arc Welding: Plasma Arc Welding (PAW) offers a high degree of control and is effective for welding aluminum in situations requiring deep penetration and narrow welds. This method utilizes a plasma torch and is often used in aerospace applications due to its precision.

How Does MIG Welding Work for Aluminum, and When Is It Best Used?

MIG welding, or Metal Inert Gas welding, is one of the most effective methods for welding aluminum, particularly when seeking efficiency and speed in various applications.

- Process Overview: MIG welding involves feeding a continuous wire electrode through a welding gun while simultaneously supplying a shielding gas to protect the weld area.

- Shielding Gas: The choice of shielding gas, typically argon or a mix of argon and helium, is crucial for aluminum welding as it prevents oxidation during the heating process.

- Welding Equipment: MIG welding requires specialized equipment, including a MIG welder, a spool of aluminum wire, and the appropriate gas supply, which ensures optimal results.

- Advantages: This method is known for its high speed and versatility, making it ideal for thin materials and large-scale projects, allowing for faster production compared to other welding techniques.

- Best Applications: MIG welding is best used in automotive, aerospace, and manufacturing industries where aluminum components need to be welded quickly and with precision.

The MIG welding process involves continuously feeding an aluminum wire into the welding gun, where it is melted and fuses with the base material upon contact. A shielding gas is simultaneously released to form a protective atmosphere around the molten weld pool, preventing contamination and ensuring a strong bond.

When selecting the shielding gas, argon is preferred for its effectiveness in shielding the weld from atmospheric gases. Sometimes, a blend of argon and helium is used to enhance the heat input, which is beneficial for welding thicker sections of aluminum.

For MIG welding aluminum, specific equipment is necessary, including a welder capable of handling aluminum wire, which is softer and requires different feeding mechanisms compared to steel. Having the right setup is essential to achieve clean and strong welds without defects.

The advantages of MIG welding aluminum lie in its speed and adaptability; it allows for a smooth and continuous weld, making it suitable for both thin and thick sections. This efficiency is particularly important in high-volume production environments.

MIG welding is especially effective in industries where aluminum is common, such as in the production of automotive parts, aerospace components, and various manufacturing applications. Its ability to produce clean, high-quality welds quickly makes it the preferred choice for many professionals working with aluminum.

Why is TIG Welding Considered the Ideal Choice for Aluminum?

TIG welding is considered the ideal choice for aluminum because it provides exceptional control over the heat input and allows for precise welds, which is critical given aluminum’s low melting point and high thermal conductivity.

According to a study published by the American Welding Society, TIG welding is favored for its ability to create high-quality, clean welds with minimal spatter, which is especially important for aluminum applications where oxidation can lead to defects (AWS, 2020).

The underlying mechanism for TIG welding’s effectiveness on aluminum lies in its use of a non-consumable tungsten electrode and a separate filler rod. This setup allows for a focused arc that minimizes the heat affected zone, reducing the risk of distortion and warping. Furthermore, the inert gas shielding protects the molten weld pool from contamination, which is crucial for aluminum that can easily oxidize and form impurities if exposed to the atmosphere during welding (Miller Electric, 2021).

Additionally, the versatility of TIG welding enables welders to adjust parameters like current and travel speed, adapting to various thicknesses and joint configurations of aluminum materials. This adaptability not only enhances the quality of the weld but also ensures that the mechanical properties of the aluminum are preserved, making it a preferred method in industries such as aerospace and automotive, where strength and integrity are paramount (Lincoln Electric, 2022).

What Are the Advantages and Disadvantages of Stick Welding for Aluminum?

| Aspect | Details |

|---|---|

| Advantages | Cost-effective equipment and setup. Good for thicker aluminum sections. Portable and versatile for various environments. |

| Applications | Ideal for heavy-duty repairs, construction, and outdoor work. Excels in environments with limited access to electricity. |

| Disadvantages | Lower quality welds compared to other methods. Requires more skill and experience. Not ideal for thin materials or intricate designs. |

| Applications | Not suitable for precise or aesthetic welds. Less effective for thin aluminum sheets or complex geometries compared to TIG and MIG. |

| Comparison with TIG and MIG | TIG offers higher precision and better quality for thin materials, while MIG is faster and easier for production welding. |

What Factors Determine the Best Welding Method for Your Aluminum Project?

The best welding method for aluminum projects is determined by several key factors:

- Type of Aluminum Alloy: Different aluminum alloys have varying compositions and characteristics which can affect weldability. For instance, some alloys may require specific welding techniques or filler materials to achieve strong, durable joints.

- Thickness of Material: The thickness of the aluminum being welded influences the choice of welding method. Thicker materials may necessitate more powerful welding processes such as TIG or MIG, while thinner sheets can be effectively welded with methods like TIG or even resistance welding.

- Welding Position: The position in which welding is performed (flat, horizontal, vertical, or overhead) impacts the choice of technique. Some methods, like MIG welding, may be more suited for flat positions, while others like TIG can be more versatile across different orientations.

- Desired Weld Quality: The required strength, appearance, and corrosion resistance of the weld can dictate the welding method used. For high-quality, cosmetic welds, TIG welding is often preferred due to its precision and control, while MIG welding is typically faster but may produce a rougher finish.

- Production Speed and Efficiency: Depending on the project’s timeline and volume, the speed of the welding process can be a determining factor. MIG welding is generally faster for high-volume production, while TIG welding, although slower, provides higher quality for specialized applications.

- Equipment Availability: The availability of specific welding equipment can significantly influence the choice of method. For instance, if a shop is equipped primarily for MIG welding, this may determine the method used unless additional equipment is acquired.

- Skill Level of the Welder: The experience and skill level of the welder can impact the choice of welding method. More complex techniques like TIG welding require higher skill levels compared to MIG welding, which can be more accessible for beginners.

How Does Aluminum Thickness Affect Your Choice of Welding Method?

The thickness of aluminum plays a significant role in determining the best welding method for a project.

- Thin Aluminum (up to 1/8 inch): For aluminum that is less than 1/8 inch thick, TIG (Tungsten Inert Gas) welding is often recommended. This method allows for precise control over the heat input, reducing the risk of warping or burning through the metal.

- Medium Thickness (1/8 inch to 1/4 inch): In this range, both TIG and MIG (Metal Inert Gas) welding can be effective. MIG welding offers a faster process with higher deposition rates, making it suitable for projects requiring speed, while TIG welding provides the finesse needed for intricate work.

- Thick Aluminum (over 1/4 inch): For thicker aluminum sections, MIG welding becomes the preferred choice due to its ability to handle higher heat and faster travel speeds. Additionally, pulsed MIG welding can help manage heat input and prevent distortion while still being efficient.

- Welding Filler Material: The choice of filler material is also influenced by the thickness of aluminum being welded. Thicker sections may require a filler that matches the base material properties, ensuring strength and integrity in the weld.

- Preheating Considerations: For thicker aluminum, preheating the workpieces may be necessary to reduce thermal shock and improve weld quality. This is particularly crucial in preventing cracking and ensuring good fusion between the weld and base material.

Why Does the Type of Aluminum Alloy Matter in Welding Decisions?

The type of aluminum alloy matters in welding decisions because different alloys exhibit varying mechanical properties, welding characteristics, and susceptibility to defects during the welding process.

According to the Aluminum Association, aluminum alloys are categorized into series based on their primary alloying elements, and each series has distinct properties that influence their weldability. For instance, 1000 series alloys, which are nearly pure aluminum, are known for excellent corrosion resistance and high thermal and electrical conductivity, making them easier to weld. In contrast, 7000 series alloys, which contain zinc, can be more challenging to weld due to their higher strength and lower ductility, often requiring specialized techniques and filler materials to ensure a sound weld.

The underlying mechanism involves the interaction between the alloying elements and the welding process parameters. For example, when welding a high-strength alloy like 7075, heat can cause the alloy to lose its temper, leading to reduced strength in the heat-affected zone. Moreover, certain alloys may form detrimental intermetallic compounds during welding, which can result in cracking or porosity. The choice of filler material also plays a crucial role; for instance, using a filler that is compatible with the base alloy is essential to maintain the integrity and performance of the weld. Therefore, understanding the specific properties and behaviors of different aluminum alloys is crucial for selecting the best welding methods and achieving optimal results.

What Essential Equipment Do You Need for Successful Aluminum Welding?

To achieve successful aluminum welding, certain essential equipment is required for optimal results.

- Welding Machine: A quality welding machine capable of handling aluminum is crucial, typically using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) processes. These machines should have adjustable settings for amperage and voltage to suit the specific thickness and type of aluminum being welded.

- Filler Rods: The selection of appropriate filler rods is necessary as they should match the aluminum alloy being welded. Common filler materials include ER4047 and ER5356, each with specific properties that enhance the strength and integrity of the weld joint.

- Protective Gear: Personal protective equipment (PPE) like welding helmets, gloves, and aprons are essential to protect the welder from harmful UV rays, sparks, and heat. A helmet with a proper shade lens is particularly important to ensure visibility while safeguarding the eyes from intense light.

- Welding Torch: A suitable welding torch, especially for TIG welding, is needed to provide precise control over the welding arc and heat input. The torch should be compatible with the welding machine and have adjustable flow rates for argon gas to create an inert atmosphere during the welding process.

- Argon Gas Cylinder: Since aluminum welding often requires an inert gas to prevent oxidation, a cylinder of argon gas is essential for both TIG and MIG welding. The purity of the argon gas used affects the quality of the weld, making it important to use high-quality gas free of contaminants.

- Clamping Tools: Securely holding the aluminum pieces in place during the welding process is critical to ensure alignment and prevent warping. Clamps and jigs designed for aluminum can help maintain the integrity of the workpiece while welding.

- Cleaning Equipment: Proper cleaning tools, such as wire brushes or chemical cleaners, are necessary to remove oxide layers and contaminants from the aluminum surface before welding. This step is vital to achieving strong, defect-free welds and prolonging the life of the welding equipment.

Which Welding Machines Are Most Suitable for Working with Aluminum?

The best welding machines for working with aluminum include the following options:

- TIG Welders: Ideal for precise and clean welds on aluminum, especially for thin materials.

- MIG Welders: Suitable for both beginners and experienced welders, providing speed and ease of use for aluminum projects.

- Stick Welders: While less common for aluminum, they can be used with specific electrodes for certain applications.

- Multi-Process Welders: Versatile machines that can handle various welding processes, allowing for flexibility when working with aluminum.

TIG Welders: Tungsten Inert Gas (TIG) welding is known for producing high-quality welds with excellent control, making it perfect for aluminum. The process allows for precise adjustments and is suitable for thin sections, although it requires more skill and is generally slower than other methods.

MIG Welders: Metal Inert Gas (MIG) welding is favored for its speed and ease, especially for thicker aluminum pieces. This method uses a continuous wire feed, making it easier for beginners to achieve good results, and it is ideal for projects that require a faster turnaround without sacrificing weld quality.

Stick Welders: Shielded Metal Arc Welding (SMAW), or stick welding, is not the most common choice for aluminum due to its limitations, but it can be effective when using specific aluminum electrodes. It’s generally more suited for outdoor applications or situations where portability is essential, though it may not produce the cleanest welds.

Multi-Process Welders: These machines combine the functions of TIG, MIG, and stick welding, making them adaptable for various materials and situations. They offer the flexibility to switch processes depending on the project requirements, which is particularly useful for welders who frequently work with different metals, including aluminum.

What Are the Best Filler Materials for Welding Aluminum Effectively?

The best filler materials for welding aluminum effectively include:

- 4047 Aluminum Filler Rod: This filler rod is primarily composed of aluminum and silicon, which helps improve fluidity and reduces the risk of cracking during the welding process.

- 5356 Aluminum Filler Rod: Known for its high strength and corrosion resistance, this filler rod is ideal for welding applications where strength is a critical factor, such as in marine environments.

- 4045 Aluminum Filler Rod: Often used for brazing, this filler material is characterized by its good wetting properties and is typically alloyed with silicon and aluminum, making it suitable for welding thin materials.

- 5183 Aluminum Filler Rod: This rod offers excellent resistance to corrosion and is particularly suitable for applications that require high strength, such as pressure vessels and shipbuilding.

- 1100 Aluminum Filler Rod: Composed mostly of pure aluminum, this filler is recommended for welding applications that require good ductility and corrosion resistance, though it is not as strong as other alloys.

The 4047 Aluminum Filler Rod is favored for its ability to fill gaps and produce smooth welds, making it a popular choice for intricate designs and repairs. Its silicon content enhances fluidity, allowing for better penetration and reducing the likelihood of defects.

The 5356 Aluminum Filler Rod is particularly useful for welding aluminum to magnesium alloys, providing high strength and durability, which makes it ideal for structural applications. Its resistance to cracking makes it a favorite in industries that require reliable and robust welds.

The 4045 Aluminum Filler Rod is often used in automotive and aerospace applications due to its excellent joining properties and ability to create strong bonds on thinner materials. Its unique composition allows it to flow easily into joints, ensuring a consistent weld.

The 5183 Aluminum Filler Rod is commonly used in demanding environments such as shipbuilding and pressure vessel manufacturing, where strength and corrosion resistance are paramount. Its excellent mechanical properties under various conditions make it a top choice for heavy-duty applications.

The 1100 Aluminum Filler Rod, while not the strongest option, is excellent for applications that prioritize ease of welding and good corrosion resistance. It is often used for food and chemical processing equipment due to its purity and non-reactive nature.

What Common Challenges Will You Face When Welding Aluminum?

When welding aluminum, several common challenges can arise that need to be addressed for successful results.

- Oxidation: Aluminum forms a thin layer of aluminum oxide when exposed to air, which has a higher melting point than the base metal. This oxide layer can prevent proper fusion between the aluminum pieces being welded, leading to weak joints if not adequately removed before welding.

- Thermal Conductivity: Aluminum has high thermal conductivity, which can lead to rapid heat dissipation. This characteristic can make it difficult to maintain the necessary temperatures for welding, often requiring higher amperages or specialized techniques to ensure proper melting and fusion of the material.

- Distortion: Due to aluminum’s low melting point, it is more prone to warping and distortion during the welding process. This can complicate the alignment of parts and may require additional steps to manage heat input, such as using fixtures or preheating, to minimize distortion.

- Porosity: Aluminum can easily absorb hydrogen during the welding process, leading to porosity in the welds. This occurs when moisture or contaminants are present, which can cause bubbles to form in the weld bead, compromising the structural integrity of the joint.

- Welding Fumes: The welding of aluminum can produce harmful fumes and gases, especially when alloying elements are present. Proper ventilation and safety measures are necessary to protect welders from inhaling these fumes, which can pose health risks.

How Can You Avoid Warping and Distortion During Aluminum Welding?

To avoid warping and distortion during aluminum welding, several effective techniques and practices can be employed:

- Preheating the Aluminum: Preheating helps to reduce thermal stress by evenly distributing heat across the material. This process can minimize the temperature differential that leads to warping, especially in thicker sections of aluminum.

- Controlling the Heat Input: Adjusting the welding parameters such as voltage, amperage, and travel speed can help maintain a consistent heat input. Too much heat can cause excessive melting and distortion, while too little can lead to weak welds.

- Using Proper Fixture and Clamping: Securely clamping the aluminum pieces before and during welding keeps them in place and reduces movement caused by thermal expansion. Proper fixtures can also help maintain alignment and reduce the chances of distortion.

- Weld Sequence Planning: Implementing a strategic welding sequence, such as alternating sides or using skip welding techniques, can help minimize the buildup of heat in one area. This approach allows for the natural cooling of the weld, reducing the likelihood of warping.

- Choosing the Right Filler Material: Selecting an appropriate filler material that complements the base aluminum can improve the overall weld integrity. It’s important to choose a filler that has similar thermal expansion characteristics to the base material to minimize distortion.

- Post-Weld Treatment: Applying techniques such as stress relieving or heat treatment after welding can help to alleviate any residual stresses that may have developed during the welding process. This can further reduce the chances of warping and ensure the structural integrity of the welded assembly.

What Techniques Are Effective for Managing Oxidation in Aluminum Welding?

Effective techniques for managing oxidation in aluminum welding ensure high-quality joints and prevent defects.

- Cleaning the Surface: Prior to welding, it’s crucial to clean the aluminum surface using solvents or mechanical methods to remove any oxide layer, dirt, or contamination. This step ensures better weld penetration and reduces the risk of porosity and other welding defects.

- Using Filler Materials: Selecting the appropriate filler material that is compatible with the aluminum base can help manage oxidation. Filler materials designed for aluminum often have lower melting points and can melt and flow into the joint, helping to displace oxide and promote a stronger bond.

- Controlling Heat Input: Proper heat management during welding is vital to prevent excessive oxidation. By adjusting the welding parameters, such as voltage and travel speed, welders can maintain optimal temperatures that minimize oxidation while ensuring proper fusion.

- Shielding Gas Utilization: Employing an inert shielding gas like argon during the welding process protects the molten weld pool from atmospheric contamination. This protective layer helps to prevent oxidation and maintains the integrity of the weld.

- Welding Technique: Utilizing specific welding techniques, such as the push or pull technique, can influence the amount of oxidation that occurs. For instance, the push technique often minimizes exposure to air, reducing oxidation during the weld process.

What Safety Precautions Should You Follow While Welding Aluminum?

When welding aluminum, several safety precautions should be adhered to in order to ensure a safe working environment and effective results.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including a welding helmet with the correct shade, gloves, and protective clothing to shield against ultraviolet light and sparks.

- Ventilation: Ensure proper ventilation in the workspace to avoid inhaling harmful fumes and gases produced during the welding process.

- Fire Safety: Keep a fire extinguisher nearby and clear the work area of flammable materials to mitigate fire hazards associated with welding activities.

- Tool Maintenance: Use well-maintained and appropriate tools for aluminum welding, including clean welding nozzles and electrodes, to prevent accidents and ensure quality welds.

- Electrical Safety: Be aware of electrical hazards by ensuring equipment is grounded, using insulated tools, and avoiding contact with wet surfaces when welding.

- Proper Setup: Securely position the aluminum workpieces and ensure they are stable to prevent shifting or falling during the welding process.

Wearing appropriate PPE is crucial as it protects the welder from harmful UV radiation emitted during the welding process, as well as potential burns from molten metal. Gloves and durable clothing can prevent skin injuries from sparks and heat.

Proper ventilation is essential since aluminum welding can produce harmful fumes, including ozone and other toxic substances. A well-ventilated area helps ensure that these harmful substances are dispersed, minimizing inhalation risks.

Fire safety measures are critical because welding can ignite nearby flammable materials due to high temperatures and sparks. Keeping an extinguisher on hand and removing combustibles from the work area can significantly reduce the risk of a fire outbreak.

Maintaining tools in good condition is necessary to avoid malfunctions that could lead to accidents. Clean welding nozzles and electrodes not only enhance the quality of welds but also reduce the chances of electrical faults.

Electrical safety involves ensuring that all welding equipment is properly grounded and that insulated tools are used to prevent electric shock. Being cautious around wet surfaces is vital, as moisture increases the risk of electrical complications.

Lastly, ensuring that aluminum workpieces are properly secured and stable can prevent unexpected movements that might lead to injuries. A well-organized workspace with securely positioned materials promotes a safer welding environment.

What Protective Gear Is Essential for Safe Aluminum Welding?

The essential protective gear for safe aluminum welding includes various items designed to safeguard the welder from hazards associated with the process.

- Welding Helmet: A welding helmet is crucial as it protects the eyes and face from harmful ultraviolet (UV) and infrared (IR) radiation produced during the welding process. It also shields against sparks, spatter, and heat, ensuring the welder can work safely without risking severe burns or eye damage.

- Gloves: High-quality welding gloves are essential to protect the hands from extreme heat, electric shock, and sharp materials. They are typically made from durable leather or other heat-resistant materials, providing both dexterity and safety while handling hot components or welding materials.

- Protective Clothing: Flame-resistant clothing, such as long-sleeved shirts and pants, is vital for shielding the skin from sparks and spatter. These garments should be made from materials that do not ignite easily, helping to prevent burns and injuries during the welding process.

- Respirator: A respirator is necessary when welding aluminum, as it helps filter out harmful fumes and particulates that can be released during the welding process. Proper respiratory protection is essential in maintaining lung health and preventing respiratory issues related to inhalation of toxic substances.

- Safety Boots: Steel-toed safety boots are important for protecting the feet from falling objects and heavy equipment. They also provide slip resistance and support, which is necessary when working in environments where there may be hazards on the ground.

- Face Shield: A face shield offers additional protection for the face, particularly when performing tasks that may result in flying debris or spatter. It is often used in conjunction with a helmet for comprehensive facial protection while welding aluminum.

- Hearing Protection: Depending on the environment, hearing protection such as earplugs or earmuffs may be necessary to guard against the loud noises associated with welding equipment. Prolonged exposure to high decibel levels can lead to hearing damage, making this protective gear an important consideration.

How Can You Ensure Adequate Ventilation When Welding Aluminum?

Ensuring adequate ventilation when welding aluminum is crucial for safety and quality of work.

- Use of Fume Extractors: Fume extractors are essential tools that capture and filter harmful fumes generated during the welding process. They improve air quality by reducing exposure to toxic substances, especially when working in confined spaces.

- Work in Open Spaces: Whenever possible, welding should be done outdoors or in well-ventilated areas to allow for natural airflow. This helps dissipate fumes and prevents them from accumulating around the welder.

- Use of Fans: Utilizing fans can significantly enhance ventilation by circulating air and directing fumes away from the welder’s breathing zone. Positioning fans strategically can help create a cross breeze that aids in effective fume removal.

- Welding Booths with Ventilation Systems: Setting up a dedicated welding booth equipped with a built-in ventilation system provides controlled airflow specifically designed to remove welding fumes. These systems can be customized to meet the specific needs of the workspace.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as respirators designed for welding, can protect against inhalation of harmful fumes even in less-than-ideal ventilation conditions. This is a critical safety measure that complements other ventilation strategies.