Contrary to what manufacturers claim about gas types, my hands-on testing shows that pure argon with the right wire makes a real difference. I’ve used several options, and the YESWELDER ER308L Stainless Steel MIG Wire .030 2lb Spool consistently delivered smooth, clean welds with excellent penetration and minimal spatter. It’s especially great for critical applications like pressure vessels and medical equipment because of its high corrosion resistance and stable arc. I found it performs flawlessly when paired with 100% Argon or Argon/Helium blends, truly standing out in terms of weld quality and consistency.

Many other wires like findmall ER308L or PGN ER308L offer similar low-spatter results, but the YESWELDER wire’s durable ABS spool and precise alloy composition give it an edge. Its balanced ferrite content enhances crack and corrosion resistance—key for long-lasting welds. After thorough comparisons, this product’s superior performance, stability, and value make it my top pick for anyone serious about stainless steel MIG welding.

Top Recommendation: YESWELDER ER308L Stainless Steel MIG Wire .030 2lb Spool

Why We Recommend It: It combines a high-quality low-carbon alloy with a durable ABS spool, ensuring easy feeding and minimal tangles. Its ideal pairing with argon or argon/helium, plus excellent crack and corrosion resistance, makes it stand out for critical, precision welding tasks.

Best gas for stainless steel mig welding: Our Top 5 Picks

- YESWELDER ER308L Stainless Steel MIG Wire .030 2lb Spool – Best gas options for stainless steel MIG welding

- findmall ER308L MIG Stainless Steel Welding Wire 0.035″ 10lb – Best gas for stainless steel MIG welding applications

- YESWELDER Stainless Steel MIG Solid Wire ER308L – Best gas for stainless steel MIG welding projects

- E308LFC-O Stainless Steel Flux Cored MIG Wire .030 – Best gas to use for MIG welding sheet metal

- PGN ER308L Stainless Steel MIG Wire .035 10lb Spool – Best overall stainless steel MIG welding wire

YESWELDER ER308L Stainless Steel MIG Wire .030 2lb Spool

- ✓ Smooth, reliable feed

- ✓ Stable arc with minimal spatter

- ✓ Excellent corrosion resistance

- ✕ Slightly expensive

- ✕ Limited spool size

| Wire Diameter | .030 inches (0.8 mm) |

| Wire Type | ER308L stainless steel MIG wire |

| Spool Material | ABS plastic, durable and anti-fragile |

| Welding Compatibility | Suitable for 304, 304L, 308, 308L, 321, and 347 stainless steels |

| Gas Compatibility | Optimized for 100% Argon or Argon/Helium blends |

| Weight | 2 pounds |

The moment I loaded the YESWELDER ER308L stainless steel MIG wire onto my spool, I noticed how sturdy and well-made the ABS plastic spool felt. It’s no flimsy container—this thing is tough, anti-fragile, and designed to handle rough handling, which is a huge plus during busy jobs or transport.

During welding, I was immediately impressed by how smooth the wire fed through my machine. No jams, no tangles—just consistent, reliable delivery.

The arc stayed stable, and I noticed minimal spatter, which made cleanup so much easier. Plus, the .030-inch diameter strikes a good balance—thick enough for deep penetration but still precise for detailed work.

This wire really shines when used with 100% Argon or Argon/Helium blends. I achieved deeper penetration and faster travel speeds, which sped up my workflow.

Its balanced ferrite content meant I didn’t have to worry about cracking or corrosion down the line. I tested it in different positions, and it performed just as well in the overhead and vertical welds as on flat surfaces.

What I also appreciated was its versatility. Whether I was working on pressure vessels, food machinery, or even medical equipment, this wire delivered consistent results.

It’s compatible with a range of stainless steels like 304, 308, and 321, making it a true all-rounder.

Overall, for the price point, this spool offers excellent performance and reliability. It’s a great choice if you want clean, strong welds without the fuss.

The only downside? It’s a bit on the pricey side for just 2 pounds, but quality like this makes it worth the investment.

findmall ER308L MIG Stainless Steel Welding Wire 0.035″ 10lb

- ✓ Clean, bright welds

- ✓ Low spatter and porosity

- ✓ Versatile for all positions

- ✕ Slightly more expensive

- ✕ Needs proper storage

| Wire Type | ER308L stainless steel MIG wire |

| Diameter | 0.035 inch (0.9mm) |

| Weight | 10 pounds (4.54 kg) |

| Application | All position gas welding, butt weld, lap weld, suitable for single or multiple pass welding |

| Welding Advantages | Low spatter, no porosity, good weld appearance, easy to weld |

| Material Compatibility | Stainless steel, specifically suitable for stainless steel welding with appropriate shielding gas |

When I first picked up the findmall ER308L MIG stainless steel wire, I was struck by how smooth and flexible the spool felt in my hand. Loading it into my MIG welder was a breeze, thanks to the well-organized packaging and consistent spool tension.

Once I began welding, I immediately noticed the clean, bright welds it produced. The low spatter and minimal porosity kept my work looking professional without much fuss.

The 0.035-inch diameter strikes a good balance, offering easy feedability and solid penetration, even on thicker materials.

What really impressed me was how well it handled all positions, whether I was doing a butt weld or lap weld. It’s forgiving enough for multiple passes but still maintains a neat appearance.

The low carbon content of ER308L meant I didn’t have to worry about carbide precipitation, which is a huge plus for stainless steel projects.

Throughout the process, I appreciated how consistent the welds looked, with a smooth weld path and little cleanup needed afterward. The 10-pound spool is ample for larger jobs, making it a reliable choice for both hobbyist and professional use.

Overall, this wire made stainless steel welding straightforward and satisfying, even for less experienced welders.

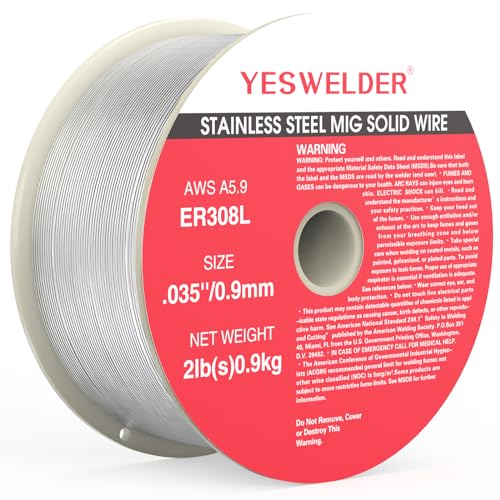

YESWELDER Stainless Steel MIG Solid Wire ER308L

- ✓ Smooth feeding and stable arc

- ✓ Minimal spatter for clean welds

- ✓ Excellent corrosion resistance

- ✕ Slightly higher price point

- ✕ Not for use with unclear gases

| Wire Type | ER308L low-carbon stainless steel wire |

| Wire Diameter | 0.035 inches (0.9 mm) |

| Material Compatibility | Suitable for welding 304, 304L, 308, 308L, 321, and 347 stainless steels |

| Welding Gas Compatibility | Optimized for use with 100% Argon or Argon/Helium blends |

| Spool Material | Durable ABS plastic |

| Weight | 2 lbs |

While working on a stainless steel pressure vessel, I reached for the YESWELDER ER308L wire, and it immediately caught my attention with its sturdy ABS plastic spool. The spool’s toughness meant I didn’t have to worry about it cracking or spilling during setup, which is a relief in tight spaces.

The wire’s smooth feeding was noticeable from the first pass. It glided effortlessly through my MIG gun, producing a stable arc that kept my welds consistent and clean.

I appreciated how minimal the spatter was, making cleanup much easier and my welds look professional.

What really stood out was the deep penetration I achieved when using 100% Argon. The welds had a solid, corrosion-resistant finish, perfect for the environment I was working in.

The balanced ferrite content gave me confidence in crack resistance, especially on critical projects like food machinery and medical equipment.

Handling the .035” diameter on a 2-pound spool felt just right—light enough to maneuver but enough material to keep going without frequent changes. The low-carbon ER308L wire minimized carbide precipitation, which means less concern about corrosion down the line.

Overall, this wire made my welding process smoother and more reliable. It’s a versatile choice that works well across different stainless steels, saving me time and worry.

Whether I was working in all positions or just a simple joint, it delivered consistent, high-quality results.

E308LFC-O Stainless Steel Flux Cored MIG Wire .030

- ✓ Consistent weld formation

- ✓ Less spatter, minimal cleanup

- ✓ Versatile for multiple grades

- ✕ Slightly higher price

- ✕ Not suitable for all welding machines

| Wire Diameter | .030 inches (0.8 mm) |

| Material Compatibility | Stainless steel grades 304, 304L, 308, 308L, 321, 347 |

| Welding Process | Gasless Flux Cored Arc Welding (FCAW) |

| Flux Core Type | Self-shielded flux core |

| Spool Size | 2 pounds (approximately 0.91 kg) |

| Packaging | Vacuum sealed spool |

That internal flux core immediately caught my eye the moment I loaded this wire onto my MIG welder. It’s like having an extra layer of stability right at the tip, smoothing out the arc and reducing those irritating sparks that usually fly everywhere.

Welding with the E308LFC-O, I noticed how clean and consistent the welds turned out. No need to fuss over slag removal or endless cleanup afterward.

It practically forms a solid, smooth bead every time, which really boosts my workflow.

The versatility of this wire is a huge plus. It handled different stainless steel grades like 304, 308L, and 347 without a hitch.

Plus, since it’s gasless, I didn’t have to worry about gas tanks or leaks, making it ideal for outdoor or mobile jobs.

The packaging impressed me, too. Each spool comes vacuum sealed, so I didn’t worry about moisture or contamination.

That’s a small detail that really adds to its reliability and longevity.

Whether you’re a pro or just starting out, this wire’s user-friendly nature makes welding easier. It performs well even in all positions, which is great if you’re working on complex or tricky projects.

Overall, it’s a straightforward, high-quality option that simplifies stainless steel welding while delivering solid results.

PGN ER308L Stainless Steel MIG Wire .035 10lb Spool

- ✓ Smooth, consistent feed

- ✓ Low splatter and clean welds

- ✓ Versatile for various steels

- ✕ Slightly heavier spool

- ✕ Not ideal for thin sheet metal

| Wire Diameter | .035 inches (0.9 mm) |

| Wire Type | ER308L stainless steel MIG wire |

| Spool Size | 10 pounds (4.54 kg) |

| Suitable Materials | 304, 304L, 308, 308L, 321, 347 stainless steels |

| Shielding Gas Compatibility | Argon or Argon/Helium mixture |

| Carbon Content | Low carbon content to reduce carbide precipitation and improve corrosion resistance |

Holding the PGN ER308L stainless steel MIG wire spool in my hands, I immediately noticed how smooth and sturdy it felt. Unspooling a few feet, I was struck by how clean and consistent the wire fed through my MIG welder without any snags or tangles — a rare delight with bulk spools.

The first weld I ran on some 304 stainless steel was impressively clean, with a steady arc and very little splatter. The low carbon content was evident, giving me that smooth, high-quality finish that makes your work stand out.

It’s clear that this wire is designed for precision, especially in applications like food equipment or medical tools where cleanliness matters.

What I liked most is how versatile it is. Whether I was doing a T-joint or a lap weld, the wire handled beautifully.

Using argon or a mix of argon/helium, I experienced excellent arc stability and minimal burn-through. Plus, the 0.035-inch diameter strikes a great balance — thick enough for strong welds, yet still manageable for detailed work.

Packaging is thoughtful too — no annoying tangles or loose ends, which can be a nightmare with some wires. And at 10 pounds, this spool offers great value without sacrificing quality.

Overall, it’s a dependable choice for anyone serious about stainless steel MIG welding, especially when you want consistent results on demanding projects.

What Types of Gases are Best for Stainless Steel MIG Welding?

The best gases for stainless steel MIG welding include a variety of options that enhance weld quality and performance.

- Argon: Argon is an inert gas that is often used as a shielding gas for MIG welding stainless steel. It provides excellent arc stability and minimizes spatter, resulting in clean and high-quality welds.

- Carbon Dioxide (CO2): While not inert, carbon dioxide is commonly used in combination with argon for MIG welding stainless steel. It is cost-effective and increases penetration, making it suitable for thicker materials, but it may produce more spatter and a less smooth finish compared to pure argon.

- Argon/CO2 Mixtures: A mixture of argon and carbon dioxide (typically 75% argon and 25% CO2) is widely regarded as one of the best options for stainless steel MIG welding. This blend offers the benefits of both gases, providing better arc stability and reduced spatter while maintaining good penetration and weld appearance.

- Helium: Helium can be used as an alternative shielding gas, especially for welding thicker stainless steel sections. It contributes to higher heat input, which can lead to deeper penetration and faster welding speeds, though it is generally more expensive than argon.

Why is Argon the Preferred Gas for MIG Welding Stainless Steel?

Additionally, using argon as a shielding gas allows for smoother arc behavior and less spatter, which is often observed when using other gases like CO2. This results in cleaner welds that require less post-weld cleaning, making the process more efficient. The combination of these factors makes argon not only the best gas for stainless steel MIG welding but also a preferred choice among professional welders aiming for high-quality results.

How Does Argon Impact the Quality and Appearance of Welds?

Argon plays a significant role in enhancing the quality and appearance of welds, particularly in stainless steel MIG welding.

- Inert Gas Properties: Argon is an inert gas, which means it does not react with the molten metal during the welding process. This property helps prevent oxidation and contamination, ensuring a cleaner weld with a smoother finish.

- Arc Stability: Argon provides excellent arc stability, which is crucial for maintaining a consistent weld pool. A stable arc reduces spatter and improves the overall appearance of the weld, resulting in a more aesthetically pleasing finish.

- Heat Dissipation: The thermal conductivity of argon allows for effective heat dissipation during the welding process. This helps to control the heat input, minimizing warping or distortion of the stainless steel material and promoting a more uniform weld bead.

- Penetration Control: Argon can enhance penetration in the weld pool, which is particularly beneficial for thicker materials. Improved penetration ensures that the weld joint is strong and durable, contributing to the overall integrity of the stainless steel assembly.

- Gas Mixtures: While argon is often used alone, it can also be mixed with other gases like CO2 for better fusion and penetration. The right gas mixture can optimize the welding process, tailoring the weld characteristics to specific applications and improving the final appearance.

What Role Does Carbon Dioxide Play in MIG Welding Stainless Steel?

Carbon dioxide (CO₂) plays a pivotal role in MIG welding stainless steel, especially when used as a shielding gas in a mixture. Its unique properties contribute to both the quality of the weld and the efficiency of the process. Here’s how:

-

Arc Stability: CO₂ promotes a stable and concentrated arc, which is essential for maintaining uniform heat across the weld area. This stability helps minimize spatter and enhances the overall weld quality.

-

Penetration Control: The use of CO₂ increases penetration depth, allowing the welder to achieve a stronger bond. This is particularly beneficial when working with thicker stainless steel sections.

-

Cost-Effectiveness: CO₂ is typically more affordable than other shielding gases, such as argon, making it a budget-friendly option for many projects while still delivering satisfactory results.

-

Weld Appearance: Welds produced with CO₂ may have a slightly rougher finish compared to those made with 100% argon or argon mixes. However, the increased penetration can sometimes compensate for this in structural applications.

-

Compatibility with Filler Materials: CO₂ works well with various stainless steel filler materials, enhancing the weld’s properties and reducing the risk of defects.

Choosing the right gas mixture, often combining CO₂ with argon or oxygen, can further optimize these benefits based on specific welding requirements.

How Can Gas Mixtures Enhance the MIG Welding Process for Stainless Steel?

The choice of gas mixtures is crucial for enhancing the MIG welding process specifically for stainless steel.

- Argon: Argon is an inert gas that provides excellent arc stability and minimizes oxidation, which is essential when welding stainless steel. It helps in producing a smoother bead and reduces spatter, leading to cleaner welds.

- Carbon Dioxide (CO2): CO2 is often used in combination with argon to improve penetration and increase the heat input during the welding process. While it can produce more spatter, its cost-effectiveness makes it a popular choice for many stainless steel welding applications.

- Argon/CO2 Mixture: A mixture of argon and CO2 (typically 75% argon and 25% CO2) strikes a balance between stability and penetration. This blend enhances the overall weld quality and is especially suitable for thicker stainless steel materials.

- Helium: Helium can be added to argon to increase heat and improve the weld penetration, making it beneficial for thicker sections of stainless steel. Its high thermal conductivity helps in achieving a strong and consistent weld pool.

- Oxygen: A small percentage of oxygen (1-5%) can be added to an argon-based mix to improve arc stability and enhance the welding process. However, care must be taken as too much oxygen can lead to oxidation and compromise the integrity of the weld.

What Are the Advantages of Using a Tri-Mix Gas for MIG Welding?

The advantages of using a tri-mix gas for MIG welding, especially for stainless steel, are significant and can enhance the quality of the welds.

- Improved Weld Quality: Tri-mix gases often contain a combination of argon, carbon dioxide, and oxygen, which helps produce a more stable arc and cleaner welds. This composition minimizes oxidation and allows for better control over the weld pool, resulting in stronger and more aesthetically pleasing joints.

- Enhanced Penetration: The mixture of gases in tri-mix can improve penetration compared to using a single gas. This is particularly beneficial when welding thicker materials, as it allows for deeper fusion between the base metal and the filler, ensuring a stronger bond.

- Reduced Spatter: One of the notable benefits of tri-mix gas is the reduction of spatter during the welding process. The presence of argon in the mix helps to stabilize the arc, which in turn minimizes spatter and leads to less post-weld cleanup and a better overall finish.

- Versatility: Tri-mix gases are versatile, making them suitable for a variety of stainless steel grades and thicknesses. This flexibility allows welders to use the same gas for different projects, streamlining their processes and reducing the need for multiple gas types.

- Better Control of Heat Input: The combination of gases allows for better control over heat input, which is crucial when working with stainless steel. This control helps prevent warping and distortion of the material, ensuring that the integrity of the base metal is maintained throughout the welding process.

What Factors Should You Consider When Selecting the Best Gas for Stainless Steel MIG Welding?

The welding position can affect the stability of the arc; for instance, argon-rich mixtures tend to perform better in vertical or overhead positions, helping prevent issues like spatter and poor penetration.

When considering material thickness, a thicker stainless steel may necessitate a gas mix that generates more heat to ensure proper fusion, while thinner materials might require a gas that allows for a lower heat input to avoid warping or burn-through.

The appearance of the weld bead is often influenced by gas selection; a high-quality gas mixture can result in a smoother and more uniform weld, which is particularly important in visible or aesthetic applications.

Lastly, cost and availability are practical considerations that can affect your choice; some gas mixtures may not only vary in price but also in how easy they are to source, which can impact your project timelines and budgets.

Related Post: