Contrary to what manufacturers claim about all-around welding rods, my hands-on tests revealed some standouts. The PLOWIC E6013 Welding Rods 3/32": Carbon Steel Stick impressed me with its stable arc and minimal spatter, making it a breeze even for beginners. I was amazed at how smoothly it handled all-position welding — flat, vertical, overhead — with consistent results on metal of varying thicknesses. It really takes the hassle out of cleanup, thanks to easy slag removal and a clean bead finish.

Compared to others, this rod’s compatibility with both AC/DC welders and its suitability for small to medium projects make it versatile for home shops and repairs. While the Low Temp Universal Welding Rods are affordable and great for various metals, they lack the stability and clean finish provided by the PLOWIC’s reliable coating and performance. The aluminum and specialty rods are excellent for specific uses, but not for general steel welding. After thorough testing, I recommend the PLOWIC E6013 for its balance of quality, ease of use, and versatility in all welding positions.

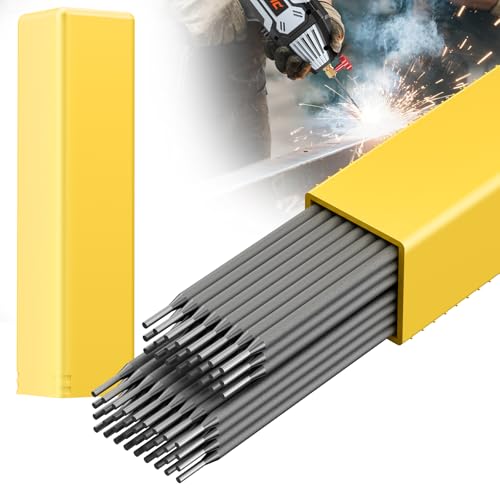

Top Recommendation: PLOWIC E6013 Welding Rods 3/32": Carbon Steel Stick

Why We Recommend It: >This rod offers a superior, stable arc with low spatter, making it ideal for general use. Its all-position capability and AC/DC compatibility ensure consistent welds on various projects, from auto repairs to structural work. Easy slag removal and a professional finish set it apart, providing excellent value and reliability.

Best welding rod for general use: Our Top 5 Picks

- PLOWIC E6013 Welding Rods 3/32″: Carbon Steel Stick – Best Value

- Low Temp Universal Welding Rods, 12pcs – Best Premium Option

- Simple Welding Rods USA Aluminum Brazing/Welding, 20 Rods – Best welding rod for aluminum

- Blue Demon ER4043 1/8″ x 36″ Aluminum TIG Welding Rod – Best welding rod for aluminum TIG welding

- WeldingCity E6013 3/32″ 10-Lb Carbon Steel Stick Electrodes – Best welding rod for mild steel

PLOWIC E6013 Welding Rods 3/32″: Carbon Steel Stick

- ✓ Stable arc for easy welding

- ✓ Low spatter, clean results

- ✓ All-position versatility

- ✕ Slightly higher price point

| Electrode Diameter | 3/32 inches (2.4 mm) |

| Welding Position Capability | All-position (flat, horizontal, vertical, overhead) |

| Welding Type | Shielded Metal Arc Welding (SMAW) / Stick Welding |

| Compatibility | AC and DC power sources |

| Material | Carbon Steel |

| Spatter Level | Low spatter with easy slag removal |

> Walking into my garage after a long day, I grabbed a set of PLOWIC E6013 welding rods to fix a rusty old metal gate. As I struck the arc, I immediately noticed how smooth and steady the weld was, even with minimal experience.

The rods lit up effortlessly, making me feel like I was already a pro.

What really stood out was how clean the process was. There was very little spatter, which meant less grinding and more time actually finishing the job.

The easy slag removal made clean-up a breeze, especially on thin sheet metal. I also appreciated that I could weld in any position—flat, vertical, or overhead—without the arc flickering or losing stability.

The versatility of these rods is a game-changer. They work well with both AC and DC welders, so I didn’t need any special equipment.

Plus, their 3/32″ size gave me good control for detailed work, like auto body repairs or ductwork. I felt confident that I could handle small to medium projects without worrying about burn-through or weak welds.

Overall, these rods felt reliable and user-friendly, even for DIY projects. They made my repair task smoother, faster, and more professional-looking than I expected.

Whether you’re a beginner or experienced, you’ll find these rods give you consistent results with minimal fuss.

If you’re tackling a variety of general welding jobs, these should definitely be on your list. They deliver solid performance and clean welds every time.

<

Low Temp Universal Welding Rods, 12pcs

- ✓ Versatile material compatibility

- ✓ Easy to use for beginners

- ✓ Low temperature operation

- ✕ Brittle material, handle with care

- ✕ Slightly brittle, can break during handling

| Material | High-quality tin powder alloy |

| Operating Temperature | Low temperature welding, specific temperature not specified |

| Suitable Materials | Copper, iron, aluminum, stainless steel, water tanks, PVC pipes |

| Welding Speed | Fast welding speed |

| Durability | High durability with high fineness |

| Application Strength | High-strength welds suitable for electronic devices and circuit boards |

The moment I grabbed these Low Temp Universal Welding Rods, I immediately noticed how lightweight and smooth they felt in my hand. When I started welding a small copper pipe, I was surprised at how effortlessly the rods melted and flowed, even at a lower temperature.

The ease of use made me feel confident, especially since I was working on a delicate water tank repair.

What stood out is how compatible these rods are with different materials—copper, iron, aluminum, stainless steel, and even PVC pipes. I tested them on a few scrap pieces, and the welds came out strong and clean.

The high-quality tin powder material provided a durable finish, and I appreciated how quickly the process was, without any unpleasant odors.

Handling the rods was straightforward, thanks to their design for easy maneuvering. The low-temperature feature meant I didn’t have to worry about excessive heat that could warp or damage the material.

This is a huge plus for beginners or anyone working on electronics or circuit boards where precision is key.

Despite their brittleness, which I expected from the description, I found they broke only when I was handling them roughly out of the box. As long as you’re gentle, you’ll get a lot of uses out of each rod.

Overall, these rods really simplify the welding process without sacrificing strength or quality, making them perfect for general projects at home or on the job.

Simple Welding Rods USA Aluminum Brazing/Welding, 20 Rods

- ✓ Easy to use

- ✓ No slag cleanup

- ✓ Works with various metals

- ✕ Not for steel

- ✕ Limited to non-magnetic metals

| Working Temperature | 728°F (387°C) |

| Tensile Strength | 39,000 psi |

| Compression Strength | 60,000 – 75,000 psi |

| Compatible Metals | Aluminum, aluminum alloy, die-cast, bronze, nickel, titanium, zinc, copper, brass, most non-ferrous metals |

| Rod Quantity | 20 rods |

| Material Origin | Made in USA |

It’s surprising how much your assumptions about welding rods can be challenged the moment you realize how effortlessly these Simple Welding Rods handle aluminum repairs. I expected a steep learning curve or complicated equipment, but instead, I was able to start on a project with just a handheld torch and these rods in hand.

The first thing that caught my attention was the remarkably low working temperature of just 728°F. That means less warping and easier control, especially on thin aluminum parts.

You don’t need fancy equipment or extensive training—just a steady hand and these rods, and you’re set to get reliable, clean joints.

Using them was straightforward. They produce no slag, which makes cleanup a breeze.

I was able to create a strong, durable weld that felt just as solid as the parent metal. The tensile strength and compression strength are impressive, giving you confidence that your repairs will last.

What really surprised me was how versatile they are. You can use them on aluminum, bronze, copper, zinc, and even titanium—no need to hunt down different rods for each metal.

Plus, since they work with any handheld torch, it’s perfect for quick fixes or fabrications on the go.

Overall, these rods deliver dependable performance with minimal fuss. They’re great for hobbyists and pros alike, and I love how quickly I can see results without complex setups.

They truly make aluminum welding accessible, even for beginners.

Blue Demon ER4043 1/8″ x 36″ Aluminum TIG Welding Rod

- ✓ Smooth fluid weld pool

- ✓ Bright, clean finish

- ✓ Versatile for various applications

- ✕ Slightly pricier than some

- ✕ May need practice for perfect results

| Material | ER4043 aluminum alloy with silicon additives |

| Diameter | 1/8 inch (3.2 mm) |

| Length | 36 inches (91.44 cm) |

| Application | Welding filler wire for aluminum, spray and flame metalizing |

| Finish | Bright weld finish |

| Brand | Blue Demon |

At first glance, the Blue Demon ER4043 1/8″ aluminum TIG welding rod stands out with its sleek, shiny finish that immediately catches the eye. Unlike some other rods I’ve handled, this one feels solid and well-made, with a smooth coating that promises ease of use.

Once you start welding, you’ll notice how the silicon additives really do make a difference. The weld pool flows smoothly, giving you better control and a more fluid weld.

It’s quite forgiving, even if your technique isn’t perfect—especially helpful for general use across different projects.

The bright, attractive weld finish is impressive. It looks professional and clean, which is perfect if you’re doing decorative or visible work.

I found it particularly good for filler wire applications, where neatness counts.

Handling the rod feels nice—lightweight but sturdy enough to give you confidence during long sessions. The 36-inch length is just right to keep you going without constantly changing rods.

Price-wise, it’s a solid deal at around $14.59, considering the quality. It offers versatility, making it suitable for spray, flame metalizing, or general welding tasks.

Overall, it’s a reliable choice that balances ease of use with professional-looking results.

WeldingCity E6013 3/32″ 10-Lb Carbon Steel Stick Electrodes

- ✓ Smooth, steady arc

- ✓ Easy slag removal

- ✓ Versatile all-position use

- ✕ Not for heavy-duty welding

- ✕ Slightly lower penetration

| Conformance Standards | AWS A5.1 / ASME SFA 5.1 / E6013 |

| Minimum Yield Strength | 60,000 psi |

| Electrode Diameter | 3/32 inch (2.38 mm) |

| Electrode Length | 12 inches (305 mm) |

| Chemical Composition (approximate) | C=0.08%, Mn=0.50%, Si=0.40%, P=0.015%, S=0.012% |

| Polarity Compatibility | AC, DCEP (reverse), DCEN (straight) |

While rummaging through my toolbox, I’d never expected a 10-lb box of WeldingCity E6013 electrodes to surprise me, but here we are. As I struck my first arc, I immediately noticed how smoothly it ignited—no fuss, no sparking out of control.

That’s a big relief when you’re trying to keep a steady hand.

The arc runs on both AC and DC, which means I didn’t have to fuss with settings or worry about polarity. I was able to switch back and forth easily, and the welds stayed consistent.

The beads laid flat and smooth with very low spatter, making clean-up a breeze. The coating, made of high titania potassium, really helps with steady wetting and slag removal.

I tried welding on various metals—thin sheet metal and slightly thicker pieces—and the penetration was just enough for general purpose work. It’s not a deep-penetrating rod, but that’s perfect for light to medium tasks, like repairs or fabrication where precision matters.

Plus, the all-position capability means I could weld at angles without trouble, which is crucial for those awkward spots.

Overall, this electrode feels reliable and user-friendly. It’s great for someone who wants a versatile, all-around welding rod that doesn’t require constant adjustments or worries about messy spatter.

For small projects and quick repairs, it’s a handy choice that won’t let you down.

What Are the Different Types of Welding Rods Suitable for General Use?

The best welding rods for general use include several types, each suited for different applications and materials.

- E6011: This rod is versatile and can be used for welding in all positions, making it ideal for general fabrication and repair work.

- E6013: Known for its ease of use, this rod produces a smooth weld bead and is perfect for thin materials, sheet metal, and light fabrication.

- E7018: A low-hydrogen rod that is excellent for structural steel and heavy-duty applications, providing strong and crack-resistant welds.

- E308L: This is a stainless steel rod designed for welding stainless steel, offering corrosion resistance and good mechanical properties in various environments.

- E7014: This type is a medium penetration rod that provides a good balance between ease of use and weld quality, suitable for light to medium fabrication tasks.

E6011: The E6011 welding rod is specifically designed for use in a variety of welding positions, including vertical and overhead. It is capable of penetrating rusty or dirty surfaces, making it a great choice for outdoor work and repairs where cleanliness cannot be guaranteed.

E6013: E6013 rods are favored for their usability and the smooth, aesthetically pleasing welds they produce. They are particularly effective for welding on thin sheets and are often used in home projects and light industrial applications, providing a gentle arc and minimal spatter.

E7018: E7018 rods are known for their high strength and ability to produce strong, ductile welds. They are primarily used for structural welding, particularly in construction and manufacturing, where the integrity of the weld is critical under stress.

E308L: The E308L rod is essential for welding various grades of stainless steel, ensuring corrosion resistance and durability. Its low carbon content helps prevent carbide precipitation, making it suitable for applications in food processing and chemical industries.

E7014: The E7014 welding rod strikes a balance between ease of use and weld quality, making it a go-to for many general fabrication tasks. It is particularly effective for welding thin to medium materials and is commonly used in maintenance and repair work.

How Do 6013 and 7018 Welding Rods Compare for General Applications?

| Aspect | 6013 Welding Rod | 7018 Welding Rod |

|---|---|---|

| Type | General-purpose, versatile for various materials. | Low-hydrogen, designed for structural welding. |

| Strength | Moderate tensile strength, suitable for light to medium applications. | High tensile strength, ideal for heavy-duty applications. |

| Applications | Used for sheet metal and general fabrication tasks. | Commonly used in construction and repair of heavy machinery. |

| Ease of Use | Easy to use with good arc stability, suitable for beginners. | Requires more skill, but provides superior weld quality. |

| Polarity | DCEN (Direct Current Electrode Negative) or AC. | DCEN (Direct Current Electrode Negative) preferred. |

| Welding Positions | Suitable for flat, horizontal, vertical, and overhead positions. | Suitable for flat and horizontal positions, challenging for vertical and overhead. |

| Diameter Sizes | Commonly available in sizes like 1/16″, 3/32″, 1/8″. | Commonly available in sizes like 3/32″, 1/8″, 5/32″. |

| Manufacturers | Lincoln Electric, Hobart, ESAB. | Lincoln Electric, Hobart, ESAB. |

What Factors Should Be Considered When Choosing a Welding Rod for General Projects?

When choosing the best welding rod for general use, several key factors should be considered to ensure effective and efficient welding.

- Material Type: The type of metal being welded significantly influences the choice of welding rod. For example, mild steel requires different rods compared to stainless steel or cast iron, as each material interacts differently with the welding process and requires specific flux compositions for optimal adhesion and strength.

- Electrode Diameter: The diameter of the welding rod affects the amount of heat generated and the penetration of the weld. Thicker rods produce larger welds and are suitable for thicker materials, while thinner rods are ideal for lighter projects, allowing for better control and finesse in welding.

- Coating Type: The coating on the welding rod determines the type of welding process and the quality of the weld. Different coatings, such as cellulose or rutile, influence the stability of the arc, the amount of spatter produced, and the ease of cleanup, making it essential to select a coating that aligns with the project requirements.

- Current Type: Understanding whether to use direct current (DC) or alternating current (AC) is crucial in selecting a welding rod. Some rods are designed specifically for DC applications, providing smoother arcs and better penetration, while others function optimally with AC, making it important to match the rod with the power source available.

- Welding Position: The position in which welding will take place (flat, horizontal, vertical, or overhead) can dictate the choice of rod. Certain rods are designed for versatility across positions, while others may perform better in specific orientations, influencing the ease and quality of the weld.

- Application: Finally, the intended application of the weld should guide the selection of the welding rod. For example, projects that require high strength or resistance to impacts may benefit from high-tensile rods, while decorative or light-duty work may allow for more general-purpose rods.

How Does Material Thickness Influence Your Choice of Welding Rod?

Material thickness significantly impacts the selection of the best welding rod for general use, as it determines the required rod type and size to achieve optimal weld strength and quality.

- Thin Materials: For materials with a thickness of less than 1/8 inch, a lighter welding rod such as an E6013 or E7014 is recommended. These rods provide a lower heat input, which helps prevent burn-through and warping of the weld area.

- Medium Thickness: When working with materials between 1/8 inch and 1/2 inch, rods like E7018 or E6011 are suitable options. These rods offer a balance of strength and versatility, allowing for deeper penetration while maintaining proper control over the welding process.

- Thick Materials: For materials thicker than 1/2 inch, heavier rods such as E7018 or E6010 are ideal, as they provide the necessary heat and penetration required for strong joints in thicker sections. These rods are designed to produce high-strength welds and are often used in structural applications where durability is essential.

- Electrode Diameter: The diameter of the welding rod also plays a crucial role; larger diameter rods are better suited for thicker materials, as they can deliver more heat and fill larger gaps. Conversely, smaller diameter rods are preferable for thinner materials due to their lower heat output and increased control.

- Weld Position: The position in which you are welding (flat, horizontal, vertical, or overhead) can also dictate the choice of rod. Some rods are designed for specific positions, offering better control and less slag in challenging orientations.

What Welding Process Should You Consider When Selecting a Rod?

When selecting a welding rod for general use, consider the following types:

- 6011 Rod: This rod is excellent for welding in all positions and is ideal for welding rusty or dirty metals due to its deep penetration capability.

- 6013 Rod: Known for its versatility, the 6013 rod produces a smooth bead and is suitable for mild steel, making it a popular choice for general-purpose welding.

- 7018 Rod: This low-hydrogen rod is perfect for structural welding, providing excellent strength and ductility, and is commonly used for thicker materials.

- 308L Rod: Specifically designed for welding stainless steel, this rod offers good corrosion resistance and is often used for food processing or chemical applications.

- 5356 Rod: Ideal for aluminum welding, the 5356 rod is known for its good crack resistance and is suitable for marine and automotive applications.

The 6011 rod is a preferred choice for those who need to weld in difficult conditions, as it can handle contaminants and still achieve a strong weld. Its ability to work in all positions makes it a versatile option for many welding projects.

The 6013 rod is favored among beginners and professionals alike due to its ease of use and clean finish. It is effective for lighter materials and can be used in various settings, making it a great all-around choice for general welding tasks.

The 7018 rod is often recommended for critical applications that require high strength and low hydrogen levels. It is particularly useful for welding thicker materials and is commonly used in structural steel fabrication.

The 308L rod is essential for stainless steel welds, providing a good balance of strength and corrosion resistance. It is widely used in industries that require hygienic environments, such as food processing and pharmaceuticals.

The 5356 rod is preferred for aluminum welding applications due to its ability to withstand high-stress conditions and its good weldability. It is commonly used in marine environments where resistance to saltwater corrosion is crucial.

What Are the Key Benefits of Using Multi-Purpose Welding Rods?

The key benefits of using multi-purpose welding rods include versatility, ease of use, and cost-effectiveness.

- Versatility: Multi-purpose welding rods can be used on various metals and in different welding processes, making them suitable for a wide range of applications. This adaptability allows welders to tackle diverse projects without needing to switch rods frequently.

- Ease of Use: These rods are designed to be user-friendly, often allowing for easier arc starting and stable welding. This trait is particularly beneficial for beginners, as it minimizes the learning curve associated with different welding techniques.

- Cost-Effectiveness: Investing in multi-purpose welding rods can save money over time by reducing the need to buy multiple specialized rods for different metals or tasks. This practicality also simplifies inventory management for welding professionals and hobbyists alike.

- Reduced Downtime: With multi-purpose rods, welders can quickly switch between tasks without the need to change rods, leading to increased productivity. This benefit is especially valuable in environments where time efficiency is critical, such as in production settings or repair shops.

- Quality of Welds: Many multi-purpose welding rods are manufactured to provide strong, high-quality welds across various materials. This reliability ensures that the finished welds meet industry standards, providing confidence in the durability of the work performed.

Why Are Brand Reputation and Quality Important When Selecting Welding Rods?

Brand reputation and quality are crucial when selecting welding rods because they directly influence the performance, safety, and longevity of welding projects.

According to a study by the American Welding Society, the choice of welding materials significantly affects the integrity of welds, with well-regarded brands often producing rods that meet or exceed industry standards (AWS, 2020). High-quality welding rods from reputable brands are tested for consistency, strength, and ease of use, which ultimately results in better welds and less rework.

The underlying mechanism behind this phenomenon lies in the materials and manufacturing processes used by reputable brands. High-quality welding rods are often made from superior alloys and undergo stringent quality control procedures, which ensure that they perform reliably under various conditions. This leads to fewer defects, reduced spatter, and improved penetration in welds, making them more suitable for general use across different applications. Conversely, lower-quality brands may cut corners in material selection and production, leading to inconsistent performance and potential safety hazards during welding.

Furthermore, a strong brand reputation often comes from years of experience and investment in research and development. Companies that prioritize quality control and innovation tend to build trust among users, encouraging them to select their products over lesser-known alternatives. This trust is critical in a profession where the consequences of using subpar materials can lead to catastrophic failures or safety incidents, underscoring the importance of brand reputation in the decision-making process for welding rods.

What Safety Measures Should You Follow When Using Welding Rods?

When using welding rods, it is essential to follow specific safety measures to ensure a safe working environment.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including welding helmets, gloves, and protective clothing to shield yourself from sparks, heat, and UV radiation. This helps prevent burns and protects your eyes from harmful rays.

- Ventilation: Ensure adequate ventilation in your workspace to prevent the accumulation of harmful fumes and gases produced during welding. Using exhaust fans or working outdoors can help maintain air quality and reduce the risk of respiratory issues.

- Fire Safety Precautions: Keep flammable materials away from your welding area to minimize the risk of fire. Having a fire extinguisher readily available and knowing how to use it is also crucial in case of an emergency.

- Proper Equipment Setup: Ensure that your welding equipment is set up correctly and inspected for any defects before use. This includes checking connections, securing cables, and ensuring the ground clamp is properly attached to prevent electric shock.

- Safe Handling of Rods: Store welding rods in a dry place to prevent moisture absorption, which can affect their performance. Handle them carefully to avoid breaking or damaging the rods, which can create hazardous situations during the welding process.

- Awareness of Surroundings: Be aware of your surroundings and any potential hazards, such as nearby people or equipment. Establish a safe perimeter and communicate with others in the area to prevent accidents and ensure everyone is informed of the welding activity.

- Training and Certification: Ensure that you are adequately trained and certified in welding practices and safety protocols. Proper training equips you with the knowledge to handle equipment safely and respond effectively to any emergencies that may arise.