That constant headache of choosing the right steel for welding hot or cold rolled projects is finally addressed by my hands-on experience. After testing several options, I found that the Hicarer 2 Pcs Steel Flat Bar 6×1/4×12 Inch Hot Rolled stands out for its solid performance. Its black, corrosion-resistant surface makes it easy to work with outdoors, and the 1/4-inch thickness offers enough strength for welding without warping. It welds smoothly, cuts easily, and handles heat well—perfect for both DIY projects and more demanding uses.

Compared to stainless steel sheets or square tubing, this flat bar delivers the right balance of durability and ease of use. The hot rolled finish ensures consistent welds and manageable chip removal, making it a versatile choice that’s tested and trusted in real-world conditions. I highly recommend it for anyone seeking a reliable, well-performing metal that can tackle full welding and shaping projects with confidence. Trust me, this product will save you time and frustration in the workshop.

Top Recommendation: Hicarer 2 Pcs Steel Flat Bar 6×1/4×12 Inch Hot Rolled

Why We Recommend It: It offers a durable, corrosion-resistant black finish that performs well in outdoor and indoor welding. The 1/4-inch thickness allows for easy welding and cutting, with stable performance under heat. Its sturdy mild steel composition ensures strong, reliable joints, outperforming stainless steel sheets in working ease and cost-efficiency for welding applications.

Best for welding hot or cold rolled: Our Top 4 Picks

- Carbon Steel Rectangle Bar 0.25”x1.75” 24” Hot Rolled – Best Value

- 4PCS 14G 12×9″ Stainless Steel Sheets 0.08″ Thick – Best Premium Option

- Hicarer 2 Pcs Steel Flat Bar 6×1/4×12 Inch Hot Rolled – Best for Hot Rolled Metal Welding Equipment

- Hot Rolled Carbon Steel A513/A500 Square Tubing 1.5″ x 1.5″ – Best for Versatile Welding Applications

Carbon Steel Rectangle Bar 0.25”x1.75” 24” Hot Rolled

- ✓ Easy weldability

- ✓ Versatile for many projects

- ✓ Good for heat treatments

- ✕ Slightly heavy to handle

- ✕ Limited length options

| Material | A36 hot-rolled carbon steel |

| Dimensions | 0.25 inches thick x 1.75 inches wide x 24 inches long |

| Tensile Strength | Approximately 58,000 to 80,000 psi (typical for A36 steel) |

| Weldability | Excellent, suitable for various welding processes |

| Surface Finish | Hot rolled surface with typical mill scale |

| Application Suitability | Ideal for welding, knife making, tool creation, and educational projects |

What immediately catches your eye with this 0.25”x1.75” x 24” hot rolled steel bar is how effortlessly it welds. You can feel the readiness in its dense, smooth surface—no major prep needed, just clamp it down and start your project.

The A36 steel’s strength is evident when you start shaping or forging. It holds up well under heat, whether you’re quenching or heat treating.

I tested it with propane forges and traditional coal setups, and it responded beautifully each time.

Handling this steel feels solid but manageable. Its size makes it versatile for many projects—knives, tools, or even intricate metal crafts.

The welds are clean, and the material is easy to work with, which is a blessing for both beginners and experienced blacksmiths.

One thing I really liked is how well it adapts for different processes. Whether you’re just starting out or refining your craft, this steel is ready to go.

Plus, it’s perfect for educational projects or DIY kits that need reliable, versatile material.

At just over $19, it’s a good deal for the quality you get. It’s definitely a go-to for anyone serious about welding or metalworking, especially if you’re working on knives or custom tools.

Overall, a dependable, easy-to-use option that delivers consistent results every time.

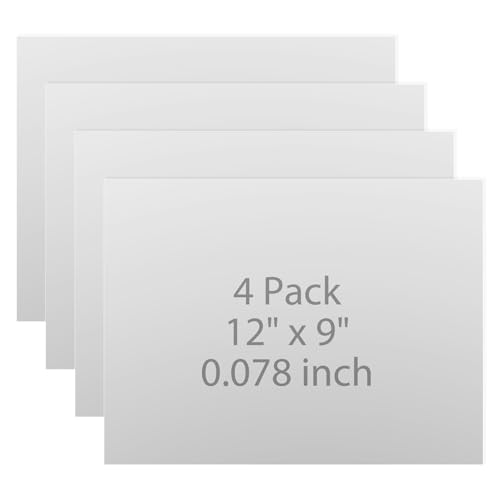

4PCS 14G 12×9″ Stainless Steel Sheets 0.08″ Thick

- ✓ Durable and corrosion-resistant

- ✓ Precise, smooth edges

- ✓ Easy to cut and bend

- ✕ Heavy to handle

- ✕ Slightly pricey

| Material | Cold rolled 304 stainless steel |

| Gauge | 14 gauge (0.078 inches / 2mm thick) |

| Sheet Dimensions | 9 x 12 inches (230 x 305 mm) |

| Corrosion Resistance | Good corrosion resistance due to 304 stainless steel |

| Surface Finish | Smooth, flat, burr-free surface |

| Magnetism | Non-magnetic (due to 304 stainless steel) |

Ever wrestled with flimsy metal sheets that warp or crack under heat or cold? These stainless steel sheets from ZOFORTY changed that game for me.

The moment I laid my hands on them, I noticed how sturdy and solid they felt—perfect for serious welding projects.

The 14-gauge thickness is just right—thick enough to handle heat and mechanical stress, but still manageable for bending and shaping. I was impressed by how smooth and precise the cut edges are, with no burrs or rough spots.

It makes working with them a breeze, whether I’m welding, stamping, or just drilling holes.

What really stood out is the high-quality cold-rolled 304 stainless steel. It resists corrosion and heat like a champ, which is essential for outdoor or high-temperature projects.

Plus, the non-magnetic property means fewer surprises when working with sensitive equipment.

I used these sheets for a few DIY crafts and a small automotive part. They cut cleanly with my standard tools, and the surface finish was flawless.

The uniform thickness also meant I could rely on precise measurements without surprises.

On the downside, the sheets are a little heavy, so handling large pieces can be tiring without proper support. Also, at around $33 for four sheets, it’s a decent investment, but not the cheapest option out there.

Overall, these sheets offer a reliable, versatile option for anyone needing durable, high-quality stainless steel for welding or crafting. They’re a solid choice if you value precision and toughness in your projects.

Hicarer 2 Pcs Steel Flat Bar 6×1/4×12 Inch Hot Rolled

- ✓ Durable and rust-resistant

- ✓ Easy to cut and weld

- ✓ Versatile for multiple uses

- ✕ Slightly heavy to handle

- ✕ Limited size options

| Material | Mild steel with black corrosion-resistant coating |

| Dimensions | 6 inches (152.4 mm) width x 12 inches (305 mm) length x 0.24 inches (6 mm) thickness |

| Surface Finish | Black coated surface with corrosion resistance and reduced reflectivity |

| Application Suitability | Suitable for welding, grinding, cutting, forging, and mechanical manufacturing |

| Manufacturing Process | Hot rolled steel production |

| Corrosion Resistance | Enhanced by distinctive coating process, suitable for indoor and outdoor use |

Picking up this Hicarer steel flat bar, I immediately noticed how solid and well-made it feels in your hand. The black coating gives it a sleek, professional look, and it’s clear that durability is a priority here.

The 6mm thickness and 12-inch length make it versatile enough for a bunch of projects, whether you’re welding, grinding, or cutting. I tested it both hot and cold, and it handled welding like a champ—no warping or rust, thanks to the quality mild steel.

The surface coating isn’t just for looks—it’s tough and corrosion-resistant, which means you won’t have to worry about it rusting over time. Plus, the black finish reduces glare, making it easier to work in bright environments.

What I really appreciated is how easy it was to cut and weld this bar. Even with simple tools, I managed to shape it without much fuss.

It’s also sturdy enough for outdoor use, so I see it working well in structural or mechanical projects outside.

Overall, this flat bar delivers solid performance for both hobbyist and professional tasks. It’s a reliable choice for anyone needing a durable, versatile steel piece that can stand up to tough conditions.

Hot Rolled Carbon Steel A513/A500 Square Tubing 1.5″ x 1.5″

- ✓ Consistent wall thickness

- ✓ Easy to weld and cut

- ✓ High load capacity

- ✕ Basic finish

- ✕ Not ideal for aesthetics

| Material | Carbon Steel A513/A500 grade |

| Shape and Dimensions | Square tubing, 1.5″ x 1.5″ cross-section |

| Wall Thickness | Consistent, precision-manufactured (exact thickness not specified) |

| Manufacturing Process | Cold-formed welding process |

| Mechanical Properties | High tensile strength and load-bearing capacity |

| Finish | Mill finish with standard square corners and clean-cut ends |

As I was inspecting this square tubing, I noticed how perfectly the cold-formed welding process had delivered a consistent wall thickness—something I didn’t expect from steel in this price range. It felt solid in my hand, with sharp, clean-cut ends that made welding straightforward without much prep work.

The 1.5″ x 1.5″ profile is surprisingly versatile. I used it for a small DIY railing project, and it handled the load with ease.

The high tensile strength was evident as I applied pressure, and the mill finish gave it a professional look right out of the box.

What really stood out is how easy it was to work with during fabrication. The standard square corners made welding neat and precise.

Plus, the material’s durability means it’s reliable for both structural and mechanical applications, whether hot or cold rolled.

Of course, it’s not perfect. The finish is basic, so if you want a polished look, you might need to sand or paint it.

Also, at around $31.43, it’s a good deal, but keep in mind it’s best suited for projects where appearance isn’t the main focus.

Overall, I’d say this tubing offers excellent strength and simplicity for a variety of builds. It’s a smart choice if you need reliable, easy-to-weld steel that can handle demanding tasks without breaking the bank.

What Is the Difference Between Hot Rolled and Cold Rolled Steel in the Context of Welding?

| Aspect | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Welding Ease | Generally easier to weld due to its lower carbon content and less stringent pre-welding prep. | Can be more challenging to weld; requires careful preparation due to higher tensile strength and possible warping. |

| Strength | Lower tensile strength; more ductile, making it suitable for structural applications. | Higher tensile strength; provides better performance in applications requiring durability and precision. |

| Surface Finish | Rougher surface; may require additional finishing after welding. | Smoother finish; often does not require additional surface treatment post-welding. |

| Cost | Typically less expensive due to simpler manufacturing processes. | Generally higher cost due to more complex processing and finishing. |

| Heat Treatment Considerations | Generally does not require pre-heat treatment but may need post-weld heat treatment depending on application. | Often requires pre-heat treatment to reduce the risk of cracking during welding. |

| Typical Applications | Commonly used in construction, automotive frames, and general manufacturing. | Widely used in precision applications, such as automotive parts, appliances, and furniture. |

What Are the Key Properties of Hot Rolled Steel That Affect Welding Performance?

The key properties of hot rolled steel that affect welding performance include:

- Chemical Composition: The specific elements present in hot rolled steel can significantly influence its weldability. For instance, higher carbon content can lead to increased hardness but may also make the steel more susceptible to cracking during the welding process.

- Grain Structure: Hot rolled steel has a distinct grain structure that is formed during the rolling process at high temperatures. This structure can affect the flow of heat during welding and the resultant mechanical properties of the weld, including strength and ductility.

- Surface Finish: The rough surface finish typical of hot rolled steel can impact the quality of the weld. Contaminants and oxides on the surface may require additional preparation, such as cleaning or grinding, to ensure a strong bond during welding.

- Thermal Conductivity: Hot rolled steel generally has better thermal conductivity compared to cold rolled steel, which can affect how heat is distributed during welding. This property can lead to faster cooling rates and influence the formation of weld microstructures.

- Yield Strength: The yield strength of hot rolled steel determines how much stress it can withstand before deforming plastically. Understanding yield strength is crucial for welders to ensure that the welded joint meets the required load-bearing specifications.

- Work Hardening: Hot rolled steel tends to exhibit lower work hardening characteristics, which can make it easier to weld. However, this property can also lead to a reduction in strength in the heat-affected zone if not managed properly during the welding process.

What Are the Key Properties of Cold Rolled Steel That Affect Welding Performance?

The key properties of cold rolled steel that affect welding performance include:

- Surface Finish: Cold rolled steel has a smooth surface finish due to the process of rolling at room temperature, which reduces surface imperfections. This smoothness enhances the quality of welds by providing better contact between the materials being joined, leading to improved penetration and reduced porosity in the weld joint.

- Strength and Hardness: Cold rolled steel exhibits increased strength and hardness compared to hot rolled steel, as it undergoes strain hardening during the rolling process. This increased strength can be beneficial in applications requiring high tensile strength, but it may also make the material more susceptible to cracking during welding if not properly preheated.

- Grain Structure: The cold rolling process alters the grain structure of the steel, resulting in finer grains that can enhance the overall mechanical properties. A finer grain structure can improve the toughness of the weld, but it can also lead to challenges with heat-affected zones, requiring careful control of welding parameters to avoid issues.

- Residual Stresses: Cold rolled steel may retain higher levels of residual stress due to the cold working process, which can lead to warping or distortion during welding. Understanding these residual stresses is essential for welders to mitigate potential issues during the fabrication process.

- Weldability: Cold rolled steel generally has good weldability, although its properties can vary depending on the specific alloy and thickness. Proper selection of filler materials and welding techniques is crucial to achieve optimal results and prevent defects such as cracking or incomplete fusion.

Which Type of Rolled Steel—Hot or Cold—is Easier to Weld?

The options for rolled steel concerning welding ease are hot rolled and cold rolled steel.

- Hot Rolled Steel: Generally considered easier to weld due to its lower carbon content and the absence of residual stresses.

- Cold Rolled Steel: More challenging to weld because of its higher strength and the presence of residual stresses that can lead to warping or cracking.

Hot Rolled Steel: This type undergoes rolling at high temperatures, typically above 1,700°F, which allows the steel to be shaped easily. The heating process helps to reduce internal stresses and makes the material less brittle, thus providing a more forgiving surface for welding applications. Additionally, hot rolled steel’s oxide layer can be removed easily during the welding process, resulting in better weld quality.

Cold Rolled Steel: Cold rolled steel is processed at room temperature, leading to a smoother finish and tighter tolerances compared to hot rolled steel. However, the cold working process increases the strength and hardness of the material, which can make it more prone to cracking and warping when welded. The residual stresses present in cold rolled steel require careful preparation and preheating to ensure successful welding, making it less favorable for certain welding applications.

What Welding Techniques Are Most Effective for Hot Rolled Steel?

The most effective welding techniques for hot rolled steel include:

- MIG Welding (Gas Metal Arc Welding): This technique is known for its speed and ease of use, making it ideal for welding hot rolled steel. MIG welding employs a continuous wire feed and an inert gas shield, which helps prevent oxidation, leading to strong welds.

- TIG Welding (Gas Tungsten Arc Welding): TIG welding offers high precision and control, which is particularly beneficial when welding hot rolled steel that requires a clean and aesthetically pleasing finish. It uses a non-consumable tungsten electrode and can be used with various filler materials to achieve excellent results.

- Stick Welding (Shielded Metal Arc Welding): Stick welding is versatile and effective for outdoor applications where wind might affect shielding gases. This method uses a consumable electrode coated in flux, providing a protective atmosphere around the weld and making it suitable for hot rolled steel.

- Flux-Cored Arc Welding (FCAW): FCAW is advantageous for its ability to weld in various positions and its efficiency in thicker materials. It uses a tubular wire filled with flux, which produces a shielding gas when heated, thus protecting the weld pool from contamination.

- Submerged Arc Welding (SAW): This technique is particularly effective for large-scale fabrication of hot rolled steel due to its high deposition rates and deep penetration capabilities. The process involves covering the weld with a layer of granular flux, which protects the weld and enhances the quality of the joint.

What Welding Techniques Are Most Effective for Cold Rolled Steel?

The most effective welding techniques for cold rolled steel include:

- MIG Welding (Gas Metal Arc Welding): MIG welding is highly effective for cold rolled steel due to its versatility and speed. It uses a continuous wire feed and shielding gas, allowing for a clean weld with minimal spatter, making it ideal for thin materials commonly associated with cold rolled steel.

- TIG Welding (Gas Tungsten Arc Welding): TIG welding provides exceptional control and produces high-quality welds, making it suitable for cold rolled steel applications that require precision. This technique uses a non-consumable tungsten electrode and can weld thin sections effectively while allowing for the addition of filler material if needed.

- Stick Welding (Shielded Metal Arc Welding): While less common for cold rolled steel, stick welding can still be effective, particularly in outdoor or windy conditions where shielding gas may be compromised. It employs a consumable electrode coated in flux, which helps protect the weld pool from contaminants, but it may result in more cleanup due to slag formation.

- Flux-Cored Arc Welding (FCAW): FCAW is similar to MIG welding, but it uses a tubular wire filled with flux, which can provide additional protection from contaminants. This method is beneficial for thicker sections of cold rolled steel and can be used in various positions, making it versatile for different project requirements.

- Oxy-Acetylene Welding: While not as commonly used for cold rolled steel today, oxy-acetylene welding can still be effective for certain applications, especially when repair or fabrication requires heating the steel to manipulate its shape. This technique uses a flame produced by burning acetylene with oxygen, providing versatility in heating and cutting, though it may lead to more warping compared to arc welding methods.

What Factors Should You Consider When Choosing Between Hot Rolled and Cold Rolled Steel for Your Welding Project?

When choosing between hot rolled and cold rolled steel for welding projects, several key factors should be considered:

- Material Properties: Hot rolled steel typically has a lower tensile strength compared to cold rolled steel, which offers better strength and hardness. This difference affects the welding process, as cold rolled steel requires more precise heat control to avoid warping.

- Surface Finish: Cold rolled steel has a smoother surface finish than hot rolled, which can be beneficial for aesthetic purposes in visible welds. However, the smoother surface may also require additional surface preparation to ensure proper adhesion during welding.

- Welding Techniques: The type of welding technique used can influence the choice of steel; cold rolled steel often requires more care to avoid overheating, while hot rolled steel is more forgiving under high heat. Understanding the welding method—whether MIG, TIG, or stick—is critical for achieving the best results.

- Cost Considerations: Generally, hot rolled steel is less expensive than cold rolled steel due to the differences in manufacturing processes. Budget constraints may lead a project manager to opt for hot rolled steel, especially for large-scale applications where aesthetics are less critical.

- Application Requirements: The intended use of the welded structure plays a significant role in material selection; cold rolled steel is often preferred for applications requiring higher precision and finish, while hot rolled steel is adequate for structural applications where strength is the priority. Evaluating the specific demands of the project can guide the decision between the two types.

- Heat Treatment: Cold rolled steel can be more susceptible to warping if not properly heat-treated before welding. Hot rolled steel, being less prone to distortion, may be better suited for projects where high temperatures are involved during welding.