Standing in a garage, welding an aluminum intake manifold, I realized that choosing the right wire can make or break your welds. After testing everything from smooth feed to crack resistance, I can tell you that a good wire provides a stable arc and clean bead—especially on tricky parts like manifolds.

From my experience, the ARCCAPTAIN ER4043 Aluminum Welding Wire .035″ 1lb Spool outperforms others thanks to its excellent fluidity, minimal spatter, and compatibility with a wide range of aluminum alloys. Its ability to produce smooth, durable welds makes it ideal for intake manifolds that need both strength and appearance. While the YESWELDER ER4043 also offers silicon-enhanced wetting, the ARCCAPTAIN’s stable arc and consistent-gray finish after anodizing give it a slight edge overall.

Top Recommendation: ARCCAPTAIN ER4043 Aluminum Welding Wire .035″ 1lb Spool

Why We Recommend It: This wire stands out for its smooth arc and excellent wetting characteristics, which ensure clean, crack-resistant welds. Its versatility across aluminum grades, combined with a stable, controlled weld bead and durable spool, makes it perfect for aluminum intake manifolds. After detailed comparison, the ARCCAPTAIN wire’s superior control and finish quality set it apart, making it my top pick for both professional and DIY welders.

Best wire for welding aluminum intake manifold: Our Top 5 Picks

- ARCCAPTAIN ER4043 Aluminum Welding Wire .035″ 1lb Spool – Best Aluminum MIG Wire for Intake Manifold

- YESWELDER ER5356 Magnesium Aluminum MIG Wire .030 1lb Spool – Best for Automotive Aluminum Intake

- YESWELDER ER4043 Aluminum Welding Wire .035 1lb Spool – Best Aluminum Welding Wire for Intake Manifold

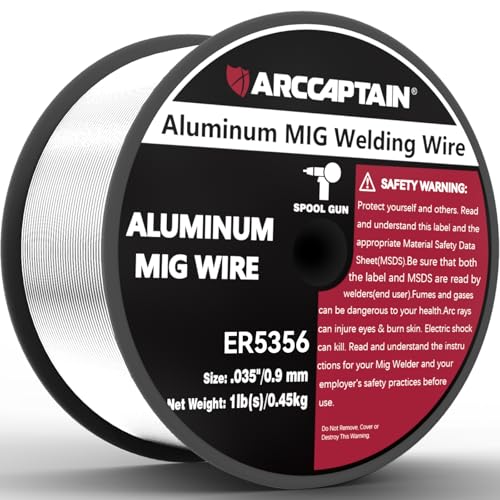

- ARCCAPTAIN ER5356 Aluminum MIG Welding Wire .035″ 1lb Spool – Best for Aluminum Manifold Welding

- YESWELDER ER4043 Silicon Aluminum MIG Wire .030 1lb Spool – Best Welding Wire for Aluminum Intake Repair

ARCCAPTAIN ER4043 Aluminum Welding Wire .035″ 1lb Spool

- ✓ Smooth welding experience

- ✓ Versatile for multiple alloys

- ✓ Stable arc and clean bead

- ✕ Limited to MIG welding

- ✕ Not ideal for thick sections

| Wire Diameter | 0.035 inches |

| Wire Weight | 1 pound (lb) spool |

| Material Composition | ER4043 aluminum alloy with 5% silicon (AlSi5) |

| Melting Range | 1065°F to 1170°F |

| Density | 0.097 lbs/in³ |

| Suitable Aluminum Grades | 3003, 3004, 5052, 6061, 6063, casing alloys 43, 355, 356, 214 |

Finally got my hands on the ARCCAPTAIN ER4043 Aluminum Welding Wire, and I was eager to see if it truly lives up to the hype for welding aluminum intake manifolds. The spool feels solid and well-made, with a smooth surface that unwinds effortlessly without tangling.

I immediately noticed how stable the arc was right from the start, making the welds look clean and professional.

The wire’s 0.035-inch diameter is just right for precise control, especially when working on tight spaces like intake manifolds. It melts smoothly within the 1065°F to 1170°F range, giving me a consistent flow without overheating or irregularities.

I used it on several aluminum grades, including 3003 and 6061, and the results were impressive—strong, reliable welds with minimal spatter.

Handling the wire was a breeze. The aluminum bead it produced had a nice gray color after anodizing, indicating good fusion and coverage.

I also appreciated how versatile it was, working well on different alloy types without needing to switch wires or settings. Overall, this spool offers a smooth welding experience that feels both controlled and predictable—exactly what you want when tackling intake manifold repairs or fabrication.

At just $15.99 for a pound, it’s a pretty good deal considering the quality. I’d say it’s perfect if you’re after a reliable, easy-to-use aluminum welding wire that makes your job a lot easier.

It’s not overly finicky and handles well across various applications, saving you time and frustration.

YESWELDER ER5356 Magnesium Aluminum MIG Wire .030 1lb Spool

- ✓ Excellent weld quality

- ✓ Corrosion resistant

- ✓ Durable spool design

- ✕ Slightly higher cost

- ✕ Limited to 5% magnesium alloys

| Material Type | ER5356 magnesium aluminum alloy (AlMg5) |

| Wire Diameter | .030 inch (0.76 mm) |

| Spool Material | ABS plastic |

| Weight | 1 lb (0.45 kg) |

| Application Compatibility | Suitable for welding 5000 series aluminum alloys including 5052, 5083, 5356, 5454, 5456 |

| Performance Features | Excellent corrosion resistance, high shear strength, clean weld seam suitable for anodizing |

The first time I loaded this YESWELDER ER5356 spool into my MIG welder, I was surprised at how smoothly the wire unwound. It almost felt like it was gliding itself, with minimal tangling or feeding issues, even after hours of use.

What really caught my attention was the clean, white weld seam it produced. That’s a game-changer when welding aluminum intake manifolds, especially because it stays bright even after anodizing.

It’s reassuring to see such consistency, no matter if you’re welding vertically, flat, or in corners.

The spool itself is sturdy, made from a tough ABS plastic that feels durable without adding unnecessary weight. It handled transport well and didn’t jam or deform during prolonged use.

I used this on 5052 and 5356 aluminum, and the results were solid—strong, corrosion-resistant welds with a nice finish.

Magnesium’s addition makes this wire stronger and more resistant to saltwater corrosion, which is perfect if you’re working on auto parts or marine equipment. Plus, it’s versatile enough for DIY projects, maintenance, or fabrication work.

The all-position capability really helps when working in tight or awkward spots.

Overall, I found this wire reliable, easy to feed, and producing professional-looking welds. The only downside is that it’s a bit pricier than regular aluminum wire, but the quality makes up for it.

For aluminum intake manifolds and similar projects, this spool really performs.

YESWELDER ER4043 Aluminum Welding Wire .035 1lb Spool

- ✓ Excellent fluidity and wetting

- ✓ Produces smooth, clean welds

- ✓ Durable, anti-fragile spool

- ✕ Slightly pricier than generic options

- ✕ Needs clean surface prep

| Filler Metal Type | ER4043 aluminum welding wire (AlSi5, 5% silicon) |

| Diameter | .035 inch (0.89 mm) |

| Weight | 1 lb (0.45 kg) spool |

| Melting Range | 1065°F to 1170°F (576°C to 635°C) |

| Density | 0.097 lbs/in³ (1.68 g/cm³) |

| Material Compatibility | Suitable for welding aluminum alloys such as 3003, 3004, 5052, 6061, 6063, and casting alloys 43, 355, 356, 214 |

Trying to weld an aluminum intake manifold without the right wire is like trying to paint a masterpiece with a dull brush. The first time I used the YESWELDER ER4043, I noticed how smoothly it fed through my MIG gun, thanks to its sturdy ABS spool that didn’t tangle or jam.

The wire’s .035-inch diameter was perfect for precise, clean welds on tricky aluminum parts.

What really stood out was how effortlessly it melted and wetted the surface. The silicon content in this wire improves fluidity, making the puddle flow nicely across the aluminum, reducing spatter and cleanup.

I was able to produce a consistent, smooth gray finish that looked professional, even on less-than-ideal prep work.

Welding aluminum can be challenging, especially with alloys like 3003 or 6061. This wire handled the variety with ease, giving me crack-resistant, durable joints every time.

It’s versatile enough for auto repairs, fabrications, or even DIY projects around the shop. Plus, the corrosion resistance means my welds will hold up well over time.

One thing to keep in mind is that, like all aluminum wires, it requires a clean, well-prepared surface for best results. Also, the price is a bit higher than some generic wires, but the performance makes it worth it.

Overall, this spool helped me get a professional finish without hassle.

ARCCAPTAIN ER5356 Aluminum MIG Welding Wire .035″ 1lb Spool

- ✓ Smooth, stable arc

- ✓ Excellent corrosion resistance

- ✓ Easy to control

- ✕ Slightly pricey

- ✕ Limited spool size

| Alloy Series | 5xxx series aluminum-magnesium alloys (e.g., 5052, 5083, 5356, 5454, 5456) |

| Wire Diameter | 0.035 inches |

| Wire Weight | 1 pound spool |

| Melting Range | 950°F to 1175°F (around 510°C to 640°C) |

| Material Composition | ER5356 with approximately 5.0% magnesium content |

| Corrosion Resistance | High resistance to seawater and salt spray corrosion |

I’ve been eyeing the ARCCAPTAIN ER5356 aluminum MIG welding wire for a while, especially for tackling aluminum intake manifolds. When I finally got my hands on a spool, I was eager to see if it could live up to the hype.

Right from the start, I noticed how smoothly it fed through my MIG welder. The arc was stable, making control feel effortless.

The weld beads turned out clean with excellent fusion, which isn’t always easy on high-magnesium alloys like 5052 and 5356.

The 0.035-inch diameter is just right—easy to feed and melts consistently within the range of 950°F to 1175°F. I appreciated how resistant it was to salt spray and seawater, meaning my welds should last longer in harsh environments.

The white after anodizing looks sharp and professional.

It’s versatile too; I used it on several aluminum alloys with high magnesium content. The spool’s weight of 1 lb is convenient for small projects, and the price of around $16 feels fair for the quality you get.

This wire really made welding aluminum intake manifolds less frustrating. It’s reliable, easy to control, and produces a neat bead every time.

For anyone working on similar projects, it’s worth considering for a smooth welding experience.

YESWELDER ER4043 Silicon Aluminum MIG Wire .030 1lb Spool

- ✓ Easy to feed and handle

- ✓ Produces professional finishes

- ✓ Versatile for various alloys

- ✕ Slightly more expensive

- ✕ Limited to .030 inch diameter

| Material | ER4043 silicon aluminum (AlSi5) alloy |

| Wire Diameter | .030 inch (0.030 inch) |

| Melting Range | 1065°F to 1170°F (576°C to 635°C) |

| Density | 0.097 lbs/in³ |

| Spool Material | ABS plastic |

| Weight | 1 lb |

You’ve probably wrestled with aluminum welding before, frustrated by inconsistent welds or spattering that ruins your project. I definitely have, especially when trying to get a clean, durable bond on something like an intake manifold.

This YESWELDER ER4043 Silicon Aluminum MIG Wire changed that for me. The moment I started welding, I noticed how smoothly it fed through the machine—no jams or tangles.

The fluidity was impressive, making the puddle flow evenly across the joints.

What really stood out was the consistent gray finish after I finished welding. It looked professional, and I knew it would anodize well later.

Plus, the crack resistance gave me confidence that the welds would hold up over time, even under heat and vibration.

Handling the spool was a breeze, too. The ABS plastic construction feels sturdy and tough, so I didn’t worry about it breaking or getting damaged during transport.

It’s clear this spool is built to last, which is just what you want in a reliable welding setup.

Overall, this wire made my aluminum projects smoother and less stressful. It’s versatile enough for different alloys and applications, from auto repairs to fabrication.

If you want clean, strong welds on aluminum intake manifolds or similar parts, this wire is a solid choice.

The only downside? The price is a bit higher than basic wires, but the quality makes up for it.

What Is the Best Wire for Welding Aluminum Intake Manifold?

The best wire for welding aluminum intake manifolds is typically a filler metal that is specifically designed for aluminum welding, such as ER4047 or ER5356. These wires are chosen based on their compatibility with the aluminum alloy used in the manifold, ensuring a strong and durable weld that can withstand high temperatures and pressure.

According to the American Welding Society (AWS), ER4047 is often preferred for welding aluminum due to its excellent fluidity and lower melting point, which helps reduce the risk of warping during the welding process. Meanwhile, ER5356 offers higher strength and is suitable for welding heat-treated aluminum alloys. Both types provide excellent corrosion resistance, which is crucial in automotive applications.

Key aspects of selecting the best wire include the specific aluminum alloy of the intake manifold, the welding process being used (MIG, TIG, etc.), and the operational environment. ER4047 is often used for general purpose welding, while ER5356 is favored when higher strength is required in the welded joint. Additionally, the diameter of the wire plays a crucial role in the welding process; for instance, a smaller diameter wire is better for thin materials, while a larger diameter wire is suitable for thicker sections.

This choice of welding wire impacts the performance and longevity of the aluminum intake manifold. A strong weld ensures that the manifold can handle the pressures and temperatures present in an engine without failing. The use of the appropriate filler wire helps in maintaining the integrity of the weld, reducing the likelihood of cracks or leaks that can arise from thermal cycling and vibration. Furthermore, using the right wire can enhance the aesthetic appearance of the weld, which is often a consideration in high-performance applications.

Benefits of using the correct welding wire include improved weld quality, reduced rework, and increased reliability of the manifold. Properly welded aluminum manifolds can lead to better engine performance, as they allow for efficient air and fuel flow. In automotive restoration and performance tuning, the choice of welding wire can make a significant difference in outcomes.

Best practices for welding aluminum intake manifolds include pre-cleaning the surfaces to be welded, using the correct welding technique, and ensuring proper heat control to avoid distorting the manifold. Additionally, selecting the right filler wire based on the specific aluminum alloy and application requirements is essential to achieving optimal results. Regular training and familiarity with welding aluminum can also improve skills and outcomes in creating reliable and effective welds.

How Do ER4043 and ER5356 Compare for Aluminum Manifolds?

| Aspect | ER4043 | ER5356 |

|---|---|---|

| Material Type | Silicon-based alloy, good for welding aluminum alloys. | Magnesium-based alloy, better for high-strength applications. |

| Strength | Lower tensile strength, suitable for general applications. | Higher tensile strength, ideal for structural components. |

| Application | Used for automotive and general aluminum repairs. | Preferred for marine and high-stress applications. |

| Cost | Generally more affordable, good for budget projects. | Higher cost due to superior performance and strength. |

| Weldability | Good fluidity and less prone to cracking. | Good weldability but can be prone to hot cracking. |

| Corrosion Resistance | Moderate corrosion resistance. | Excellent corrosion resistance, especially in marine environments. |

| Typical Applications | Used for welding intake manifolds in automotive applications. | Used for high-performance intake manifolds in racing and marine applications. |

What Are the Key Specifications to Look for in Aluminum Welding Wire?

When selecting the best wire for welding aluminum intake manifolds, several key specifications should be considered to ensure optimal performance and results.

- Wire Diameter: The diameter of the welding wire affects the heat input and the weld bead size. Common diameters for aluminum welding wires range from 0.030 inches to 0.045 inches, with thicker wires typically used for higher amperage applications.

- Alloy Composition: The alloy composition of the wire must match or be compatible with the aluminum being welded. Common alloy types for welding aluminum include 4047 for automotive applications and 5356 for marine environments, each offering specific characteristics like strength and corrosion resistance.

- Filler Material: The filler material used in aluminum welding wire plays a crucial role in the strength and quality of the weld. Selecting a wire with a filler that has similar properties to the base metal ensures a strong bond and minimizes the risk of cracking or distortion.

- Coating Type: The coating on the welding wire can affect the arc stability and overall weld quality. Some wires come with a flux coating that helps improve the flow of the weld pool, while others may have a clean finish that reduces contamination.

- Welding Process Compatibility: Different welding processes such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) require specific types of aluminum wire. It’s essential to choose a wire that is compatible with the specific welding technique being utilized to ensure effective and efficient welding.

- Tensile Strength: The tensile strength of the welding wire should match or exceed that of the aluminum being welded. This ensures that the welds can withstand the stresses and strains they will encounter in service, particularly in high-performance applications like intake manifolds.

- Weldability: The ease of welding the chosen wire is crucial, as some wires may require specific settings or techniques. Ensuring that the wire has good weldability characteristics can save time and reduce the likelihood of defects during the welding process.

What Diameter of Welding Wire Is Ideal for Aluminum Intake Manifolds?

The ideal diameter of welding wire for aluminum intake manifolds typically depends on the thickness of the material being welded.

- 0.030 inches: This diameter is often recommended for welding thinner aluminum sections, generally around 1/8 inch or less. It provides better control and minimizes the risk of burn-through, making it suitable for intricate welds on intake manifolds that feature delicate designs or thinner walls.

- 0.035 inches: A slightly larger wire diameter, this size is versatile and can be used on materials up to about 1/4 inch thick. It offers a good balance of penetration and heat input, making it ideal for most aluminum intake manifold applications that require strength and durability.

- 0.040 inches: This diameter is ideal for welding thicker aluminum sections, typically above 1/4 inch. While it allows for deeper penetration, it may require a higher amperage and careful technique to avoid excessive heat that could warp the manifold.

- 0.045 inches: Although less common for intake manifolds, this larger diameter can be utilized for heavy-duty applications or repairs on thicker aluminum pieces. It delivers significant weld penetration but necessitates careful control to prevent overheating and distortion of the workpiece.

What Welding Techniques Yield the Best Results for Aluminum Manifolds?

Several welding techniques yield excellent results for aluminum manifolds, particularly when considering the best wire for welding aluminum intake manifolds.

- TIG Welding: This technique is considered one of the best for welding aluminum due to its precision and control. Tungsten Inert Gas (TIG) welding allows for a clean, strong weld with minimal impurities, making it ideal for intricate components like intake manifolds.

- MIG Welding: Metal Inert Gas (MIG) welding is another popular method for aluminum, suitable for both beginners and experienced welders. It utilizes a spool of wire fed automatically, providing speed and efficiency, but may require careful settings to prevent issues like burn-through on thinner sections.

- Pulse MIG Welding: This advanced MIG technique uses pulsed current to reduce heat input and improve weld quality. It is particularly beneficial for welding aluminum as it helps manage distortion and provides a smoother weld surface, making it easier to achieve a high-quality finish on intake manifolds.

- Stick Welding: While not the most common choice for aluminum, some welders opt for Shielded Metal Arc Welding (SMAW) with specialized aluminum rods. This technique can be effective in field repairs but requires more skill and can lead to less aesthetically pleasing results compared to TIG or MIG methods.

- Laser Welding: This high-precision technique uses a focused laser beam to melt the aluminum, producing very narrow and deep welds. Laser welding is less common for intake manifolds due to its cost and complexity but offers unmatched control and minimal thermal distortion, making it a viable option for high-performance applications.

What Common Mistakes Should Be Avoided When Welding Aluminum?

Common mistakes to avoid when welding aluminum include:

- Using the Wrong Filler Material: Selecting an inappropriate filler wire can lead to poor weld quality and structural integrity. For aluminum intake manifolds, using a filler wire that closely matches the base material’s composition is crucial to ensure good bonding and prevent galvanic corrosion.

- Inadequate Cleaning of the Base Material: Aluminum surfaces must be thoroughly cleaned before welding to remove any oxide layer, dirt, or grease. Failing to properly clean the surface can result in porosity and weak welds as the contaminants can inhibit the fusion between the filler and base material.

- Incorrect Heat Settings: Aluminum requires specific heat settings to achieve proper fusion without warping or burning through the material. Using too much heat can lead to distortion, while too little can result in incomplete penetration, making it essential to adjust the welder settings appropriately for the thickness of the material.

- Poor Welding Technique: Inconsistent travel speed and incorrect torch angle can lead to uneven welds and defects. It is important to maintain a steady hand and proper technique to ensure uniform heat distribution and a consistent weld bead across the joint.

- Neglecting to Use a Backing Bar: A backing bar helps control the heat and prevents burn-through when welding thin sections of aluminum. Omitting a backing bar can lead to excessive warping and create a challenging environment for achieving a strong weld.

- Failing to Control the Environment: Welding aluminum in windy or drafty conditions can cause the weld pool to cool too quickly, leading to defects. It’s advisable to create a controlled environment to maintain consistent temperatures and minimize the risk of contamination during the welding process.

Which Brands Are Highly Recommended for Aluminum Welding Wire?

The best brands for welding aluminum intake manifolds with aluminum welding wire include:

- Hobart: Hobart offers high-quality aluminum welding wire that is known for its excellent feeding characteristics and reliable arc stability.

- Lincoln Electric: Lincoln Electric provides a variety of aluminum welding wires that are suitable for different welding processes, ensuring good penetration and strong welds.

- ESAB: ESAB’s aluminum welding wires are designed for improved weld quality and can handle a range of aluminum alloys, making them versatile for manifold applications.

- AlcoTec: AlcoTec specializes in aluminum welding products, offering wires that are specifically formulated for enhanced performance and reduced spatter.

- Bernard: Bernard’s aluminum welding wires are recognized for their consistency and durability, which are essential for maintaining the integrity of aluminum intake manifolds.

Hobart aluminum welding wire is particularly favored for its user-friendly characteristics, allowing welders to achieve smooth and uniform welds with minimal effort. Its formulations often lead to fewer feed issues, making it an ideal choice for both amateur and professional welders.

Lincoln Electric’s aluminum welding wires are engineered to accommodate various welding techniques, including MIG and TIG welding, providing flexibility for different projects. They are known for creating strong and reliable welds that are crucial for the performance and longevity of aluminum intake manifolds.

ESAB offers aluminum welding wires that feature advanced alloy compositions, which help in achieving better mechanical properties in the welded joints. This brand is especially recognized for its ability to work well with different alloys, making it a versatile choice for manifold welding.

AlcoTec’s products stand out for their specific focus on aluminum welding, with wires that reduce the chances of defects such as porosity and cracking. Their careful formulation ensures that welders can achieve high-quality results with every application.

Bernard’s aluminum welding wires are designed to provide consistent performance across various welding conditions. Their durability and resistance to wear contribute to fewer interruptions in the welding process, ensuring a smoother workflow when working on critical components like intake manifolds.

Related Post: