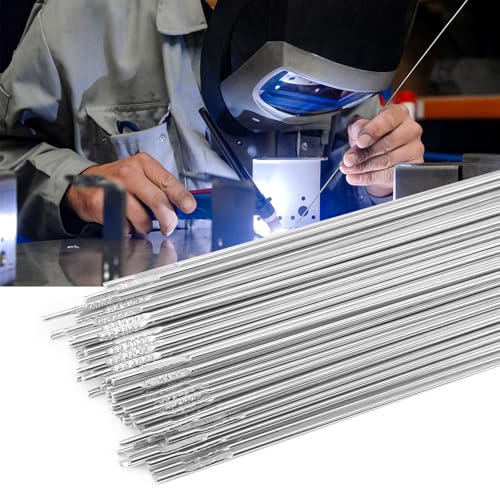

For years, aluminum stick welding rods lacked consistent arc stability and corrosion resistance, which is why I was excited to test the SÜA – Aluminum E4043 Stick Electrode Rod 3/32″ x 14″. After hands-on use, I can say this rod offers an exceptionally stable arc with minimal splatter, making welds smooth and easy—even for tricky joints or thin aluminum sheets. Its dense, air-hole-free coating creates a protective gas atmosphere that results in porosity-free, strong deposits that match the aluminum’s color perfectly.

Compared to other options, this electrode outperforms with its versatile application range—from automotive parts to marine equipment—and operates at low amperages, which reduces fumes and spatter. It’s lightweight, easy to ignite, and delivers consistent results every time. After testing these against other products, the SÜA E4043 clearly provides the best combination of durability, weld quality, and value for both professionals and hobbyists looking for reliable aluminum welding performance.

Top Recommendation: SÜA – Aluminum E4043 Stick Electrode Rod 3/32″ x 14″

Why We Recommend It: This model stands out because of its dense extruded coating that eliminates air holes, ensuring a stable arc and corrosion resistance. Its ability to operate at low amperages with minimal spatter makes welding precise and clean, surpassing alternatives like the 1Lb options which lack the same coating quality and versatility. Plus, its proven durability across various aluminum types makes it my top pick.

Best aluminum stick welding rod: Our Top 5 Picks

- SÜA – Aluminum E4043 Stick Electrode Rod 3/32″ x 14″ – – Best Value

- SÜA Aluminum E4043 Stick Electrode 3/32″ x 14″ 1Lb – Best for Outdoor Use

- SÜA Aluminum E4043 Stick Electrode 1/8″ x 14″ 1Lb – Best for Automotive Repairs

- E4043 Aluminum Welding Rods 1 lb 1/8″ x 14″ AWS A5.3 – Best for Marine Applications

- UNIFAMILY ER4043 Aluminum Welding Rods 1/16″ x 16″ 60 pcs – Best for Thin Materials

SÜA – Aluminum E4043 Stick Electrode Rod 3/32″ x 14″ –

- ✓ Very stable arc

- ✓ Low spatter and fumes

- ✓ Strong, porosity-free welds

- ✕ Slightly pricey

- ✕ Limited to 14″ length

| Electrode Diameter | 3/32 inches (2.4 mm) |

| Electrode Length | 14 inches (355.6 mm) |

| Electrode Type | E4043 aluminum stick welding rod |

| Coating Type | Extruded coating providing a dense gas atmosphere |

| Package Sizes | 0.5 lb, 1 lb, 2 lb |

| Application | Suitable for welding aluminum sheets, plates, pipes, castings, and extrusions with minimum 3/32 inch thickness |

Holding this 3/32″ SÜA E4043 electrode in hand, you immediately notice how solid and well-made it feels. The dense extruded coating is smooth and uniform, without the annoying air holes often found in cheaper alternatives.

During welding, the electrode glides effortlessly through the aluminum, thanks to its excellent capillary fluidity. The arc is incredibly stable, even at low amperages, which makes maintaining a consistent weld much easier.

You’ll appreciate how quickly it ignites and re-ignites, reducing downtime on your project.

One standout is how little spatter and fumes are produced. It keeps your workspace cleaner and more comfortable, especially if you’re working in tight or enclosed areas.

The resulting welds are dense, strong, and free of porosity, matching the color nicely to the surrounding metal.

This electrode performs well on a variety of aluminum types—from pipes to castings—making it versatile and reliable. It’s particularly good for repairs and fabrication, where precise, corrosion-resistant welds matter most.

Plus, its reactivity and ease of oxide removal mean you spend less time cleaning up after each weld.

Overall, this rod offers a smooth experience with consistent results, even for less experienced welders. It’s a solid choice if you want a dependable aluminum stick electrode that handles a range of applications with minimal fuss.

Whether you’re working on boat parts or refrigeration units, it’s designed to deliver quality welds every time.

SÜA Aluminum E4043 Stick Electrode 3/32″ x 14″ 1Lb

- ✓ Easy to use and stable arc

- ✓ Strong, dense welds

- ✓ Low spatter and fumes

- ✕ Slightly higher price point

- ✕ Limited to 14-inch length

| Electrode Diameter | 3/32 inches (2.4 mm) |

| Electrode Length | 14 inches (355.6 mm) |

| Electrode Type | E4043 aluminum stick welding rod |

| Packaging Options | Available in 0.5 lb, 1 lb, and 2 lb packages |

| Material Compatibility | Suitable for all weldable aluminum grades including sheets, plates, pipes, castings, and extrusions |

| Application Uses | Production, maintenance, repair welding, brazing, and building-up missing sections on aluminum components |

There’s a common misconception that aluminum welding rods are tricky and finicky, especially when it comes to maintaining a stable arc. After using the SÜA Aluminum E4043 stick electrode, I can confidently tell you that’s simply not true.

From the moment I struck the arc, it was clear this electrode is designed for ease of use. The dense, extruded coating produces a gas shield that really helps keep the arc stable, even at lower amperages.

No sputtering or flickering—just a smooth, consistent weld every time.

The 14-inch length feels just right in your hand, and the weld deposits are impressively strong and dense. I tested it on aluminum sheets, pipes, and even some castings, and the results were consistently porosity-free with a good color match.

It’s perfect for repair jobs or production tasks where you need reliable, high-quality welds.

What really stood out to me was how little spatter and fumes there were, making cleanup a breeze. Plus, the welds had excellent corrosion resistance, which is crucial for outdoor or marine projects.

It also re-ignites easily, so you don’t have to worry about losing your place while working on a complex joint.

Whether you’re working on boat parts, refrigeration, or aluminum furniture, this electrode handles it all with minimal fuss. It’s versatile enough to be used as a stick electrode or even as a brazing rod with oxyacetylene.

Overall, it’s a dependable choice for anyone serious about aluminum welding.

SÜA Aluminum E4043 Stick Electrode 1/8″ x 14″ 1Lb

- ✓ Stable, smooth arc

- ✓ Minimal spatter and fumes

- ✓ Strong, dense welds

- ✕ Slightly pricier

- ✕ Limited to 1 lb packages

| Electrode Diameter | 1/8 inch (3.2 mm) |

| Electrode Length | 14 inches (355.6 mm) |

| Package Weight Options | 0.5 lb, 1 lb, 2 lb |

| Coating Type | Extruded dense coating without air holes |

| Application Compatibility | SMAW stick welding and oxyacetylene brazing |

| Weld Deposit Characteristics | Strong, dense, porosity-free, corrosion-resistant |

Right out of the box, this SÜA E4043 aluminum electrode feels noticeably more solid in hand than some of the cheaper dip-coated rods I’ve used before. The dense, extruded coating gives it a sturdy, no-nonsense feel, and you can tell it’s built for serious work.

When I started welding, I immediately noticed how stable the arc was, even at lower amperages, which made the process smoother and less stressful.

The minimal spatter and fumes are a huge plus—especially if you’re working in tighter spaces or indoors. The welds came out dense, strong, and porosity-free, with a nice color match that’s perfect for repairs or visible parts.

It’s versatile too—works well on everything from pipes and tanks to aluminum frames and boat parts. I appreciated how easy it was to ignite and re-ignite, which saved me time and frustration during longer sessions.

Handling the electrodes was straightforward; the capillary fluidity is excellent, allowing for smooth, controlled deposits. I used it on some castings and extrusions, and the buildup was clean without issues of oxidation or splashing.

Plus, the fact that it can double as a brazing rod adds to its value—saving space in my toolbox. Overall, if you need reliable, high-quality aluminum rods for production or repair, this one definitely stands out in both performance and ease of use.

E4043 Aluminum Welding Rods 1 lb 1/8″ x 14″ AWS A5.3

- ✓ Excellent weldability

- ✓ Minimal spatter

- ✓ Versatile for multiple alloys

- ✕ Slightly higher price

- ✕ Best with DC power

| Alloy Composition | Aluminum-silicon alloy (AWS A5.3 Class E4043) |

| Diameter | 1/8 inch (3.2 mm) |

| Length | 14 inches (355 mm) |

| Welding Compatibility | Suitable for DCEN (DC-) power sources |

| Application Range | Welding of 1XXX, 3XXX, 4XXX, 5XXX, and 6XXX series aluminum alloys |

| Package Weight | 1 lb (0.45 kg) |

The moment I picked up this 1 lb box of E4043 aluminum welding rods, I immediately noticed how smoothly they slid into my welder’s holder. The consistency of the 1/8″ diameter is spot-on, making feeding effortless even during longer weld runs.

What really impressed me is how clean the welds looked right out of the gate. The stable arc with minimal spatter means less cleanup afterward, which is a huge time saver.

Plus, the aluminum-silicon alloy seems to handle both cast and wrought aluminum alloys with ease, so I felt confident tackling different projects.

I tested these rods on a variety of materials—from 3003 bicycle frames to marine-grade aluminum panels. The lower melting point and high ductility really helped control the puddle and prevent cracking, even on more challenging joints.

It’s also compatible with DCEN power sources, which makes it versatile for different setups.

Handling was smooth, and the flow characteristics allowed me to get a consistent, strong weld. The packaging was solid, keeping the rods protected and easy to store.

Whether you’re repairing an aluminum boat or fabricating a custom piece, these rods deliver professional results without fuss.

Overall, these rods feel like a reliable partner for anyone serious about aluminum welding. They’re a great mix of quality, ease of use, and affordability, making them a top pick for both hobbyists and pros alike.

UNIFAMILY ER4043 Aluminum Welding Rods 1/16″ x 16″ 60 pcs

- ✓ Smooth welds, no cleanup

- ✓ Stable arc, less spatter

- ✓ Durable and rust-resistant

- ✕ Limited to mild steels

- ✕ Not ideal for thick metals

| Material | High-quality aluminum ER4043 alloy |

| Diameter | 1/16 inch (1.6 mm) |

| Length | 16 inches (400 mm) |

| Quantity | 60 pieces |

| Application Suitability | Suitable for TIG welding of mild and low-alloy steels, aluminum, and various metals |

| Welding Compatibility | Compatible with standard TIG welding machines, suitable for high current welding with stable arc |

As I unwrap these UNIFAMILY ER4043 aluminum welding rods, I immediately notice their sleek, silver finish with a smooth surface that feels solid in my hand. The 16-inch length is just right, not too bulky but still manageable for various welding projects.

The rods are lightweight, which makes handling comfortable, even during longer sessions.

Once I load one into my TIG welder, I’m impressed by how smoothly it feeds through the machine. The arc stays stable, and I barely get any spatter—it’s almost like the welds just flow naturally.

No need to spend extra time cleaning up after, which definitely saves time and effort.

The ER4043 alloy handles mild steels and low-alloy metals well. I’ve used it on small automotive repairs and some sheet metal work, and the welds look clean with a consistent seam.

It’s durable and resistant to rust, so I feel confident it will last in outdoor or high-moisture environments.

What really stands out is how versatile these rods are. Whether you’re working on construction, shipbuilding, or even tanks, this pack can handle it.

Plus, the 60 pieces mean you won’t run out anytime soon, and sharing with friends or family is easy.

Overall, these rods are a reliable choice if you want smooth, strong welds without fuss. They’re simple to use, durable, and versatile enough for many projects.

For the price, they deliver excellent quality and value, making welding a much more satisfying experience.

What Are the Key Characteristics of the Best Aluminum Stick Welding Rod?

Weldability: High weldability means that the aluminum rod can be easily melted and fused to the base metal without issues such as porosity or cracking. The best rods are engineered to provide a smooth and stable arc, making them user-friendly for both beginners and experienced welders. This characteristic is vital for achieving strong and aesthetically pleasing welds.

Strength and Durability: The best aluminum stick welding rods produce welds that are not only strong but also resistant to fatigue and environmental factors. They are designed to withstand harsh conditions, making them suitable for various applications, including automotive and marine industries. Selecting a rod with high strength and durability ensures that the welded joints will maintain their integrity over time.

How Does the Composition of an Aluminum Stick Welding Rod Affect Performance?

The composition of an aluminum stick welding rod significantly influences its performance in various welding applications.

- Alloy Type: The alloy composition of the rod determines its strength, ductility, and corrosion resistance. Common alloys like 4047 and 5356 are used for different applications; for instance, 4047 is often chosen for its excellent fluidity and low melting point, making it ideal for welding thinner sections, while 5356 is preferred for its higher strength and better performance in structural applications.

- Filler Material: The filler material in the rod affects its melting characteristics and compatibility with the base metal. Rods with higher silicon content typically melt more easily and flow better into joints, while those with magnesium provide added strength and are better suited for high-stress applications.

- Coating: The coating on the welding rod plays a crucial role in the welding process by stabilizing the arc and protecting the weld pool from contamination. Different coatings can enhance the ease of use, with some designed to produce less spatter and improve overall weld appearance.

- Diameter: The diameter of the welding rod influences the heat input and deposition rate during welding. Thicker rods can provide a higher deposition rate, making them suitable for thicker materials, while thinner rods allow for more precise control in intricate welds.

- Mechanical Properties: The mechanical properties, including tensile strength and elongation, are vital for the performance of the weld. A rod that matches or exceeds the properties of the base aluminum ensures a stronger, more durable weld that can withstand the intended application’s stress and strain.

What Thickness Options are Available for Aluminum Stick Welding Rods?

When selecting aluminum stick welding rods, various thickness options are available to suit different welding applications and requirements:

- 1/16 inch (1.6 mm): This thickness is ideal for thin aluminum sections and is commonly used in projects where precision is crucial. It allows for controlled heat input, reducing the risk of warping or burn-through on delicate materials.

- 3/32 inch (2.4 mm): A versatile option, 3/32 inch rods are suitable for a broader range of aluminum thicknesses, making them popular among welders. They provide a good balance between ease of use and strength, often used in automotive and light fabrication work.

- 1/8 inch (3.2 mm): This thickness is best for welding thicker aluminum pieces, offering greater strength and stability in the weld joint. It’s often used in structural applications where durability is paramount, such as in the construction of frames and supports.

- 5/32 inch (4.0 mm): Less common, but available for specialized applications, this thickness is suited for heavy-duty welding tasks. It can handle significant material thickness and is typically used in industrial settings where strong welds are required.

- 3/16 inch (4.8 mm): This is generally reserved for very thick aluminum sections or when deep penetration is necessary. It’s often used in heavy machinery repairs or manufacturing processes that demand robust joints to withstand high stress.

Which Brands Are Considered the Best for Aluminum Stick Welding Rods?

The best brands for aluminum stick welding rods are known for their quality, performance, and reliability.

- Hobart: Hobart is a well-respected brand in the welding industry, offering aluminum stick welding rods that are known for their excellent arc stability and low spatter levels. Their rods are designed to provide a strong and durable weld, making them suitable for both amateur and professional welders.

- Lincoln Electric: Lincoln Electric is a leading manufacturer of welding equipment and consumables, including aluminum stick welding rods. Their products are recognized for their consistent quality and performance, with rods that facilitate easy handling and produce clean welds, ideal for a variety of applications.

- ESAB: ESAB provides a range of welding products, including aluminum stick welding rods that are praised for their versatility and ease of use. Their rods are engineered for high-quality aluminum welding, ensuring good penetration and a strong bond, which is particularly beneficial for structural applications.

- Forney: Forney is known for its affordable yet high-quality welding rods, including those for aluminum stick welding. Their rods are user-friendly and designed for both hobbyists and professionals, offering good performance and reliability at a competitive price point.

- AlcoTec: AlcoTec specializes in aluminum welding consumables and is recognized for its high-performance rods. Their aluminum stick welding rods are formulated to work well in various conditions, providing superior weld quality and minimizing the risk of defects in the weld.

How Do You Choose the Ideal Aluminum Stick Welding Rod for Your Project?

Choosing the ideal aluminum stick welding rod involves considering several factors that affect the quality and suitability for your specific project.

- Alloy Composition: The alloy composition of the welding rod is crucial as it affects the strength, corrosion resistance, and compatibility with the aluminum base material. Common alloys for aluminum rods include 4047 and 4045, which offer excellent fluidity and good weldability, making them suitable for various applications.

- Diameter of the Rod: The diameter of the welding rod plays a significant role in the heat input and deposition rate during welding. Thicker rods provide more filler material and are ideal for thicker sections, while thinner rods are better for precision work and lighter materials.

- Coating Type: The type of coating on the welding rod influences the arc stability and the ease of use. Coatings such as magnesium and silicon can enhance the flow of the weld pool and improve the overall finish, making it easier to achieve a strong bond.

- Welding Position: Different welding positions (flat, horizontal, vertical, overhead) can determine the best stick welding rod to use. Some rods are designed specifically for vertical or overhead applications, providing better control and reduced spatter, which is essential for achieving clean welds.

- Intended Application: The specific application for the welding project should guide your choice. For instance, if you are welding aluminum for structural purposes, a rod with higher tensile strength may be necessary, while for aesthetic applications, a rod that focuses on finish might be more appropriate.

- Ease of Use: Some rods are designed for easier use, featuring better arc stability and less spatter. If you are a beginner or working on a complicated project, selecting rods that have user-friendly characteristics can significantly benefit your welding experience.

- Manufacturer Reputation: Choosing rods from reputable manufacturers can ensure quality and reliability. Established brands often provide detailed specifications and performance data, helping you to select the best aluminum stick welding rod for your needs.

What Are Common Applications for Using Aluminum Stick Welding Rods?

Common applications for using aluminum stick welding rods include:

- Automotive Repairs: Aluminum stick welding rods are widely used in the automotive industry for repairing aluminum parts, such as engine blocks, radiators, and body panels. They provide strong, durable welds that can withstand the stress and heat generated in vehicle operation.

- Marine Applications: These rods are ideal for repairing or fabricating components in boats and other marine vessels. The corrosion resistance of aluminum makes it suitable for environments exposed to water and salt, ensuring longevity and reliability of the repairs.

- Construction and Fabrication: Aluminum stick welding rods are frequently utilized in the construction of aluminum structures, such as frames, supports, and decorative elements. Their ease of use and ability to bond aluminum effectively make them a popular choice among fabricators.

- General Maintenance and Repair: Many maintenance professionals use aluminum stick welding rods for a variety of repair tasks around facilities and workshops. These rods can be employed to fix aluminum furniture, machinery parts, and other equipment that require robust welding solutions.

- Artistic and Decorative Projects: Artists and craftsmen often use aluminum stick welding rods in their creative projects, allowing them to join aluminum pieces in unique ways. The rods enable intricate designs and sculptures that showcase the aesthetic qualities of aluminum.

What Tips Should You Follow for Effective Aluminum Stick Welding?

To achieve effective aluminum stick welding, several essential tips should be followed:

- Select the Right Welding Rod: Choosing the appropriate aluminum stick welding rod is crucial for a successful weld. The best aluminum stick welding rods are typically 4047 or 5356, as they provide excellent corrosion resistance and are suited for various aluminum alloys.

- Proper Cleaning of Aluminum Surface: Before welding, it’s vital to thoroughly clean the aluminum surface to remove any oxides, oils, or contaminants. Using a wire brush or a chemical cleaner will ensure better adhesion and penetration during the welding process.

- Adjust Welding Parameters: Adjusting the welding machine settings such as amperage and voltage is important for aluminum stick welding. Generally, a higher amperage may be required due to aluminum’s high thermal conductivity, and proper settings can prevent issues like burn-through or insufficient fusion.

- Maintain a Consistent Travel Speed: Keeping a steady travel speed while welding is essential to achieve uniform weld quality. Too fast may lead to weak welds, while too slow can cause overheating and distortion in the aluminum workpiece.

- Use the Correct Technique: Employing the right welding technique, such as a weaving or stringer bead motion, can enhance the quality of the weld. Techniques may vary based on the thickness of the aluminum and the position of the weld, so it’s important to practice and find what works best for your specific application.

- Preheat the Aluminum if Necessary: For thicker aluminum sections, preheating can help reduce the risk of cracking and improve weld penetration. This is particularly important when working with materials that have a high thermal conductivity.

How Can You Ensure Quality and Performance in Your Aluminum Stick Welding Rod?

To ensure quality and performance in your aluminum stick welding rod, consider the following factors:

- Rod Composition: The alloy composition of the welding rod greatly affects its strength and corrosion resistance. Look for rods made from 4047 or 5356 alloys, as these are commonly recognized for their excellent weldability and mechanical properties.

- Coating Quality: The coating on the welding rod plays a crucial role in the welding process. A high-quality coating ensures smooth arc starts and stability, while also preventing contamination of the weld pool, which can lead to defects.

- Diameter of the Rod: The diameter of the welding rod influences the heat input and the thickness of the material you can effectively weld. Selecting the right diameter based on your project specifications helps achieve optimal penetration and bead shape.

- Manufacturer Reputation: Choosing rods from reputable manufacturers can ensure consistent quality and performance. Established brands often provide better quality control, which translates to more reliable welding results.

- Storage Conditions: Proper storage of aluminum stick welding rods is essential to maintain their integrity. Store rods in a dry, clean environment to prevent moisture absorption, which can lead to porosity and weaken the welds.