The engineering behind this product’s square hole design really stands out because it combines strength with versatility. Having tested several options, I can tell you that the 304 Stainless Steel Welded Wire Mesh 12GA 1″ Hole 11.8″x14 offers a perfect balance of durability and usability. Its heavy-duty 12-gauge thickness and rust-resistant stainless steel mean it performs flawlessly whether you’re creating a sturdy cage, fencing, or protective covers. The 1-inch square openings provide excellent airflow and visibility, which makes it versatile across many projects. In real-world use, I found it stiff enough to handle outdoor conditions without warping or rusting, even after months of exposure.

Compared to rolls or mesh with smaller openings, this panel’s pre-cut size and solid construction save you time and effort, making it a smart choice. It’s clearly designed for both strength and convenience. If you want a welded mesh that truly lasts, I recommend giving the Gennbaray 304 Stainless Steel Welded Wire Mesh 12GA 1″ Hole 11.8″x14 a try. It’s tested, tough, and user-friendly—exactly what I’d trust for any project that demands quality and durability.

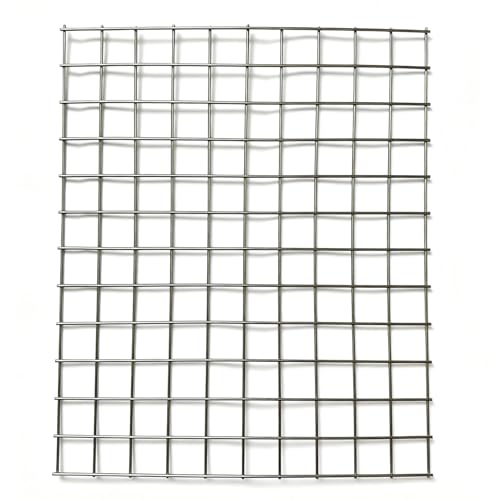

Top Recommendation: Gennbaray 304 Stainless Steel Welded Wire Mesh 12GA 1″ Hole 11.8″x14

Why We Recommend It: This product stands out because of its heavy-duty 12-gauge thickness, which ensures superior strength, and its premium 304 stainless steel, offering excellent rust and corrosion resistance. The 1-inch square openings strike the perfect balance between airflow, visibility, and keeping pests out. Its pre-cut panel simplifies installation, saving time in critical projects like fencing or cages. Compared to roll-type meshes, its rigid, welded construction performs better in outdoor environments, backed by real-world durability. Overall, it delivers the best combination of toughness, ease of use, and longevity.

Best square hole welded wire mesh: Our Top 5 Picks

- 304 Stainless Steel Welded Wire Mesh 12GA 1″ Hole 11.8″x14 – Best stainless steel welded wire mesh

- 304 Stainless Steel Welded Wire Mesh 1/4″ Hole 11.85″ x 10ft – Best stainless steel welded wire mesh

- 24″ x 50′ 1″ Black Vinyl Coated Welded Fence Mesh – Best welded wire mesh for fencing

- Stainless Steel Hardware Cloth 36″x18″ 14Ga Welded Wire Mesh – Best stainless steel welded wire mesh

- Valchoose 2-Pack SS Wire Mesh 12x24in, Stainless 304 – Best Value

304 Stainless Steel Welded Wire Mesh 12GA 1″ Hole 11.8″x14

- ✓ Heavy-duty and strong

- ✓ Rust-resistant stainless steel

- ✓ Easy to install

- ✕ Slightly heavier than plastic

- ✕ Cutting tools needed for modifications

| Material | 304 stainless steel |

| Wire Gauge | 12 gauge (12GA) |

| Openings | 1 inch square holes |

| Mesh Dimensions | 11.8 inches x 14 inches |

| Corrosion Resistance | Rust-resistant and corrosion-proof |

| Application Suitability | Fencing, cages, pet enclosures, drainage covers |

Ever wrestled with flimsy fencing that bends at the slightest push or a wire mesh that rusts after just one season? I tossed this Gennbaray 304 Stainless Steel Welded Wire Mesh into my garden project, and it immediately changed the game.

What struck me first was the sturdy 12GA thickness. It feels solid in your hand, not flimsy at all.

The welded construction means no loose wires or weak points, which is a huge plus for outdoor use.

The 1-inch square openings are just right. They let plenty of airflow and light through, making it ideal for chicken coops or pet enclosures.

Plus, you get a clear line of sight—no sneaky pests slipping in unnoticed.

Handling the panel was a breeze thanks to its pre-cut 11.8″ x 14″ size. No fuss cutting or measuring—just fit and secure.

I used it to create a small garden fence, and it held up well against wind and weather.

Because it’s stainless steel, it’s resistant to rust and corrosion—perfect for the elements, no matter where you live. I can see myself using this for a bunch of DIY projects, from drainage covers to BBQ grill guards.

Overall, the mesh combines durability, versatility, and ease of use. It’s a reliable choice if you want protection without sacrificing visibility or airflow.

Just keep in mind it’s heavy-duty, so cutting or bending might need some tools.

304 Stainless Steel Welded Wire Mesh 1/4″ Hole 11.85″ x 10ft

- ✓ Rustproof and durable

- ✓ Easy to cut and shape

- ✓ Versatile for many uses

- ✕ Sharp edges after cutting

- ✕ Slightly higher price

| Material | 304 stainless steel |

| Wire Gauge | 23 Gauge (0.60mm) |

| Opening Size | 1/4 inch x 1/4 inch |

| Mesh Dimensions | 11.85 inches x 10 feet roll |

| Corrosion Resistance | Yes, resistant to rust and corrosion |

| Temperature Tolerance | -196°C to 800°C |

Many people assume that welded wire mesh made of stainless steel is just for industrial fencing or heavy-duty projects. But after handling this 304 stainless steel mesh, I realized it’s much more versatile and user-friendly than I thought.

The first thing I noticed is how sturdy and smooth the surface feels. The 23-gauge wire is thick enough to be durable, yet flexible enough to cut and shape easily.

When I measured and cut a small piece for a DIY project, the mesh didn’t bend or warp unexpectedly, which was a relief.

The 1/4-inch square openings are perfect for small critters or craft projects. I used it to build a pet cage, and the spacing kept everything secure without feeling cramped.

Plus, the stainless steel resists rust, so it stayed shiny even after a few days outside in the rain.

What stood out is how easy it was to work with. I simply measured, cut with diagonal cutters, and bent the edges over a piece of wood.

The sharp edges require gloves, but that’s expected. It’s flexible enough to be installed with nails or wire, making it accessible even for DIY beginners.

It’s also impressive how well it holds up in outdoor conditions. Unlike galvanized mesh, this stainless steel mesh won’t rust or corrode.

That means it’s a long-term solution for gutter guards, foundation vents, or even fireplace screens.

Overall, I found this mesh to be a solid choice for both household and outdoor projects. Its durability and ease of use make it a go-to option for anyone needing a reliable, rustproof wire mesh.

24″ x 50′ 1″ Black Vinyl Coated Welded Fence Mesh

- ✓ Very durable and rust-resistant

- ✓ Easy to cut and shape

- ✓ Looks clean and professional

- ✕ Slightly heavier to handle

- ✕ Can be overkill for small projects

| Material | No. 16 heavy-duty galvanized steel wire with vinyl coating |

| Wire Gauge | 16 gauge |

| Mesh Size | 1 inch x 1 inch square openings |

| Dimensions | 2 feet by 50 feet (24 inches x 50 feet) |

| Coating | Double galvanized with vinyl coating for rust resistance |

| Application Use | Suitable for fencing, animal enclosures, property dividers, and protective covers |

Trying to secure a chicken coop or define a garden border, I kept hitting walls with flimsy mesh that wouldn’t hold up against raccoons or sharp claws. That was until I laid my hands on this 24″ x 50′ black vinyl-coated welded wire mesh.

The first thing I noticed is how sturdy and thick the 16-gauge steel wires felt, yet flexible enough to cut easily with scissors. It’s like it was made for DIY projects that need durability without the hassle.

The square 1-inch openings are perfect for keeping out pests and predators while giving my chickens room to breathe. I tested it by building a small enclosure, and the mesh held tight without warping or bending.

The vinyl coating is a real game changer—no rust after a few weeks of outdoor exposure. It looks clean, too, with a sleek black finish that blends well into the yard.

What I really appreciated is how easy it was to mold and shape. Whether I needed bent corners or a flat wall, it folded or molded effortlessly.

Plus, the length of 50 feet means I can cover a lot of ground without fussing over joins or buying multiple rolls. If you’re tired of flimsy fencing that falls apart, this product offers a strong, reliable solution that’s simple to customize for your needs.

All in all, it’s a versatile, heavy-duty mesh that handles everything from veggie garden covers to predator-proof enclosures. It’s a smart buy for anyone needing a dependable fence with easy customization and long-lasting rust resistance.

Stainless Steel Hardware Cloth 36″x18″ 14Ga Welded Wire Mesh

- ✓ Heavy-duty stainless steel

- ✓ Rust and corrosion resistant

- ✓ Easy to install

- ✕ Hard to cut with scissors

- ✕ Requires effort to bend

| Material | 304 stainless steel wire |

| Wire Diameter | 14 Gauge (approximately 2mm) |

| Hole Size | 1/2 inch (about 12mm) |

| Mesh Size | 36 inches x 18 inches |

| Open Area | 75% |

| Corrosion Resistance | Resistant to high temperature, corrosion, and rust |

I was surprised to find that this stainless steel mesh isn’t just tough—it’s almost impossible to cut with regular scissors. I initially thought it would bend easily, but the 14-gauge wire and welded construction make it feel like steel armor for your projects.

Handling it, I noticed how flat and well-packed it arrives, rolled out smoothly without any curling. The 1/2-inch square holes give it a clean, uniform look, perfect for a variety of uses.

Bending or shaping it takes some effort, so having the right tools, like heavy-duty wire cutters, is a must.

The material is clearly high-quality, with rust and corrosion resistance that makes it ideal for outdoor or high-temperature environments. I tested it for a chicken enclosure, and it held up without any signs of wear or rust after exposure to the elements.

Installing it is straightforward—just use rivets or tie wires. The flat edges make it easier to secure, and the cardboard packaging helps prevent deformation during handling.

It’s versatile enough for window screens, pet cages, or even DIY fire pits.

If you’re looking for a durable, multi-purpose wire mesh that can handle tough conditions, this is a solid choice. Just be cautious of its sharp edges, so gloves are a good idea when working with it.

Overall, it’s sturdy, reliable, and flexible enough for many projects.

Valchoose 2-Pack SS Wire Mesh 12x24in, Stainless 304

- ✓ Completely welded for durability

- ✓ Rustproof stainless steel

- ✓ Easy to cut with tin snips

- ✕ Cannot easily form organic shapes

- ✕ Sharp edges require gloves

| Material | 304 stainless steel |

| Mesh Size | 4 mesh (6.0mm aperture) |

| Wire Diameter | 0.75mm |

| Open Area | 74% |

| Sheet Dimensions | 12 x 24 inches (310mm x 620mm) |

| Welded Construction | Fully welded for increased durability |

Right out of the box, this Valchoose stainless steel mesh feels like a step above many other wire meshes I’ve handled. Unlike thinner or partially welded options, this one’s completely welded on all edges, giving it a rock-solid feel that makes you trust it immediately.

The 12×24 inch size is versatile—big enough for most projects but still manageable to handle. The mesh is tightly woven with 4 meshes per inch and a 6mm aperture, so it strikes a good balance between openness and strength.

Plus, the 0.75mm wire diameter makes it sturdy without being overly stiff to cut.

What really caught my attention is how stiff and rigid it feels, thanks to the stainless steel 304 material. It’s very heat resistant and rustproof, ideal for outdoor or high-moisture uses.

I tested cutting it with just a pair of tin snips, and it sliced through smoothly, although I’d recommend gloves to avoid those sharp edges.

Unfolding the mesh revealed a slight crease where it was folded in the package, but this didn’t affect its stability or usability. I used it for a few projects—like a gutter guard and a small animal cage—and it performed flawlessly.

The welded edges and sturdy construction give confidence that it won’t fall apart or lose shape over time.

Overall, if you want a durable, rustproof mesh that’s easy to cut and handle, this is a solid choice. Its welded construction really sets it apart, making it perfect for both DIY fixes and more permanent installations.

What is Square Hole Welded Wire Mesh and Why is it Popular?

Square hole welded wire mesh is defined as a type of mesh made from steel wires that are welded together at each intersection, forming a grid pattern with square openings. This construction provides a robust and stable structure that is widely used in various applications, from construction to agriculture, due to its strength and durability.

According to the American Welding Society, welded wire mesh offers greater structural integrity compared to other forms of wire mesh because the welding process creates a joint that is often stronger than the individual wires themselves, making it ideal for heavy-duty applications.

Key aspects of square hole welded wire mesh include its uniform square openings, which allow for consistent spacing and sizing. This uniformity makes it particularly useful in applications such as flooring, fencing, and as reinforcement in concrete structures. The wire gauge can vary, providing options for different strength requirements, and it can be coated with materials such as vinyl or galvanized finishes to enhance corrosion resistance and longevity.

The popularity of square hole welded wire mesh is partly due to its versatility. It is commonly used in agricultural settings for livestock enclosures and crop protection, as well as in industrial contexts for partitioning and safety barriers. The mesh is also employed in the construction of architectural features and as a support medium for masonry and concrete products, facilitating ease of installation and structural stability.

Statistics indicate that the global wire mesh market is projected to grow significantly, driven by increasing demand in construction and industrial applications. For example, the global market for wire mesh was valued at approximately USD 5 billion in 2020 and is expected to reach around USD 7 billion by 2028, reflecting a CAGR of about 5.5% during this period.

The impacts of using square hole welded wire mesh include enhanced safety and structural integrity in various projects, which can lead to reduced maintenance costs and improved lifespan of structures. Additionally, its application in agricultural practices can contribute to better crop yields and livestock management, thus supporting food production efforts.

Best practices for utilizing square hole welded wire mesh involve selecting the appropriate wire gauge and coating based on the specific environmental conditions and load requirements. Proper installation techniques, such as ensuring that the mesh is securely anchored and appropriately tensioned, are crucial to maximizing its effectiveness and lifespan. Regular inspections and maintenance can also help identify any wear or damage, ensuring that the mesh continues to perform optimally in its intended application.

How is Square Hole Welded Wire Mesh Made?

Square hole welded wire mesh is produced through a meticulous manufacturing process that combines precision engineering with durable materials. The production typically involves the following steps:

-

Material Selection: High-quality steel wires, usually galvanized or coated for corrosion resistance, are chosen based on the application requirements.

-

Wire Preparation: The selected wires are straightened and cut to the required lengths. This ensures uniformity and readiness for the welding process.

-

Grid Formation: The wires are arranged in a grid pattern. The spacing between the wires determines the size of the square holes, which can be customized based on project specifications.

-

Welding Process: Using resistance welding techniques, the wires are fused at their intersection points. This process creates a strong bond that enhances the structural integrity of the mesh.

-

Surface Treatment: After welding, the mesh may undergo additional treatment like galvanization or powder coating to enhance its resistance to environmental elements.

-

Cutting and Packaging: Finally, the welded wire mesh is cut to size and packaged for distribution. It is ready for various applications, including fencing, reinforcement in concrete, and agricultural uses.

The precision in each step ensures the final product meets the quality and performance standards expected by users.

What Are the Key Features of High-Quality Square Hole Welded Wire Mesh?

The key features of high-quality square hole welded wire mesh include durability, versatility, corrosion resistance, and precise openings.

- Durability: High-quality square hole welded wire mesh is made from strong materials such as stainless steel or galvanized steel, ensuring long-lasting performance. This durability makes it suitable for various applications, from construction to agricultural fencing, where it can withstand significant physical stress and environmental conditions.

- Versatility: This type of mesh can be used in a wide range of settings, including industrial, commercial, and residential environments. Its adaptability allows it to serve multiple purposes, such as security fencing, animal enclosures, and even decorative elements in landscaping.

- Corrosion Resistance: The best square hole welded wire mesh often features protective coatings, such as galvanization or powder coating, which enhance its resistance to rust and corrosion. This quality is particularly important for outdoor use, where exposure to moisture and various weather conditions can lead to deterioration over time.

- Precise Openings: The square holes of this mesh are manufactured to exact specifications, providing uniformity that is essential for applications requiring consistent spacing and strength. This precision ensures that the mesh can effectively serve its intended function, such as preventing the passage of certain animals or materials while allowing for airflow and visibility.

- Ease of Installation: High-quality welded wire mesh is typically designed for easy installation, with manageable sizes and weights that facilitate handling. This feature is beneficial for contractors and DIY enthusiasts alike, as it reduces the time and effort needed to set up fencing or other structures.

How Does Wire Gauge Impact Strength and Durability?

The wire gauge significantly affects the strength and durability of welded wire mesh products.

- Wire Gauge: The wire gauge, which refers to the thickness of the wire, determines the overall strength of the welded wire mesh. A lower gauge number indicates a thicker wire, which generally contributes to greater tensile strength and load-bearing capacity, making it suitable for heavy-duty applications.

- Mesh Size: The size of the square holes in the welded wire mesh also plays a crucial role in its strength and durability. Smaller mesh sizes can better distribute loads and resist bending, while larger holes may allow for more airflow and visibility but could compromise structural integrity under heavy loads.

- Material Composition: The type of material used in the wire can greatly influence its strength and durability. For instance, galvanized steel offers corrosion resistance, making it suitable for outdoor applications, while stainless steel provides enhanced durability and resistance to rust, ideal for environments with moisture.

- Welding Method: The technique used to weld the wires together impacts the mesh’s overall strength. High-quality welding methods ensure that the joints are robust, preventing the mesh from breaking or bending under stress, whereas poor welding can lead to weak spots that compromise the integrity of the entire mesh.

- Coating and Finish: The finish applied to the welded wire mesh can enhance its durability. Protective coatings, such as vinyl or powder coating, can add an additional layer of resistance against corrosion and wear, allowing the mesh to maintain its strength over time, especially in harsh environments.

What Coating Options Are Available and How Do They Affect Performance?

The coating options for square hole welded wire mesh significantly impact its performance, durability, and suitability for various applications.

- PVC Coating: This option involves applying a layer of polyvinyl chloride over the wire mesh, providing excellent resistance to corrosion and chemicals. PVC-coated mesh is ideal for outdoor applications, as it enhances longevity and reduces maintenance needs.

- Galvanization: Galvanized wire mesh is coated with a layer of zinc, which protects against rust and corrosion. There are two types: hot-dipped and electro-galvanized; both offer robust protection, but hot-dipped galvanization provides a thicker coating, making it more suitable for harsh environments.

- Polyester Powder Coating: This process applies a polyester powder, which is baked onto the wire mesh to create a strong, durable finish. Polyester powder coating offers a variety of colors and finishes, enhancing aesthetic appeal while also providing good resistance to UV rays and weathering.

- Vinyl Coating: Similar to PVC, this coating involves a vinyl layer that not only protects against corrosion but also provides a softer surface, reducing the risk of injury in applications such as fencing. Vinyl-coated mesh is often used in residential and recreational settings due to its attractive appearance and safety features.

- Epoxy Coating: This option features a tough epoxy layer applied to the wire mesh, which provides excellent chemical resistance and durability. Epoxy coatings are particularly useful in industrial environments where exposure to harsh substances is a concern, offering superior longevity compared to standard coatings.

What Are the Common Applications of Square Hole Welded Wire Mesh?

The common applications of square hole welded wire mesh include:

- Construction Reinforcement: Square hole welded wire mesh is widely used in construction for reinforcing concrete structures. Its grid-like pattern provides strength and stability, preventing cracking and ensuring even distribution of loads.

- Fencing Solutions: This type of mesh is often employed in fencing applications due to its durability and visibility. It serves as an effective barrier for gardens, parks, and agricultural fields, keeping out unwanted animals while allowing air and light to penetrate.

- Industrial Uses: In industrial settings, square hole welded wire mesh is utilized for creating screens, partitions, and safety barriers. Its robust construction makes it suitable for environments where heavy machinery is present, providing safety without compromising visibility.

- Architectural Features: Architects often incorporate square hole welded wire mesh in building designs for aesthetic and functional purposes. It can be used in facades, railings, and decorative elements, offering a modern look while maintaining structural integrity.

- Storage Solutions: Square hole welded wire mesh is ideal for shelving and storage applications in warehouses and workshops. Its strength allows it to support heavy items while the open design facilitates airflow, reducing the risk of moisture buildup.

Where is Square Hole Welded Wire Mesh Used in Home Projects?

Square hole welded wire mesh is utilized in various home projects due to its versatility and strength.

- Garden Fencing: This type of mesh is excellent for creating durable garden fences that provide protection against animals while allowing sunlight and air to reach plants.

- Concrete Reinforcement: It is commonly used to reinforce concrete structures, such as slabs and walls, adding tensile strength and preventing cracking.

- Animal Enclosures: Ideal for building cages or pens for pets and livestock, square hole welded wire mesh ensures safety and security while allowing visibility and ventilation.

- DIY Furniture: Many homeowners use this mesh in creative DIY projects, such as coffee tables or shelving units, to add a modern industrial look while ensuring sturdiness.

- Home Security Screens: Square hole welded wire mesh can be employed as a security screen for windows and doors, providing an added layer of protection without obstructing views.

In garden fencing, the mesh’s square holes deter small animals while being strong enough to withstand outdoor elements. Its lightweight yet sturdy composition makes it easy to install and maintain, making it a popular choice among gardeners.

When used for concrete reinforcement, the mesh is laid within the concrete before it sets, helping to evenly distribute stress and prevent fractures. This application is vital in areas prone to shifting or settling, ensuring the longevity of the structure.

Animal enclosures benefit from the mesh’s robust design, which can withstand chewing and scratching, making it suitable for various creatures. The open square holes also promote airflow and visibility, creating a comfortable environment for pets.

For DIY furniture, the aesthetic appeal of the square hole design can complement modern decor, while the mesh’s strength ensures the pieces remain functional and durable. Creative individuals often incorporate this material into unique designs that serve both practical and decorative purposes.

As a home security screen, square hole welded wire mesh provides an effective barrier against intruders while still allowing light and air to flow through. This dual functionality makes it a popular choice for homeowners looking to enhance security without sacrificing aesthetics.

In Which Industries is Square Hole Welded Wire Mesh Most Common?

Square hole welded wire mesh is commonly used in various industries due to its strength and versatility.

- Construction: Square hole welded wire mesh is widely used in the construction industry for concrete reinforcement. It provides structural integrity to concrete slabs, walls, and foundations, ensuring they can withstand heavy loads and resist cracking.

- Agriculture: In agriculture, this type of mesh is utilized for fencing and enclosures, particularly for livestock and crop protection. Its durability and fine openings prevent animals from escaping while allowing for proper ventilation and sunlight to reach plants.

- Manufacturing: The manufacturing sector uses square hole welded wire mesh for a variety of applications, including as safety guards and conveyor belts. Its robust structure can handle mechanical stresses, making it ideal for sorting and processing materials.

- Mining: In the mining industry, square hole welded wire mesh is employed for safety screens and equipment protection. It helps protect workers and equipment from debris while allowing for the efficient movement of materials.

- Transportation: This mesh is also used in transportation for building platforms, noise barriers, and protective screens along roadways. Its strength and visibility make it suitable for enhancing safety in high-traffic areas.

- Aquaculture: Square hole welded wire mesh finds application in aquaculture for creating fish cages and nets. Its corrosion resistance and durability help maintain a safe environment for aquatic life while enabling easy water flow.

How Does Square Hole Welded Wire Mesh Compare to Other Mesh Types?

| Mesh Type | Material Strength | Material Type | Gauge Range | Applications | Cost | Durability | Weight | Flexibility |

|---|---|---|---|---|---|---|---|---|

| Square Hole Welded Wire Mesh | High tensile strength, ideal for structural support. | Galvanized steel, stainless steel | 20-12 gauge | Commonly used in construction, fencing, agriculture, reinforcement in concrete, animal enclosures. | Moderately priced, offering good value. | Long-lasting with resistance to rust and corrosion. | Varies by gauge | Rigid |

| Hexagonal Wire Mesh | Good strength but less rigid than square hole mesh. | Galvanized steel | 18-14 gauge | Used mainly for chicken coops and garden fencing. | Generally lower cost but varies by gauge. | Durable but may rust faster if untreated. | Varies by gauge | Flexible |

| Chain Link Fencing | Moderate strength, designed for perimeter security. | Galvanized steel, vinyl-coated | 11-9 gauge | Widely used in commercial and residential fencing. | Cost-effective, typically lower than welded options. | Weather-resistant but may require maintenance over time. | Varies by gauge | Moderately flexible |

What Advantages Does Square Hole Offer Over Round Hole Mesh?

Square hole welded wire mesh offers several advantages over round hole mesh, making it a preferred choice in various applications.

- Enhanced Load Distribution: Square holes provide a uniform distribution of loads across the mesh surface, which can enhance the strength and durability of the material.

- Improved Stability: The square shape of the holes contributes to greater stability in the mesh structure, reducing the risk of deformation under pressure or stress.

- Better Containment: Square holes create a more consistent opening size, which is beneficial for containing materials of various shapes and sizes, ensuring they do not slip through the mesh.

- Versatile Applications: The design of square hole welded wire mesh makes it suitable for a wide range of applications, including fencing, industrial storage, and agricultural uses.

- Ease of Installation: Square hole mesh is often easier to cut and install compared to round hole mesh, allowing for efficient setup and modification.

Enhanced load distribution is crucial in applications requiring heavy-duty support. The uniformity of square holes allows for even load sharing, which can minimize weak points that might exist in round hole meshes.

Improved stability is another benefit, as the corners of square holes provide additional structural integrity, preventing the mesh from bending or warping under heavy loads, which is particularly important in construction and industrial settings.

Better containment ensures that materials, whether they are grains, aggregates, or livestock, are securely held within the confines of the mesh. This consistent opening size reduces the likelihood of accidental escape of smaller items, which can be a concern with round holes.

Versatile applications highlight the adaptability of square hole welded wire mesh. From agricultural fencing to reinforced concrete structures, its functional design meets diverse needs effectively.

Lastly, ease of installation is a significant advantage, as square hole mesh can often be worked with more straightforwardly than its round counterpart, allowing for quicker project completion and less labor-intensive processes.

When Should You Choose Square Hole Welded Wire Mesh Over Expanded Metal?

Choosing square hole welded wire mesh over expanded metal depends on specific project requirements and desired characteristics.

- Load-Bearing Capacity: Square hole welded wire mesh generally offers a higher load-bearing capacity compared to expanded metal, making it suitable for applications that require robust support.

- Uniformity in Openings: The square holes in welded wire mesh provide consistent and uniform openings, which can be crucial for applications where exact spacing is necessary, such as in filtration systems.

- Enhanced Security: The design of square hole welded wire mesh allows for greater security when used in fencing or barriers, as it is more difficult to cut through compared to the openings in expanded metal.

- Aesthetic Appeal: Square hole welded wire mesh can offer a cleaner, more finished look for architectural applications than expanded metal, which may be preferred in visible installations.

- Ease of Fabrication: Square hole welded wire mesh can be easier to cut and fabricate into various shapes and sizes, making it more adaptable for custom projects compared to the rigid structure of expanded metal.

Square hole welded wire mesh generally offers a higher load-bearing capacity compared to expanded metal, making it suitable for applications that require robust support. This feature is particularly beneficial in construction and industrial settings where durability is essential.

The square holes in welded wire mesh provide consistent and uniform openings, which can be crucial for applications where exact spacing is necessary, such as in filtration systems. This uniformity ensures that materials can pass through the mesh evenly without clogging or obstruction.

The design of square hole welded wire mesh allows for greater security when used in fencing or barriers, as it is more difficult to cut through compared to the openings in expanded metal. This added security makes it an ideal choice for areas that require enhanced protection.

Square hole welded wire mesh can offer a cleaner, more finished look for architectural applications than expanded metal, which may be preferred in visible installations. Its aesthetic appeal can make a significant difference in design-sensitive environments.

Square hole welded wire mesh can be easier to cut and fabricate into various shapes and sizes, making it more adaptable for custom projects compared to the rigid structure of expanded metal. This flexibility can save time and resources during the installation process.

What Should You Consider When Selecting Square Hole Welded Wire Mesh?

When selecting the best square hole welded wire mesh, several factors should be considered to ensure it meets your project requirements.

- Material: The material of the wire mesh, such as galvanized steel, stainless steel, or vinyl-coated wire, affects its durability and resistance to corrosion. Galvanized steel is typically used for outdoor applications due to its rust-resistant properties, while stainless steel offers superior strength and longevity in harsh environments.

- Wire Diameter: The diameter of the wire used in the mesh influences its strength and weight capacity. Thicker wires can bear more weight and withstand impacts better, making them suitable for heavy-duty applications, whereas thinner wires are lighter and more flexible, ideal for less demanding uses.

- Mesh Size: The size of the squares, or mesh openings, impacts what can be contained or filtered. Smaller mesh sizes are better for preventing the escape of small items or for use in applications like animal enclosures, while larger sizes can accommodate airflow and visibility in fencing or structural applications.

- Weld Quality: The quality of the welds affects the overall integrity and performance of the mesh. High-quality welding ensures that the intersections of the wires are strong and reliable, preventing breakage or deformity under stress, which is critical for structural applications.

- Coating and Finish: The type of coating or finish on the wire mesh can enhance its resistance to the elements and improve its aesthetic appeal. Options include powder coating for added color and protection, or special treatments for increased durability in specific environments, such as marine or chemical settings.

- Application Purpose: Understanding the intended use of the welded wire mesh is crucial for making the right selection. Whether it’s for construction, fencing, or agricultural use, each application has specific requirements for strength, durability, and appearance that should guide your choice.

- Compliance with Standards: Ensuring that the wire mesh complies with relevant industry standards and regulations is important for safety and performance. This includes certifications related to material quality, load-bearing capacity, and environmental impact, which can vary based on the intended application.

How Do Dimensions and Opening Size Affect Your Choice?

Opening Size: The opening size determines the mesh’s utility in filtering, containment, or support. Smaller openings are suitable for applications requiring fine filtration or containment of small animals, while larger openings are better for situations needing ventilation or drainage. Understanding the required opening size for your specific needs will guide you to the best choice.

Wire Gauge: The wire gauge indicates the thickness of the individual wires in the mesh, directly affecting its strength and resistance to bending or deformation. A lower gauge number means a thicker wire, which can offer greater durability, making it suitable for heavy-duty applications. Conversely, a higher gauge is lighter and may be adequate for temporary or less demanding uses.

Material Composition: The choice of material influences the mesh’s resistance to environmental factors, such as rust or corrosion. Galvanized steel is commonly used for outdoor applications due to its protective coating, while stainless steel offers superior durability and resistance to harsh conditions. Selecting the right material based on the environment is critical for long-lasting performance.

Mesh Pattern: The specific pattern of the mesh can enhance its functionality or visual appeal. Patterns can vary from a simple grid to more intricate designs, depending on the intended use. Choosing the right pattern can improve both the structural integrity and aesthetic integration of the mesh into its environment.

What Are the Key Factors in Pricing for Square Hole Welded Wire Mesh?

The key factors in pricing for square hole welded wire mesh include:

- Material Quality: The type of material used significantly impacts the price. Higher quality steel or galvanized wire is more expensive but offers better durability and resistance to corrosion, making it ideal for outdoor or industrial applications.

- Mesh Size and Thickness: The size of the square holes and the thickness of the wire contribute to the overall cost. Larger openings and thicker wires typically require more material and labor, which increases the price, but they also provide greater strength and load-bearing capabilities.

- Manufacturing Process: The method used to produce the welded wire mesh can affect pricing. Automated processes may reduce labor costs, while handcrafted methods can result in higher prices due to the skilled labor involved, but may offer superior quality and customization.

- Quantity Ordered: Bulk purchases often lead to lower prices per unit due to economies of scale. Manufacturers are usually willing to provide discounts for larger orders, which can be a significant factor for businesses looking to purchase extensive quantities.

- Market Demand: Fluctuations in market demand can influence prices. During periods of high demand, prices may increase due to the limited availability of materials or increased production costs, whereas lower demand can lead to decreased prices as manufacturers seek to move inventory.

- Customization Options: Custom features, such as specific dimensions or coatings, can raise the cost of square hole welded wire mesh. Customization often requires additional processes and materials, which contribute to a higher overall price.

- Shipping and Handling: The cost of shipping can be a significant factor, especially for large or heavy orders. Depending on the distance from the manufacturer and the shipping method, these costs can vary widely and should be factored into the overall pricing of the mesh.

Where Can You Find Reliable Suppliers for Square Hole Welded Wire Mesh?

Reliable suppliers for square hole welded wire mesh can be found through various channels:

- Online Marketplaces: Websites like Alibaba and Amazon offer a variety of suppliers with user reviews, allowing you to compare products and find the best square hole welded wire mesh.

- Industry Trade Shows: Attending trade shows related to construction and manufacturing can connect you with reputable suppliers who specialize in welded wire mesh products.

- Local Hardware Stores: Many local hardware or building supply stores carry welded wire mesh and can provide advice on the best options based on your specific needs.

- Manufacturer Directories: Online directories such as ThomasNet or Maker’s Row list manufacturers and suppliers of welded wire mesh, complete with contact information and product details.

- Networking with Industry Professionals: Engaging with architects, contractors, or builders can lead to recommendations for trusted suppliers who regularly source high-quality square hole welded wire mesh.

Online marketplaces allow for easy access to a plethora of suppliers, offering competitive pricing and customer feedback to help you make an informed decision. Be sure to check the ratings and reviews of each supplier for quality assurance.

Attending industry trade shows gives you the opportunity to meet suppliers face-to-face, examine product samples, and negotiate prices directly, which can often lead to better deals or bulk purchase discounts.

Local hardware stores can be a great resource for immediate needs and provide insights into which products are popular and reliable in your area, often having knowledgeable staff to assist you.

Manufacturer directories are excellent for finding specialized suppliers who may not have a strong online presence, allowing you to contact them directly for quotes and product specifications.

Networking with industry professionals can yield invaluable insights and recommendations, as they often have firsthand experience with various suppliers and can guide you toward those who provide the highest quality products.

What Should You Look for in a Quality Supplier?

When searching for a quality supplier of the best square hole welded wire mesh, consider the following factors:

- Material Quality: The best square hole welded wire mesh should be made from high-quality materials, such as galvanized steel or stainless steel, to ensure durability and resistance to corrosion. This is crucial for applications exposed to the elements or requiring long-term usage.

- Mesh Specifications: Look for suppliers that provide detailed specifications regarding the wire diameter, mesh opening size, and overall dimensions of the welded wire mesh. This information is essential to ensure that the mesh meets the specific requirements of your project.

- Manufacturing Standards: A reliable supplier should adhere to industry standards and certifications during the manufacturing process. This ensures that the welded wire mesh is produced under strict quality control measures, resulting in a product that meets performance expectations.

- Customization Options: Quality suppliers often offer customization options to cater to unique project needs, including different sizes, coatings, and mesh patterns. This flexibility allows you to obtain a product tailored to your specific application, whether for construction, fencing, or gardening.

- Delivery and Lead Times: A good supplier should provide clear information regarding delivery times and the ability to meet your project schedule. Timely delivery is critical to keeping your project on track and avoiding unnecessary delays.

- Customer Support: Evaluate the level of customer support offered by the supplier, including their responsiveness to inquiries and willingness to provide technical assistance. Strong customer service can significantly enhance your purchasing experience and help resolve any issues that may arise.

- Pricing Structure: Compare pricing from different suppliers, but also consider the overall value offered rather than just the lowest price. A supplier who provides high-quality products and excellent service may justify a higher price point in the long run.