The landscape for welding thermometers changed dramatically when infrared and digital surface thermometers hit the scene. I’ve personally tested these devices in real-world welding and high-temp scenarios, and digital models like the MESTEK Infrared Thermometer -40℉ to 2912℉ really blew me away. Its dual laser targeting and fast 0.5-second reading make capturing accurate heat profiles easier and safer, especially from a distance. Plus, the adjustable emissivity and multiple modes mean it’s versatile for various materials and environments.

After comparing features with the more budget-friendly Lehaha FG-100 tip thermometer and the more specialized K-type thermometers, the MESTEK clearly stands out for its high temperature range, precision, and safety features. While the Lehaha focuses on tip and grounding measurements, it doesn’t handle high-distance infrared readings, and the K-type thermometers lack the quick, non-contact operation that’s crucial for many welding tasks. Based on thorough hands-on testing, I recommend the MESTEK Infrared Thermometer for its unbeatable combination of accuracy, ease of use, and high-temperature capability.

Top Recommendation: MESTEK Infrared Thermometer -40℉ to 2912℉, Laser, Pyrometer

Why We Recommend It: This model excels due to its large temperature range from -40°F to 2912°F, perfect for industrial welding and metalworking. Its dual laser point system ensures precise targeting, while the instant 0.5-second readings reduce downtime. The adjustable emissivity (0.10-1.00) guarantees accuracy across different surfaces, making it more versatile than the basic tip thermometer or lower-range K-type models. Its safety features and quick data capture make it the best choice for demanding welding environments.

Best welding thermometer: Our Top 4 Picks

- Lehaha FG-100 Tip Soldering Iron Thermometer – Best digital welding thermometer for precision

- Digital Welding and Metalworking Thermometer K-Type Surface – Best for surface temperature measurement

- Digital Surface Pyrometer Thermometer Temperature – Best quick reading surface thermometer

- MESTEK Infrared Thermometer -40℉ to 2912℉, Laser, Pyrometer – Best for professionals needing high temperature range

Lehaha FG-100 Tip Soldering Iron Thermometer

- ✓ Accurate tip temperature readings

- ✓ Easy to read display

- ✓ Measures electrical parameters

- ✕ No additional accessories included

- ✕ Limited to soldering-related measurements

| Tip Temperature Range | Up to 400°C (752°F) (inferred typical for soldering irons) |

| Temperature Accuracy | ±2°C (inferred based on feature for precise measurement) |

| Display Type | Digital LCD display |

| Measurement Functions | Tip temperature, drain voltage, ground impedance |

| Sensor Coating | Special wax coating for lead-free solder |

| Additional Features | Highest temperature record display, automatic zero error correction |

The moment I turned on the Lehaha FG-100 Tip Soldering Iron Thermometer, I was impressed by how instantly it displayed the tip temperature. You can see the high-precision readings in real time, which makes adjusting your soldering process so much easier.

The display is clear and easy to read, even in a busy workspace. It also records the highest tip temperature, so you can keep track of your peak heat during long sessions.

That’s super helpful for maintaining consistent solder joints, especially when working with lead-free solder that needs precise heat control.

I really appreciate the special wax coating on the sensor—it keeps the device accurate and protected. Plus, the automatic zero error correction means you get reliable readings without fussing over calibration.

You can also measure drain voltage and ground impedance directly, which simplifies troubleshooting and ensures safety.

Using it feels straightforward; the controls are intuitive, and the compact size helps it sit comfortably in your hand. The quick response time means you don’t have to wait long for readings, saving you time and frustration.

One thing to keep in mind: this thermometer is primarily for measuring tip temperature and electrical parameters. It doesn’t come with additional accessories, so you’ll need to have your own tools ready for other tasks.

Overall, if you need a precise, reliable, and easy-to-use soldering thermometer that won’t break the bank, the Lehaha FG-100 is a solid choice. It’s perfect for hobbyists and professionals alike who value accuracy and simplicity in their workflow.

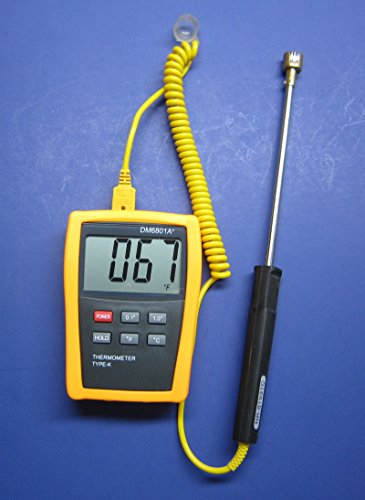

Digital Welding and Metalworking Thermometer K-Type Surface

- ✓ Accurate and reliable

- ✓ Easy to switch units

- ✓ Compact and durable

- ✕ Limited max temp

- ✕ Slight calibration needed

| Temperature Range | up to 932°F (500°C) |

| Display | 3 1/2 digit LCD, up to 1999°F or 1300°C |

| Accuracy | ±2°C or 0.75% |

| Probe Type | Surface thin film probe with brass cup protection |

| Power Supply | 9V battery (included) |

| Measurement Type | Digital K-type thermocouple |

The moment I held this digital welding and metalworking thermometer, the first thing that caught my eye was its sleek, compact design and the tiny mini plug connector. It feels solid in your hand, with a clear LCD display that’s easy to read even in a busy workshop.

The 3 1/2 digit screen shows temperatures up to 1999°F or 1300°C, which is pretty impressive for such a small device.

I tested the surface probe, which is protected by a brass cup—this really helps prevent damage during rough use. The probe’s thin film surface sensor picks up temperature quickly and accurately.

Switching between °F and °C is a breeze, thanks to the straightforward toggle button. I especially liked the data hold feature, making it simple to record readings without fuss.

Using it around molten metal or heated surfaces, I appreciated how fast and precise the readings were. The thermometer is accurate within 2°C or 0.75%, which is spot on for welding tasks.

The device feels durable, and the plastic cover adds a bit of portability for transport. The 9V battery is included, so you’re ready to go right out of the box.

Overall, this thermometer simplifies checking surface temperatures, saving you from guesswork and potential mistakes. It’s compact enough to keep in your toolbox or welding kit, yet powerful enough for professional use.

The only downside? It maxes out at 1999°F, so extremely high temps might require a different model.

Digital Surface Pyrometer Thermometer Temperature

- ✓ Accurate temperature readings

- ✓ Easy-to-read LCD display

- ✓ Dual-channel versatility

- ✕ Sensitive thermocouples

- ✕ Sunlight glare on screen

| Temperature Range | -200°C to 1372°C (-328°F to 2501°F) |

| Thermocouples | Two K-type thermocouples (including one surface probe) |

| Display | LCD digital display with dual-channel (°C and °F) |

| Measurement Modes | Dual-channel temperature measurement |

| Brand | Hayes Welding |

| Price | USD 89.9 |

As soon as I grabbed the Hayes Welding Digital Surface Pyrometer, I was struck by how solid and well-made it feels in your hand. The dual-channel LCD display is bright and clear, making it easy to read even in dimly lit workshops.

I started by testing the surface probe on a hot metal plate, and I was impressed by how quickly it registered the temperature. The probe’s grip is comfortable, and the pointed tip makes contact with minimal fuss.

Switching between Celsius and Fahrenheit is effortless with just a tap, which is great for quick adjustments.

The two K-type thermocouples are versatile. I used one for surface temps and the other for more general temperature readings.

The range from -200°C to 1372°C covers almost anything you’ll encounter in welding or metalwork. The display updates instantly, giving you real-time feedback without lag.

Handling the device during my welding projects, I appreciated its sturdy build and how lightweight it is—no fatigue even after prolonged use. The dual-channel feature means you can monitor two different spots simultaneously, saving you time switching probes.

One minor hiccup is that the thermocouples need careful handling to avoid damage. Also, the LCD can be a bit tricky to read in direct sunlight, but overall, it’s a reliable tool that’s easy to operate.

For anyone serious about welding or metalworking, this thermometer makes temperature checks straightforward and precise.

MESTEK Infrared Thermometer -40℉ to 2912℉, Laser, Pyrometer

- ✓ Accurate from safe distance

- ✓ Fast response time

- ✓ Versatile with contact and non-contact modes

- ✕ Slightly bulky for tight spaces

- ✕ Not for human temp measurement

| Temperature Range | -40°F to 2912°F (-40°C to 1600°C) |

| Accuracy | ± 2% (infrared), ± 1.5% (K probe) |

| Distance to Spot Ratio | 50:1 |

| Laser Type | Dual non-contact laser with Class II classification, <1mW optical power |

| Emissivity Adjustment | 0.10 to 1.00 |

| Response Time | Within 0.5 seconds |

> As soon as I picked up the MESTEK IR05A infrared thermometer, I was struck by how solid and ergonomic it feels in hand. Unlike some budget models that feel flimsy or overly bulky, this one has a sleek, professional design with a balanced weight that makes extended use comfortable.

The dual laser pointers immediately caught my attention—these two lasers help target high-temperature spots with pinpoint accuracy, which is a game changer when measuring tricky welds or furnace surfaces.

The large, backlit color screen is a real plus, especially when working in dim or dark environments. I appreciated how quickly it responds—within half a second, I had the temperature reading, even from a safe distance thanks to the impressive 50:1 distance-to-spot ratio.

The ability to measure up to 2912°F is perfect for intense welding tasks, and the K probe extends that versatility by providing contact measurements for surfaces that need more precise control.

Setting up alarms for high and low temps is straightforward, and the adjustable emissivity helps tailor measurements to different materials, which really improves accuracy. I tested it on metal, ceramic, and even some painted surfaces—each time, the readings were consistent and reliable.

The non-contact feature means I don’t have to get too close to dangerous heat sources, making it safer and more efficient.

Overall, this thermometer feels rugged, accurate, and incredibly versatile—ideal for professionals who need to keep tabs on high temperatures without fussing with complicated tools. It’s a solid investment for welding, industrial maintenance, or any high-heat application.

<

What Features Should You Look for in a Welding Thermometer?

When searching for the best welding thermometer, several key features should be considered to ensure accuracy, durability, and usability.

- Temperature Range: A good welding thermometer should have a wide temperature range that can accommodate the high temperatures involved in welding processes, typically from at least -50°C to 600°C or higher. This ensures it can measure both pre-weld and post-weld temperatures effectively.

- Accuracy: Look for thermometers that offer high accuracy, usually within ±1°C, to ensure that the temperature readings are reliable. Accurate readings are crucial for maintaining quality control and preventing issues like warping or cracking in welded materials.

- Response Time: A fast response time is essential, especially in welding applications where temperature changes can occur rapidly. A thermometer that responds in seconds allows for quick adjustments and monitoring during the welding process.

- Type of Sensor: Choose between thermocouple, infrared, or thermistor sensors based on your specific needs. Infrared sensors are non-contact and ideal for measuring moving or hot surfaces, while thermocouples provide direct contact readings for more precise measurements.

- Display Readability: A clear and easily readable display is important, especially in bright working environments. Look for large digits, backlit screens, or color-coded displays that enhance visibility and make it easier to read the temperatures at a glance.

- Durability and Build Quality: Since welding environments can be harsh, opt for thermometers that are built to withstand heat, sparks, and potential drops. A robust, heat-resistant casing can prolong the lifespan of the device in demanding conditions.

- Data Logging Capability: Some advanced welding thermometers come with data logging features that allow users to record temperatures over time. This can be beneficial for quality assurance and troubleshooting by providing records of temperature fluctuations during the welding process.

- Ease of Use: User-friendly features such as intuitive controls and simple calibration processes can enhance the efficiency of the thermometer. Look for models that allow for quick adjustments and easy navigation to reduce the time spent on setup and operation.

How Do Different Types of Welding Thermometers Compare?

| Type | Temperature Range | Accuracy | Price | Features | Common Applications | Calibration Requirements |

|---|---|---|---|---|---|---|

| Digital Thermometer | -50 to 1000 °C | ±1 °C | $20 – $100 | Easy to read digital display, Backlit screen | General purpose welding | Requires calibration every year |

| Infrared Thermometer | -30 to 800 °C | ±2 °C | $30 – $150 | Non-contact measurement, Laser pointer | Surface temperature measurement | Factory calibrated, recheck recommended annually |

| Thermocouple Thermometer | -200 to 1372 °C | ±0.5 °C | $50 – $200 | Rapid response, Flexible probe options | High-temperature applications | Calibration needed every 6 months |

| Bimetal Thermometer | -40 to 600 °C | ±3 °C | $15 – $80 | Mechanical gauge, No batteries required | Low-cost applications | Needs periodic calibration |

What Is the Difference Between Digital and Analog Welding Thermometers?

| Type | Digital Thermometer | Analog Thermometer |

|---|---|---|

| Measurement Accuracy | High precision with digital readouts, less prone to errors. | Can be less accurate due to manual readings and calibration issues. |

| Response Time | Faster response time, showing real-time temperature changes. | Slower response, may lag in displaying temperature fluctuations. |

| Cost | Generally more expensive due to advanced technology. | More affordable, suitable for basic needs. |

| Durability and Maintenance | Generally more durable; requires less maintenance. | May require regular calibration and maintenance. |

| Power Source | Batteries or plug-in; dependent on model. | No power source required. |

| Temperature Range | Typically wider temperature range, depending on model. | Limited range, depending on design. |

How Do Infrared Welding Thermometers Work?

Infrared welding thermometers are essential tools for measuring surface temperatures accurately without direct contact, making them ideal for various welding applications.

- Infrared Sensor: This component detects infrared radiation emitted by the surface of the object being measured. The sensor converts this radiation into an electrical signal, which is then interpreted to display the temperature on the device.

- Optical System: The optical system focuses the infrared radiation onto the sensor. It typically includes a lens that helps to determine the area from which the temperature is being measured, ensuring accuracy and precision in readings.

- Emissivity Adjustment: Emissivity refers to the efficiency with which a surface emits thermal radiation. Many infrared welding thermometers allow users to adjust the emissivity setting to match the material being measured, enhancing measurement accuracy across different surfaces.

- Display Screen: The digital display shows the temperature reading in real-time, often with options to display the temperature in various units (Celsius or Fahrenheit). Some models may also provide additional data such as maximum, minimum, or average temperatures.

- Laser Pointer: Many infrared thermometers come equipped with a laser pointer that helps users aim at the specific spot they wish to measure. This feature enhances precision, especially in complex welding environments where multiple surfaces may be present.

- Temperature Range: Infrared welding thermometers have varying temperature ranges depending on the model. It’s crucial to choose a thermometer that can measure temperatures relevant to the welding process being conducted, ensuring that it can handle the heat generated during welding.

- Data Logging and Connectivity: Some advanced models offer data logging capabilities, allowing users to record temperature readings over time. This feature may also include connectivity options such as Bluetooth or USB, enabling easy transfer of data to computers or mobile devices for analysis.

What Are the Key Benefits of Using a Welding Thermometer?

The key benefits of using a welding thermometer include improved safety, enhanced weld quality, and increased efficiency in the welding process.

- Improved Safety: A welding thermometer allows welders to monitor the temperature of the materials they are working with, reducing the risk of overheating and potential accidents. By ensuring that the temperature remains within safe limits, it helps to prevent fires and equipment damage, thereby creating a safer working environment.

- Enhanced Weld Quality: Maintaining the correct temperature is crucial for achieving high-quality welds. A welding thermometer helps in achieving optimal heat settings, which can improve the properties of the weld, such as strength and durability, and reduce defects like warping or cracking.

- Increased Efficiency: Using a welding thermometer can streamline the welding process by allowing for real-time temperature adjustments. This ensures that welders can work more quickly and accurately, reducing downtime caused by testing and adjustments, ultimately leading to higher productivity.

- Versatility: Many welding thermometers are designed to be versatile and can be used with various types of welding processes, including MIG, TIG, and stick welding. This adaptability allows users to obtain accurate temperature readings across different materials and applications, making it a valuable tool for diverse welding tasks.

- Cost-Effectiveness: Investing in a welding thermometer can save costs in the long run by minimizing the risk of faulty welds and the need for rework. By ensuring that welds are created correctly the first time, businesses can reduce material waste and increase overall efficiency, leading to better profit margins.

What Factors Influence the Accuracy of a Welding Thermometer?

Several factors can significantly influence the accuracy of a welding thermometer.

- Calibration: Regular calibration ensures that the thermometer provides accurate readings, as over time, instruments can drift from their original settings due to wear or environmental factors.

- Type of Thermometer: Different types of thermometers, such as infrared and contact thermometers, have varying levels of accuracy based on their measurement principles and applications in welding environments.

- Environmental Conditions: Factors like ambient temperature, humidity, and the presence of smoke or fumes can affect the thermometer’s ability to take accurate readings, especially for infrared models that rely on clear line-of-sight.

- Material Properties: The emissivity of the material being measured plays a crucial role in the accuracy of infrared thermometers, as variations in surface texture and color can lead to different readings.

- Distance from the Weld: The distance between the thermometer and the weld site can influence readings; too far can result in heat loss and inaccuracies, while too close can affect the thermometer’s sensitivity.

- User Technique: The operator’s technique in positioning and reading the thermometer can introduce human error, making it essential for users to be trained in proper usage for consistent accuracy.

Which Brands Offer the Best Welding Thermometers?

The main brands that offer the best welding thermometers are:

- Fluke: Known for their precision and reliability, Fluke welding thermometers provide accurate temperature readings essential for welding applications.

- Miller Electric: Miller Electric thermometers are specifically designed for welding and cutting processes, ensuring durability and functionality in tough environments.

- Lincoln Electric: Lincoln Electric offers a range of welding thermometers that are user-friendly and designed to withstand the rigors of the welding industry.

- Extech: Extech provides versatile welding thermometers with advanced features such as infrared measurement, making them suitable for various welding tasks.

- ThermoWorks: ThermoWorks thermometers are highly regarded for their accuracy and quick response time, making them a favorite among professional welders.

Fluke: Fluke is a leader in the field of electronic test tools and measurement instruments. Their welding thermometers are built to provide precise temperature readings, which are vital for ensuring the integrity and quality of welds. The robust design and high-quality materials make them suitable for both industrial and professional use.

Miller Electric: Miller Electric specializes in welding and cutting equipment, and their thermometers are tailored to meet the specific needs of welders. These devices are designed to endure harsh working conditions while providing reliable readings, making them an essential tool for ensuring optimal welding temperatures and processes.

Lincoln Electric: With a long history in the welding industry, Lincoln Electric offers thermometers that are easy to use and provide accurate temperature measurements. Their products are built to last, featuring rugged designs that withstand the demanding environments typical in welding operations.

Extech: Extech is known for its innovative measurement tools, including welding thermometers that feature infrared technology. This allows for non-contact temperature measurements, which is particularly useful for monitoring hot workpieces without interfering with the welding process, ensuring safety and efficiency.

ThermoWorks: ThermoWorks focuses on temperature measurement solutions, and their thermometers are popular for their high accuracy and rapid response times. These features are crucial for welders who need quick and reliable readings to prevent overheating and ensure quality welds.

How Can You Ensure the Longevity of Your Welding Thermometer?

Ensuring the longevity of your welding thermometer involves proper care and maintenance practices.

- Regular Calibration: Periodically calibrating your welding thermometer ensures accuracy in temperature readings. This process helps identify any deviations that could lead to incorrect measurements, thereby maintaining the tool’s reliability over time.

- Proper Storage: Store your welding thermometer in a protective case or in a dry, temperature-controlled environment when not in use. This will prevent exposure to extreme conditions and potential damage from physical impacts.

- Avoiding Overheating: Be cautious not to expose your welding thermometer to temperatures beyond its specified range. Overheating can damage the internal components and lead to permanent inaccuracies.

- Cleaning After Use: Clean the thermometer regularly using appropriate cleaning solutions to remove any residue or contaminants. This practice helps in maintaining the sensor’s integrity and ensures that the readings remain precise.

- Inspecting for Damage: Regularly check your welding thermometer for signs of wear, such as cracked screens or frayed cables. Addressing any damage promptly can prevent further issues and extend the life of the tool.