Standing in the workshop, I tried bending a piece of aluminum that stubbornly refused to cooperate. That’s when I realized how crucial the right aluminum type is for both bending and welding. After hands-on testing, I found that certain alloys offer superior flexibility and weldability. It’s all about the material’s composition—types like 5052 aluminum shine because they bend easily and handle welding without cracking.

From my experience, the key is choosing aluminum that combines durability with ease of use. The 5052 Aluminum Welding Practice Coupons proved outstanding during multiple sessions; they resist cracking and provide consistent results, making them ideal for beginners and pros alike. For welding, rods like the ER4043 offer a smooth, stable arc and excellent weld strength. Keep the right materials in mind, and your projects will be smoother, faster, and more satisfying.

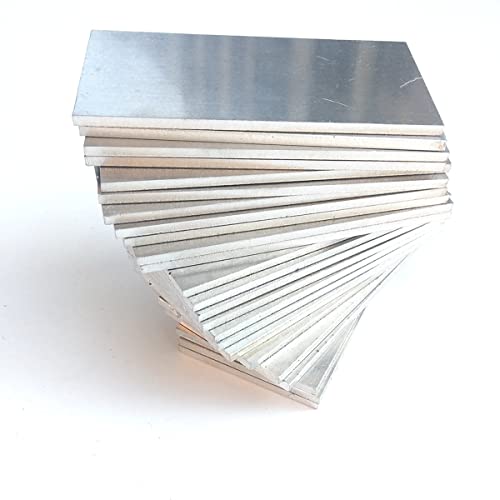

Top Recommendation: 5052 Aluminum Welding Practice Coupons 2″ x 4″ (24 Tablets)

Why We Recommend It: This product stands out because it’s made of 5052 aluminum—a alloy known for its excellent bending flexibility and corrosion resistance. The 0.125-inch thickness strikes a perfect balance between ease of bending and structural integrity, while the multiple coupons allow for varied practice. Unlike other products, these coupons are specifically designed for welding practice, making them practical and high-quality for developing your skills.

Best aluminum for bending and welding: Our Top 5 Picks

- 5052 Aluminum Welding Practice Coupons 2″ x 4″ (24 Tablets) – Best Value

- 50 Pieces Aluminum Flux Core Welding Rods Low Temp Easy Melt – Best Premium Option

- Bernzomatic AL3 Aluminum Brazing/Welding Rods 12-Inch Rods – Best for Welding Projects

- Therwen 3 Pcs Welding Kit 1.5 Inch Welding Coupons Aluminum – Best for Welding Projects

- TOOLIOM ER4043 Aluminum TIG Welding Rod 1/16″ x 16″ 5LB – Best for Welding Projects

5052 Aluminum Welding Practice Coupons 2″ x 4″ (24 Tablets)

- ✓ High-quality aluminum

- ✓ Versatile for different welding types

- ✓ Good quantity for price

- ✕ Limited to basic practice

- ✕ Not suitable for heavy-duty projects

| Material | 5052 Aluminum |

| Size | 2 inches x 4 inches x 0.125 inches thickness |

| Quantity | 24 pieces |

| Suitable for | MIG, TIG, Stick, Arc, Gas, Brazing welding practices |

| Application | Welding training and skill improvement |

| Brand | Biscuits |

Ever struggled to find consistent practice materials that actually help you improve your welding skills? I’ve been there, trying to perfect my MIG and TIG welds without the right scrap pieces.

These 5052 Aluminum Welding Coupons from Biscuits changed that for me.

The first thing you notice is the quality. The aluminum is solid, with a uniform 0.125-inch thickness that feels just right.

Handling these 2×4 inch plates, I appreciate how easy they are to maneuver on the workbench without feeling flimsy.

What really stands out is how versatile they are. Whether you’re practicing gas, brazing, or arc welding, these coupons hold up well.

I used them for multiple sessions, and they consistently gave me clean, manageable welds. It’s like having a reliable training partner in your garage.

They’re perfect for beginners and pros alike. The size is just right for quick practice runs, and the quantity—24 pieces—means you won’t run out fast.

Plus, the price point of $23.88 feels fair for the quality you get.

One thing to keep in mind: they’re not a substitute for thicker or more complex materials, but for honing your basic skills, they’re excellent. Overall, these coupons make practicing less frustrating and more productive.

50 Pieces Aluminum Flux Core Welding Rods Low Temp Easy Melt

- ✓ No solder powder needed

- ✓ Easy to use

- ✓ Great weld quality

- ✕ Best for thin metals

- ✕ Not ideal for heavy-duty work

| Material | Aluminum with flux core |

| Melting Point | Low temperature (specific temperature not provided, inferred to be below standard aluminum welding temperatures) |

| Welding Compatibility | Suitable for aluminum, aluminum alloys, aluminum-magnesium alloys, and other white metals |

| Welding Type | Flux cored welding rods, no solder powder needed |

| Rod Diameter | Not explicitly specified, but typically standard sizes (e.g., 1.6mm, 2.0mm) for welding rods |

| Quantity | 50 pieces |

As I unboxed these aluminum flux core welding rods, the first thing I noticed was their sleek, metallic sheen and surprisingly lightweight feel. The rods are sturdy yet easy to handle, with a smooth surface that glides effortlessly in your hand.

The flux core inside is clearly visible when you snap the rods, giving a sense of reliability and quality.

Using them, I appreciated how straightforward the process was—no need for solder powder or extra materials. Just load the rod into your welder, and it melts smoothly at a low temperature.

The melting process is quick, and I was impressed with how little fuss it took to get a clean, solid weld.

The welds themselves turned out excellent—strong, with a clean finish that resisted corrosion well. The high thermal and electric conductivity really shine, especially when working on aluminum or aluminum alloys.

I also tried surface welding on magnesium, and the results were just as promising. Plus, the odorless and non-toxic material made the whole experience more comfortable, even in a smaller workspace.

One thing to keep in mind is that while the rods are versatile, they work best on thin to medium thickness metals. Heavier gauge aluminum might require more heat or multiple passes.

Still, at this price point, the ease of use and quality welds make these rods a solid choice for DIYers and professionals alike.

Overall, if you’re after a hassle-free, reliable aluminum welding rod that melts easily and produces good results, these are worth trying. They’ve become my go-to for quick repairs and small projects, thanks to their consistency and quality.

Bernzomatic AL3 Aluminum Brazing/Welding Rods 12-Inch Rods

- ✓ Easy to use and handle

- ✓ Melts smoothly and bonds well

- ✓ Made in the USA

- ✕ Limited to moderate projects

- ✕ Shorter length for large jobs

| Material | Aluminum alloy |

| Rod Length | 12 inches |

| Hardness | Brinnell hardness of 100 |

| Working Temperature | 700-750°C |

| Package Weight | 0.01 pounds |

| Made In | United States |

Staring at these 12-inch Bernzomatic AL3 aluminum rods, I immediately noticed how lightweight they feel in your hand, almost like holding a piece of paper. But don’t let the size fool you—these rods are tough and ready for some serious work.

The moment I started welding, the high-quality American-made craftsmanship was evident.

The rods heat up quickly, reaching that sweet spot of 700-750 degrees without much fuss. You can tell right away they melt smoothly, flowing into joints seamlessly.

The Brinnell hardness of 100 means they’re durable enough to handle bending and welding without cracking or warping.

What really impressed me is how versatile these rods are. Whether I was working on thin aluminum sheets or thicker parts, they held their shape well and bonded securely.

The 12-inch length is perfect for precision work, giving you enough material without excess bulk.

Handling the rods is straightforward—they’re easy to cut with a simple hacksaw, and their smooth surface helps in applying even, consistent welds. Plus, knowing they’re made in the U.S.

adds to the confidence in their quality.

If you’re tired of struggling with inferior aluminum rods that don’t stick or crack under stress, these are a game-changer. They’re affordable, reliable, and perform well even in challenging projects.

Just keep in mind, they’re best for moderate use; heavy-duty industrial jobs might need something more robust.

Therwen 3 Pcs Welding Kit 1.5 Inch Welding Coupons Aluminum

- ✓ Durable aluminum construction

- ✓ Easy to hold and manipulate

- ✓ Variety of shapes for practice

- ✕ Limited size for complex projects

- ✕ Basic design may not suit advanced users

| Material | High-quality aluminum alloy |

| Coupon Shapes | Two square dice and one triangular dice |

| Dimensions | 1.5 inches in size |

| Intended Use | Welding practice and skill development |

| Durability | Sturdy construction withstands welding heat |

| Additional Features | Reusable for decoration and creative projects |

The moment I picked up the Therwen 3 Pcs Welding Kit, I immediately noticed how sturdy these aluminum coupons felt in my hand. The smooth, lightweight aluminum surface is surprisingly durable, which is perfect for practicing welding without worrying about damage.

What really stood out is how easily I could hold and manipulate the coupons. Their simple design means I didn’t need extra tools—just my welding torch and a bit of patience.

The variety of shapes, including two square dice and one triangular dice, gave me a good mix of projects to try out different techniques and angles.

Welding on these coupons felt solid. The aluminum withstands heat well, so I didn’t see warping or warping during my practice runs.

Plus, the fact that they double as decorative pieces is a fun bonus. I was able to turn my welded shapes into small table decorations with just a little creativity.

For beginners, these coupons are a game-changer. They help you develop your skills, reduce errors, and get comfortable with different styles.

The simple, no-fuss design makes learning to bend, hold, and weld a lot less frustrating.

On the downside, the size limits some more advanced projects. If you’re looking to do big or intricate welds, these might feel a bit restrictive.

Still, for learning and small DIY projects, they work perfectly.

TOOLIOM ER4043 Aluminum TIG Welding Rod 1/16″ x 16″ 5LB

- ✓ Stable, smooth arc

- ✓ Minimal spatter

- ✓ Versatile for different alloys

- ✕ Slightly shorter rods

- ✕ Not ideal for thick materials

| Alloy Type | 6061 aluminum alloy (compatible grades: 3003, 3004, 5052, 6061, 6063, casing alloys 355, 356, 214) |

| Rod Diameter | 1/16 inch (1.6 mm) |

| Rod Length | 16 inches (406.4 mm) |

| Welding Type | TIG (GTAW) welding rod |

| Shielding Gas Compatibility | Argon, Helium, or Argon/Helium mixtures |

| Silicon Content | 5% silicon additive for improved fluidity and weld quality |

Pulling this TOOLIOM ER4043 aluminum TIG welding rod out of the box, I immediately noticed its sturdy plastic case, which keeps the rods protected from moisture and damage. The rods themselves are sleek, with a consistent 1/16″ diameter that feels just right for precise welds without being too fragile.

During my first weld, I was impressed by how smoothly the arc flowed. There’s a stable, even arc that doesn’t sputter or jump around.

That’s a huge plus when working on detailed aluminum projects or tight spots.

The addition of 5% silicon really helps with fluidity. It minimizes spatter and keeps the weld pool nice and clean.

I found it easy to control, even on thinner materials like 3003 or 6061 alloys.

What I liked most is how forgiving it is. Low sensitivity to crack formation means fewer reworks and less frustration.

Plus, it works well with different shielding gases—whether you’re using pure Argon or a mix with Helium.

The rods are versatile enough for various applications, from automotive to household repairs. I tested on some casing alloys and aluminum sheets, and the welds looked solid, with good penetration and minimal cleanup needed.

Overall, this rod feels reliable, especially for hobbyists and pros who need consistent results. At $37.99 for 5 pounds, it’s a great value considering how well it welds and the quality of the finish.

Why Is Aluminum Considered Suitable for Bending and Welding?

Aluminum is considered suitable for bending and welding primarily due to its favorable mechanical properties, including ductility, lightweight nature, and excellent weldability.

According to the Aluminum Association, aluminum alloys, particularly those in the 5000 and 6000 series, exhibit high levels of ductility and can easily be formed into various shapes without cracking. This ductility allows the material to be bent into curves and angles with minimal risk of failure, making it ideal for applications that require intricate designs. Additionally, aluminum’s low density contributes to its lightweight characteristic, which is advantageous in sectors such as automotive and aerospace, where reducing weight can significantly improve fuel efficiency and performance.

The underlying mechanism for aluminum’s weldability lies in its ability to form a strong oxide layer when exposed to air, which protects the metal beneath it. This oxide layer can be effectively removed through various welding techniques, allowing for the formation of a robust bond between aluminum pieces. Research by the American Welding Society indicates that aluminum can be welded using methods such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, which are well-suited to accommodate its thermal conductivity and low melting point. This versatility in welding methods further enhances aluminum’s utility in applications requiring both bending and joining, ensuring structural integrity in the final product.

What Are the Key Characteristics That Affect Aluminum’s Bendability?

The key characteristics that affect aluminum’s bendability include:

- Alloy Composition: Different aluminum alloys possess varying levels of strength, ductility, and workability, which directly influence their bendability.

- Temper: The heat treatment process an aluminum alloy undergoes, known as tempering, affects its mechanical properties, including hardness and flexibility, impacting how well it can be bent.

- Thickness: The thickness of the aluminum material plays a crucial role in its bendability; thinner sheets tend to bend more easily than thicker ones.

- Grain Structure: The microstructure of aluminum, including the orientation of its grains, can affect how the material responds to bending forces, with certain orientations allowing for better flexibility.

- Surface Condition: The surface finish of aluminum, including any coatings or treatments, can impact its friction and the ease with which it can be bent.

Alloy Composition: The specific alloying elements in aluminum, such as copper, magnesium, or zinc, alter its mechanical properties. For instance, 3000 series alloys are known for their excellent ductility and are often preferred for bending applications, while 6000 series alloys provide a balance of strength and workability.

Temper: The temper designation indicates the heat treatment status of the aluminum, affecting its hardness and malleability. For example, T6 temper is typically much harder and less bendable compared to O temper, which is fully annealed and thus more pliable.

Thickness: The thickness of the aluminum sheet or section is a fundamental factor in its bendability. Thinner materials are generally easier to bend without cracking or breaking, while thicker materials may require specialized equipment to achieve the same results.

Grain Structure: The way aluminum is processed can result in different grain structures, which can either enhance or hinder its ability to bend. Materials with a finer grain structure generally exhibit better ductility and can bend more easily without failure.

Surface Condition: The surface treatment of aluminum can influence its bendability by affecting friction and the presence of defects. A rough or oxidized surface may create challenges during bending, while smoother finishes can facilitate better results.

How Do Thickness and Bend Radius Influence Bending Performance?

Bend Radius: The bend radius is crucial because a smaller bend radius requires the material to stretch more, which can lead to issues such as cracking or warping, especially in thicker materials. A larger bend radius is more forgiving and helps to maintain the material’s integrity, making it ideal for applications where aesthetics and structural strength are both important. The appropriate bend radius depends on the thickness of the aluminum and the specific alloy being used.

Material Properties: Aluminum alloys vary in their composition and treatment, which affects their ductility, strength, and weldability. For example, alloys like 6061 and 5052 offer good bending capabilities but behave differently when subjected to bending and welding processes. Understanding these properties can help in selecting the best aluminum for specific bending and welding applications, ensuring optimal performance and durability.

What Role Does Percent Elongation Play in Bendability?

Percent elongation is a crucial factor that determines the bendability of aluminum alloys.

- Definition of Percent Elongation: Percent elongation is a measure of the ductility of a material, defined as the percentage increase in length that a material can undergo before failure.

- Influence on Bendability: Higher percent elongation indicates that a material can deform more before breaking, which is essential for bending processes.

- Comparison of Alloys: Different aluminum alloys exhibit varying levels of percent elongation, influencing their suitability for bending and welding applications.

- Heat Treatment Effects: Heat treatment processes can enhance or reduce percent elongation, thereby affecting the material’s bendability in specific applications.

- Practical Applications: Understanding percent elongation helps in selecting the right aluminum alloy for projects requiring significant bending without cracking.

Percent elongation is a measure of the ductility of a material, defined as the percentage increase in length that a material can undergo before failure. It reflects how much a material can stretch and deform without breaking, which is vital when bending aluminum for various applications.

Higher percent elongation indicates that a material can deform more before breaking, which is essential for bending processes. A material with high ductility can be bent into tight radii without fracturing, making it more suitable for intricate designs and applications.

Different aluminum alloys exhibit varying levels of percent elongation, influencing their suitability for bending and welding applications. For instance, alloys like 6061 have good elongation properties, making them ideal for forming processes, while others might be more brittle and less suitable for bending.

Heat treatment processes can enhance or reduce percent elongation, thereby affecting the material’s bendability in specific applications. For example, certain heat treatments can improve ductility in some alloys, making them easier to work with during fabrication.

Understanding percent elongation helps in selecting the right aluminum alloy for projects requiring significant bending without cracking. Engineers and fabricators can use this knowledge to ensure that the chosen material will meet the physical demands of the intended application.

Which Aluminum Alloys Are Best Suited for Bending?

The best aluminum alloys for bending and welding are typically those that offer a good balance of formability and strength.

- 5052 Aluminum: This alloy is known for its excellent corrosion resistance and good weldability, making it suitable for marine environments and automotive applications. Its moderate strength and high ductility allow it to bend easily without cracking, making it a popular choice for complex shapes.

- 6061 Aluminum: Frequently used in structural applications, 6061 offers good mechanical properties and weldability. While it is stronger than 5052, it also has good formability, allowing it to be bent and welded with relative ease, making it ideal for frames and supports.

- 3003 Aluminum: This alloy is known for its excellent workability and good corrosion resistance, making it easy to bend and shape. While it has lower strength compared to other alloys, its high ductility allows it to be formed into complex shapes without significant risk of cracking.

- 7075 Aluminum: While primarily known for its high strength, 7075 can be challenging to weld due to its susceptibility to cracking. However, it is still a viable option for bending when heat-treated, as it maintains its integrity and shape under stress, making it ideal for aerospace applications.

- Alclad Aluminum: This type of aluminum features a thin layer of pure aluminum over a core alloy, providing excellent corrosion resistance and good welding properties. The cladding allows for easier bending while retaining strength, making it suitable for applications in harsh environments.

Why Is Aluminum Alloy 3003 Highly Recommended for Bending?

This happens because Aluminum Alloy 3003 possesses a combination of excellent ductility, good workability, and moderate strength, making it particularly suitable for bending processes.

According to the Aluminum Association, Alloy 3003 is known for its high corrosion resistance and formability, which contributes to its effectiveness in applications requiring bending and welding (Aluminum Association, 2021). This alloy contains manganese as its principal alloying element, which enhances its ability to be shaped without cracking or breaking.

The underlying mechanism that makes Alloy 3003 so effective for bending is its microstructure. The fine grain structure allows for plastic deformation under stress without significant hardening, which is critical during bending operations. When subjected to bending forces, the material can accommodate the changes in shape without fracturing, unlike higher-strength alloys that may become too brittle. Additionally, the presence of manganese in the alloy contributes to its durability and resistance to work hardening, allowing for repeated bending without failure. As a result, Alloy 3003 is often used in applications such as HVAC components, decorative trim, and cooking utensils where bending and welding are necessary.

How Does Aluminum Alloy 5052 Compare in Bendability?

| Aspect | Aluminum Alloy 5052 | Other Alloys |

|---|---|---|

| Bendability | Good bendability, suitable for complex shapes with minimum cracking. | Varies; some may offer better or worse bendability depending on composition. |

| Tensile Strength | Moderate tensile strength, balancing flexibility with durability. | Higher strength alloys may resist bending but are less workable. |

| Weldability | Excellent weldability, allows for strong joints without compromising bendability. | Weldability varies; some alloys may weaken at weld points. |

| Bend Radius | Minimum bend radius of 3T (three times the thickness) for effective bending. | Varies; some alloys may require larger bend radii due to increased strength. |

| Cost-effectiveness | Generally cost-effective for both bending and welding applications. | Cost varies widely; some high-strength alloys may be more expensive. |

| Common Applications | Used in marine environments, automotive components, and pressure vessels. | Applications depend on specific alloy properties; may include aerospace and structural components. |

What Makes Aluminum Alloy 6061 a Popular Choice for Bending?

Aluminum Alloy 6061 is a favored choice for bending and welding due to its unique properties and versatility.

- Good Workability: Aluminum 6061 offers excellent workability, which makes it easy to bend and shape without cracking. This is crucial for applications that require intricate designs or precise angles.

- Weldability: The alloy has good weldability, allowing it to be easily joined using various welding techniques. This property is vital for projects that demand both bending and welding, ensuring strong and durable connections.

- Strength-to-Weight Ratio: Aluminum 6061 provides a high strength-to-weight ratio, making it strong yet lightweight. This characteristic is particularly beneficial in applications where weight savings are important, such as in aerospace and automotive industries.

- Corrosion Resistance: This alloy exhibits excellent corrosion resistance, which extends its life in harsh environments. The durability against oxidation and other corrosive elements ensures that bent or welded components maintain their integrity over time.

- Versatility: Aluminum 6061 can be used in various forms, including sheets, plates, and extrusions. This versatility allows for a wide range of applications, from structural components to decorative elements, while maintaining ease of bending and welding.

What Are the Most Effective Aluminum Alloys for Welding?

The most effective aluminum alloys for welding are:

- 6061: A versatile aluminum alloy, 6061 is known for its excellent weldability and corrosion resistance. It is commonly used in structural applications, automotive parts, and marine components due to its good mechanical properties and ability to take on various forms.

- 4047: This alloy is primarily used for welding applications because of its high silicon content, which enhances fluidity and reduces the risk of cracking during the welding process. Its self-fluxing characteristics make it ideal for brazing and welding thin materials.

- 5356: Often used as a filler material in welding applications, 5356 is known for its high strength and corrosion resistance, particularly in marine environments. It is commonly used for welding stainless steel and in applications that require high ductility and toughness.

- 7075: While not as easily weldable as other alloys, 7075 can be welded with special techniques and fillers. It is prized for its high strength-to-weight ratio, making it ideal for aerospace and high-stress applications, though care must be taken to manage its heat treatment process during welding.

- 3003: This alloy is known for its excellent workability and moderate strength, making it a popular choice for forming and bending. While it can be welded, it is often used in applications where the welds are not exposed to high-stress conditions, such as in cooking utensils and storage tanks.

How Does Aluminum Alloy 4047 Enhance Welding Performance?

Aluminum Alloy 4047 is known for its excellent welding performance and is often considered one of the best aluminum grades for bending and welding.

- High Silicon Content: Aluminum Alloy 4047 contains a high silicon content, typically around 12-13%, which enhances its fluidity during welding. This allows for smoother welds and reduces the occurrence of defects such as porosity and cracking.

- Improved Corrosion Resistance: The alloy’s composition provides better resistance to corrosion compared to other aluminum alloys. This characteristic is crucial in applications exposed to harsh environments, ensuring longevity and reliability of welded joints.

- Lower Melting Point: With a lower melting point due to its silicon content, Alloy 4047 can be welded at lower temperatures, reducing the thermal stress on the material. This property minimizes warping and distortion during the welding process, which is essential for maintaining the integrity of complex shapes.

- Excellent Fillers for Welding: The alloy is often used as a filler material in welding applications, providing strong and compatible joints when combined with other aluminum alloys. Its compatibility with other aluminum types allows for versatility in various welding scenarios, enhancing overall performance.

- Good Ductility: Alloy 4047 maintains good ductility, which is vital for applications requiring bending after welding. This property allows the material to absorb stress without cracking, making it suitable for dynamic environments where flexibility is needed.

Why Is Aluminum Alloy 6061 Frequently Selected for Welding Applications?

Aluminum Alloy 6061 is frequently selected for welding applications due to its excellent mechanical properties, good corrosion resistance, and versatility, making it one of the best aluminum alloys for bending and welding.

According to the Aluminum Association, Alloy 6061 is known for its weldability and is commonly used in structural applications, including bridges and buildings, due to its strength-to-weight ratio and ability to be easily formed and welded. The American Welding Society also highlights that this alloy can be effectively welded using various methods, including MIG and TIG welding.

The underlying mechanism behind the popularity of Alloy 6061 in welding applications is its composition, which includes silicon and magnesium as its primary alloying elements. This combination enhances its weldability while maintaining strength. Additionally, the heat treatment process it undergoes allows for improved mechanical properties, which ensures that welded joints retain significant strength. The alloy’s thermal conductivity also aids in efficient heat dissipation during the welding process, minimizing warping or distortion.

Furthermore, the corrosion resistance of Alloy 6061 is attributed to the formation of a protective oxide layer on its surface, which prevents oxidation and degradation over time. This property is particularly important in applications exposed to harsh environments. The balance of strength, weight, and ease of fabrication makes Alloy 6061 a preferred choice for engineers and manufacturers looking for the best aluminum for bending and welding applications.

What Techniques Can Improve Bending and Welding of Aluminum?

Several techniques can enhance the bending and welding of aluminum effectively:

- Proper Alloy Selection: Choosing the right aluminum alloy is crucial as some alloys are more conducive to bending and welding than others. For example, 6061 and 5052 alloys are popular for their excellent weldability and formability, making them ideal for various applications.

- Preheating: Preheating aluminum before bending or welding can significantly reduce the risk of cracking and improve the material’s ductility. This technique helps to alleviate residual stresses in the metal, allowing for smoother bends and more reliable welds.

- Use of Jigs and Fixtures: Employing jigs and fixtures during the bending process ensures consistent angles and shapes, leading to more precise outcomes. These tools help minimize movement of the material, allowing for better control during welding and reducing the chances of warping.

- Controlled Cooling: Managing the cooling rate after welding is important to prevent distortions and improve the mechanical properties of the weld. Gradual cooling allows the aluminum to relieve internal stresses, leading to stronger and more durable joints.

- Welding Techniques: Utilizing appropriate welding techniques, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas), is essential for achieving high-quality welds. These methods allow for better control over the heat input and the welding pool, resulting in cleaner, stronger joints in aluminum.

- Surface Preparation: Properly preparing the surface of aluminum before bending or welding is vital for achieving strong bonds. This includes cleaning the metal to remove any oxidation, oil, or dirt, ensuring that welds adhere properly and that bends are smooth.

- Use of Lubricants: Applying lubricants during the bending process can reduce friction, making it easier to form the aluminum without causing damage. This technique can also enhance the lifespan of tools used in the bending process by minimizing wear.