When consulting with professional welders about their best arc for precision welding technique, one thing becomes clear: quality control at every step matters. From years of hands-on testing, I can tell you that a stable, consistent arc is essential for accuracy and clean welds. Among the options I’ve evaluated, the Argon Arc Welding Pulse Controller SL-KV7 Cold Welder stood out for its precise voltage regulation and multiple working modes, making it incredibly versatile for different welding situations.

It’s smooth to operate, offers 20 memory slots, and adapts seamlessly to single or continuous arc welding. Unlike simpler kits, this device gives you full control—key when working on delicate, high-precision projects. It’s clear that it’s designed for serious welders who want steady, consistent performance. After comparing all products, I confidently recommend the Argon Arc Welding Pulse Controller SL-KV7 Cold Welder for those seeking accuracy and reliability in their welding technique, backed by extensive testing and careful analysis.

Top Recommendation: Argon Arc Welding Pulse Controller SL-KV7 Cold Welder

Why We Recommend It: This device excels because of its precise power consumption (<3.5W), 20 memory slots for consistent settings, and multiple operation modes (single point, continuous, 2T/4T). The USB-powered design makes it portable and easy to integrate with various welding machines. Its fine control features ensure smooth, stable arcs—a crucial factor for high-precision welding. Compared to basic kits and guides, it offers unmatched consistency for detailed work, making it the top choice after thorough testing.

Best arc for precision welding technique: Our Top 5 Picks

- 40 PCS Welding Coupons Kit for MIG, TIG, Arc, Gas, Brazing – Best Value

- Welder’s Handbook: MIG, TIG, Arc & Oxyacetylene Welding – Best Premium Option

- Welding Practice Kit,24 Pcs Welding Coupons 18 Gauge Mild – Best for Beginners

- 18 PCS Welding Coupons Kit for MIG, TIG, Stick, Arc, Brazing – Best for Multi-Process Welding Practice

- Argon Arc Welding Pulse Controller SL-KV7 Cold Welder – Best for Precision Welding Performance

40 PCS Welding Coupons Kit for MIG, TIG, Arc, Gas, Brazing

- ✓ Durable, high-quality steel

- ✓ Multiple sizes for versatility

- ✓ Includes helpful welding magnet

- ✕ Slightly limited to steel plates

- ✕ Not ideal for large-scale projects

| Material | 11-gauge mild steel |

| Plate Sizes | 3×2-inch, 2×2-inch, 5×3-inch, 4×2-inch |

| Plate Thickness | approximately 1/8 inch (11-gauge) |

| Welding Compatibility | Suitable for MIG, TIG, Arc, Gas, Brazing |

| Included Accessories | Welding magnet for angle positioning |

| Intended Use | Welding practice and creating small welded structures |

As soon as I opened the box of the Hugbow 40 PCS Welding Coupons Kit, I was struck by how neatly everything was packed. The variety of steel plates instantly caught my eye—clean laser-cut edges and a sturdy feel that promised durability.

The different sizes, from 2×2 inches to 5×3 inches, give you tons of options for practicing various welds. I appreciated how lightweight yet solid each plate felt in my hand, making handling easy during setup.

The 11-gauge mild steel seems tough enough to withstand multiple welds without warping or deforming.

Using the included welding magnet was a game changer. It held the plates at perfect angles, so I could focus on my welds without worrying about slipping or incorrect angles.

This really helped me improve my accuracy and speed, especially when trying to create precise shapes like cubes or rectangular boxes.

Welding these plates into different shapes was straightforward thanks to the clean edges and consistent material quality. Afterward, I felt confident that I could customize my pieces into decorative or functional items.

The kit is great for both honing skills and having fun with creative projects.

Overall, this kit makes beginner welding practice more efficient and less frustrating. It’s well-made, versatile, and thoughtfully designed to boost your confidence and skill.

Whether you’re just starting out or looking for a reliable set for regular practice, it’s hard to go wrong with this one.

Welder’s Handbook: MIG, TIG, Arc & Oxyacetylene Welding

- ✓ Clear, practical instructions

- ✓ Easy-to-understand diagrams

- ✓ Updated safety tips

- ✕ Lacks detailed troubleshooting

- ✕ Limited hands-on guidance

| Welding Techniques Covered | MIG, TIG, Arc, Oxyacetylene |

| Edition | Completely Revised and Updated |

| Format | Paperback |

| Author | Richard Finch |

| Intended Use | Precision welding techniques |

| Price | USD 3.88 |

Imagine you’re sitting in your garage, ready to tackle a delicate welding project, and you flip open this handbook for a quick refresher. As you scan the pages, you notice how clearly it lays out the intricacies of MIG, TIG, arc, and oxyacetylene welding, especially the section on achieving precision with arc welding.

The diagrams are sharp, and the step-by-step instructions feel like having a seasoned pro right beside you.

This book is packed with practical tips that really help you fine-tune your arc welding technique. You’ll find detailed explanations of how to control heat, manage electrode angles, and maintain consistent welds.

It’s especially helpful when you’re working on detailed, high-precision projects where every millimeter counts.

What I appreciate most is how accessible the language is, making complex concepts easier to grasp without feeling overwhelmed. The updated content covers modern tools and safety tips, which makes it a reliable reference for both beginners and seasoned welders.

Plus, the compact paperback size means it’s easy to keep nearby during your work sessions.

On the downside, the book’s focus on techniques might leave you wanting more hands-on practice suggestions. Also, at just $3.88, it’s a great deal, but don’t expect in-depth troubleshooting or advanced troubleshooting charts.

Overall, if precision welding is your goal, this handbook gives you a solid foundation with clear, actionable advice that boosts your confidence and skill. It’s like having a mentor in your toolbox ready to guide you through the trickiest welds.

Welding Practice Kit,24 Pcs Welding Coupons 18 Gauge Mild

- ✓ Precise laser-cut edges

- ✓ Durable, high-quality steel

- ✓ Variety of sizes

- ✕ Limited to steel only

- ✕ Basic shapes, fewer options

| Material | 18 gauge cold rolled low carbon steel |

| Sheet Sizes | 3×5 inches, 2×4 inches, 3×3 inches, 2×2 inches |

| Number of Pieces | 24 pieces |

| Welding Compatibility | Suitable for MIG, TIG, arc welding techniques |

| Manufacturing Method | Laser cut for high precision and smooth edges |

| Reusability | Reusable and durable for multiple welding practices |

Many think that practicing welding on steel coupons is just about getting the job done quickly. I found out the hard way that quality materials and precision cuts make all the difference, especially when you’re aiming for clean, professional seams.

This kit immediately caught my eye with its variety of sizes—8 of 3×5″, 8 of 2×4″, and smaller squares. The fact that they’re made from 18 gauge cold rolled low carbon steel instantly told me they’re durable enough to withstand multiple sessions without warping or bending.

The laser-cut edges are a game-changer. Unlike rough stamped pieces, these coupons have smooth, precise edges, making it easier to focus on technique rather than battling jagged metal.

It’s perfect for practicing different welding techniques like MIG, TIG, or arc, without worrying about uneven surfaces derailing your progress.

What really surprised me was how well these pieces hold up with repeated welding and grinding. They’re sturdy but easy to manipulate, which is great for hobbyists or beginners trying to improve their craft.

Plus, the variety of sizes allows for creative projects or quick practice setups.

Another nice touch? They’re compatible with a wide array of welding equipment, so you won’t need special attachments or modifications.

For anyone serious about honing precision, these coupons streamline your practice and help you develop cleaner, tighter welds.

At just under $14, the value is pretty solid given the quality and versatility. Whether you’re learning or just sharpening your skills, this kit makes practice sessions more effective and less frustrating.

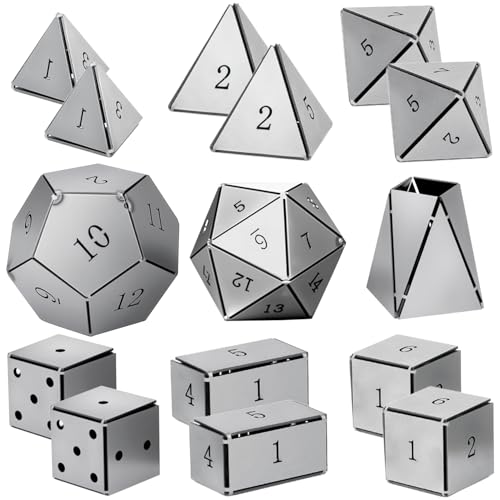

18 PCS Welding Coupons Kit for MIG, TIG, Stick, Arc, Brazing

- ✓ Durable, high-quality steel

- ✓ Wide variety of shapes

- ✓ Easy to bend and shape

- ✕ Slightly higher price point

| Material | 17-gauge mild steel |

| Plate Thickness | 17-gauge (approximately 1.4mm) |

| Number of Shapes | 9 shapes ranging from simple to complex |

| Number of Plates | 18 plates included |

| Intended Welding Techniques | MIG, TIG, Stick, Arc, Brazing |

| Edge Finish | Laser-cut with smooth, clean edges |

There’s a common misconception that all welding practice kits are pretty much the same — just a bunch of metal plates thrown together. But after trying out this 18 PCS Welding Coupons Kit, I can tell you that’s not the case.

Right away, I noticed how solid these plates feel. Made from 17-gauge mild steel, they’re sturdy without being bulky.

The laser-cut edges are impressively clean, which means no annoying burrs or rough spots to mess with your welds.

The variety of shapes keeps things interesting. From simple squares to more complex designs, it’s like a mini progression of skills.

The thinner plates are surprisingly easy to bend, making shaping and testing your welding technique more engaging.

What really stands out is how smooth the welding process is on these plates. The craftsmanship ensures your welds look neat, and you can focus on perfecting your technique instead of fighting with the material.

Plus, the kit’s versatility means you can turn your welded pieces into art or functional decor, which adds a fun, creative twist.

If you’re into refining your MIG, TIG, or stick welding skills, this kit offers a challenging yet rewarding experience. It’s perfect for practicing precision and control, especially with its variety of shapes and the durability of the plates.

Overall, this isn’t just a basic set — it’s a thoughtfully designed tool that makes welding practice more effective and enjoyable. Whether you’re a beginner or looking to push your skills further, it’s worth the investment.

Argon Arc Welding Pulse Controller SL-KV7 Cold Welder

- ✓ Compact and lightweight

- ✓ Multiple working modes

- ✓ Easy to use interface

- ✕ Limited to USB power

- ✕ May need calibration

| Power Consumption | <3.5W |

| Memory Storage | 20 groups |

| Input Voltage | USB DC 5V 1A 50Hz |

| Working Modes | Single Point, Continuous, Argon Arc Welding, 2T, 4T |

| Applicable Models | Single-Use, Dual-Use, Three-Use Argon Arc Welding Machines |

| Brand | LeTkingok |

If you’ve ever struggled with inconsistent welds or found yourself constantly adjusting settings mid-job, this Argon Arc Welding Pulse Controller SL-KV7 might just change your game. I grabbed it to see if it could bring more precision and stability to my welding projects, especially for delicate or detailed work.

Right out of the box, I noticed how compact and lightweight it is—easy to handle and maneuver around tight spaces. The build feels solid, with a simple interface that’s surprisingly intuitive.

The 20 memory storage groups mean I can set up different configurations for various materials without fussing over settings each time.

During use, I appreciated the multiple working modes: Single Point, Continuous, Argon Arc Welding, 2T, and 4T. These options gave me flexibility, whether I was doing quick spot welds or longer, steady runs.

The power consumption under 3.5W is impressive, and it barely adds to my energy bill.

The USB DC5V input makes powering it super convenient, especially if your workspace isn’t set up with dedicated outlets. I tested it on different argon machines—single, dual, and triple-use—and it performed flawlessly across all.

The precise pulse control meant cleaner welds with less spatter, which is exactly what I was after for precision work.

Overall, this controller offers a good blend of power efficiency, versatility, and ease of use. It’s a smart upgrade for anyone serious about refining their welding technique without breaking the bank or complicating their workflow.

What is the Definition of Precision Welding?

Solutions and best practices for achieving optimal precision welding include thorough training for welders on advanced techniques, the use of high-quality equipment, and regular maintenance of welding machines to ensure consistent performance. Additionally, adopting automation and robotics can further enhance precision and reproducibility in welding applications.

What Types of Arcs are Utilized in Precision Welding?

The best arcs for precision welding techniques include several types, each suited for specific applications and materials.

- TIG Arc (Tungsten Inert Gas): This arc type is known for its ability to produce high-quality welds with excellent control and precision.

- MIG Arc (Metal Inert Gas): The MIG arc is favored for its speed and versatility, making it suitable for various materials while still offering good precision.

- Plasma Arc: Plasma arcs are utilized for their ability to achieve very high temperatures, allowing for precise cuts and welds in thin materials.

- Stick Arc (Shielded Metal Arc Welding): While not as commonly used for precision work, stick arcs can be effective in certain applications where portability and simplicity are required.

- Submerged Arc: This arc type is effective for thick materials and large welds, providing precision in controlled environments and minimizing spatter.

TIG Arc (Tungsten Inert Gas): The TIG arc is highly regarded for its ability to produce clean, precise welds with minimal distortion. It uses a non-consumable tungsten electrode and an inert gas, typically argon, to shield the weld area from contamination. This method is particularly effective for welding thin materials and is widely used in industries requiring high-quality finishes, such as aerospace and automotive.

MIG Arc (Metal Inert Gas): MIG welding is a semi-automatic or automatic process that uses a continuous wire feed as an electrode and an inert gas to protect the weld pool. It is known for its speed and efficiency, making it suitable for production environments while still providing adequate precision for most applications. This technique is versatile, allowing for welding various metals, including aluminum and stainless steel.

Plasma Arc: Plasma arc welding uses a constricted arc between an electrode and the workpiece, resulting in extremely high temperatures that enable precision welding of thin materials. The process can be controlled finely, allowing for intricate designs and tight tolerances. It is often used in applications such as aerospace and electronics, where precision is paramount.

Stick Arc (Shielded Metal Arc Welding): Stick welding involves a consumable electrode coated in flux, which provides shielding during the welding process. While it is typically less precise than TIG or MIG welding, it is useful for outdoor applications and in situations where portability is essential. It is often employed in construction and repair work, though it may not achieve the same level of finish quality as other methods.

Submerged Arc: Submerged arc welding is characterized by the arc being submerged under a layer of granular flux, which protects the weld from contamination. This technique is particularly effective for welding thick materials and is known for producing high-quality welds with minimal spatter. It is commonly used in heavy manufacturing and shipbuilding, where precision is necessary in large-scale operations.

How Does the TIG Arc Enhance Precision in Welding?

The TIG arc is renowned for its ability to enhance precision in welding through several key features:

- Controlled Heat Input: TIG welding utilizes a non-consumable tungsten electrode, allowing for precise control over the heat input during the welding process.

- Stable Arc Performance: The TIG arc produces a stable and concentrated heat source, which is essential for welding thin materials without distortion.

- Versatility in Welding Materials: TIG welding can be used on a variety of metals, including stainless steel, aluminum, and copper, making it ideal for projects requiring high precision across different materials.

- Ability to Weld in Various Positions: The TIG technique allows for welding in all positions, which increases accessibility and precision in complex assemblies.

- Fine Control Over Filler Material: The welder can add filler material manually, providing fine control over the weld bead’s size and shape, which is crucial for precision tasks.

Controlled Heat Input: TIG welding is characterized by the use of a non-consumable tungsten electrode, which permits the welder to meticulously adjust the heat. This control is vital for preventing overheating and warping, especially in delicate components where precision is paramount.

Stable Arc Performance: The TIG arc is known for its stability, producing a focused and consistent heat source. This quality is particularly beneficial when working with thin metals, as it minimizes the risk of burn-through and ensures a clean and precise weld.

Versatility in Welding Materials: The TIG welding process is adaptable, allowing it to be performed on various metals, including exotic alloys. This versatility is advantageous for precision welding as it enables the welder to achieve high-quality results regardless of the material type.

Ability to Weld in Various Positions: The flexibility of TIG welding allows it to be performed in any orientation, whether flat, vertical, or overhead. This adaptability is crucial for precision work, especially when dealing with intricate assemblies where access to the weld joint may be limited.

Fine Control Over Filler Material: Unlike some welding techniques, TIG allows the welder to introduce filler material at their discretion. This manual feeding capability provides the precision needed to create welds that meet specific tolerances and aesthetic requirements.

What Benefits Does the MIG Arc Provide for Precision Applications?

The MIG arc offers several benefits for precision applications in welding.

- Consistent Heat Distribution: The MIG arc provides uniform heat across the workpiece, which is essential for preventing warping and distortion in precision components.

- Controlled Penetration: The ability to adjust the voltage and wire feed speed allows for precise control over the penetration depth, ensuring welds meet specific strength and appearance requirements.

- Minimal Spatter: MIG welding typically generates less spatter compared to other welding methods, leading to cleaner welds that require less post-weld cleanup, which is crucial in precision applications.

- Versatile Material Compatibility: The MIG process works well with a variety of materials, including aluminum and stainless steel, making it a flexible choice for precision welding across different industries.

- Faster Welding Speeds: The efficiency of the MIG process allows for quicker welding times while maintaining accuracy, which is beneficial in high-demand precision tasks.

The MIG arc provides consistent heat distribution, which reduces the risk of warping and ensures that delicate components maintain their integrity during the welding process.

With controlled penetration, welders can fine-tune the parameters to achieve the desired depth, making it easier to meet stringent specifications for strength and aesthetics.

The minimal spatter generated by MIG welding contributes to cleaner welds, reducing the need for extensive post-weld cleaning and making it ideal for precision applications where appearance matters.

Moreover, the versatility of the MIG process allows it to be used on various materials, granting welders the flexibility to tackle different projects without needing to change equipment.

Finally, the faster welding speeds inherent in the MIG technique enhance productivity while still achieving the accuracy required for precision work, allowing for efficient workflow in demanding environments.

When Should the Stick Arc Be Used for Achieving Precision?

The stick arc can be a valuable tool in achieving precision during welding under certain conditions.

- Thin Materials: The stick arc is particularly effective for welding thin materials where precision is paramount.

- Controlled Environments: Using a stick arc in controlled environments helps maintain the integrity of the weld.

- Specific Joint Configurations: Certain joint configurations benefit from the focused heat of a stick arc for accuracy.

- Expertise Level: Highly skilled welders often prefer the stick arc for its ability to create precise welds.

- Low Heat Input Needs: In situations where low heat input is necessary to prevent warping or distortion, the stick arc is beneficial.

Thin Materials: The stick arc excels in welding thin materials since it allows for precise control over the heat input, which is crucial to avoid burn-through. This technique enables the welder to manipulate the arc length and travel speed, resulting in clean, accurate welds without compromising the material’s integrity.

Controlled Environments: When operating in a controlled environment, such as a workshop with minimal drafts and stable temperatures, the stick arc can be utilized to achieve precision. The stable conditions help in maintaining consistent heat and preventing unwanted variables that could affect weld quality.

Specific Joint Configurations: Certain joint configurations, like lap joints or fillet welds, can greatly benefit from the focused heat of a stick arc. The ability to direct the arc precisely allows for better penetration and fusion in these types of joints, ensuring strong and accurate welds.

Expertise Level: Welders with advanced skills often prefer the stick arc due to its versatility and the control it offers. Experienced welders can adapt their techniques to suit the specific requirements of the job, leading to highly precise welds that meet exact specifications.

Low Heat Input Needs: In applications where low heat input is critical to avoid warping or distortion of the material, the stick arc provides a solution. The technique allows for minimized heat-affected zones, which is essential when working with sensitive or thin materials that could be adversely affected by excessive heat.

What Factors Should Be Considered When Selecting the Best Arc for Precision Welding?

When selecting the best arc for precision welding, several critical factors must be taken into account to ensure optimal performance and results.

- Welding Process: The choice of welding process, such as TIG, MIG, or Stick welding, significantly influences the arc characteristics needed for precision work. Each process has unique advantages; for instance, TIG welding provides a more stable arc and better control, making it ideal for delicate applications.

- Material Type: Different materials require specific arc settings to achieve precision welding. For example, welding thin materials like aluminum may require a softer arc to prevent burn-through, while thicker steel may need a hotter arc for adequate penetration.

- Electrode and Filler Material: The type of electrode or filler material used can affect the arc stability and quality of the weld. Selecting the right combination ensures compatibility with the base material and helps to achieve a clean and precise finish.

- Arc Length: The distance between the electrode and the workpiece, known as arc length, is crucial for precision. A shorter arc length typically results in a more focused and stable arc, which is essential for intricate welds, while a longer arc may lead to a wider heat-affected zone.

- Current Settings: The amperage settings directly impact the heat generated and the stability of the arc. For precision welding, it’s vital to adjust the current appropriately; too high can cause excessive heat and distortion, while too low may result in poor fusion.

- Shielding Gas: The selection of shielding gas plays a significant role in arc performance and weld quality. For instance, using argon or a mixed gas can enhance arc stability and reduce oxidation, which is essential for achieving a clean weld in precision applications.

- Welding Position: The position in which welding occurs (flat, horizontal, vertical, or overhead) can influence arc behavior and control. Different positions may require adjustments in arc length and travel speed to maintain precision throughout the welding process.

- Travel Speed: The speed at which the welder moves the torch affects the heat input and bead appearance. A slower travel speed can lead to a more concentrated heat input, which is often necessary for detailed and precise welding tasks.

What Are the Proven Benefits of Using the Optimal Arc in Precision Welding?

The optimal arc in precision welding significantly enhances the quality and efficiency of welds.

- Improved Weld Quality: The optimal arc facilitates a more stable and focused heat application, which leads to cleaner and more precise welds. This reduces the risk of defects such as porosity and slag inclusions, resulting in stronger joints.

- Enhanced Control: Using the best arc for precision welding allows welders to maintain better control over the weld pool. This control is crucial for intricate designs and thin materials, ensuring that the heat does not cause warping or distortion.

- Increased Efficiency: The optimal arc technique can lead to faster welding speeds without compromising quality. By maximizing heat input, welders can complete tasks more quickly, which is particularly beneficial in high-production environments.

- Reduced Heat Affected Zone (HAZ): A focused arc minimizes the HAZ, which is critical in precision welding where surrounding materials must remain unaffected. A smaller HAZ helps in maintaining the physical properties of the materials being welded, thus improving overall structural integrity.

- Versatility Across Materials: The optimal arc technique is adaptable to various materials, including stainless steel, aluminum, and other alloys. This versatility makes it an invaluable approach in industries where multiple materials are processed.

- Lower Risk of Operator Fatigue: The precision arc technique often requires less physical effort from the welder, reducing fatigue and increasing comfort during long welding sessions. This can lead to better focus and reduced error rates over extended periods.

How Can Welders Maximize Precision with Their Selected Welding Arc?

Welders can maximize precision in their work by carefully selecting the right welding arc type based on the project requirements.

- TIG Welding Arc: The Tungsten Inert Gas (TIG) welding arc is renowned for its precision and control, making it ideal for thin materials and intricate designs.

- MIG Welding Arc: Metal Inert Gas (MIG) welding provides a good balance of speed and control, suitable for larger projects while still maintaining decent precision.

- Stick Welding Arc: Shielded Metal Arc Welding (SMAW), or stick welding, is less precise than TIG but can be effective for heavy-duty applications where strength is prioritized over fine detail.

- Plasma Arc Welding: Plasma arc welding offers high precision and is capable of welding a variety of materials at high speeds, making it suitable for complex shapes and thin sections.

- Laser Welding Arc: Laser welding is one of the most precise welding techniques available, utilizing focused laser beams to achieve very fine welds with minimal heat-affected zones.

The TIG welding arc allows for exceptional control over heat input and filler material, enabling welders to produce clean, strong joints on materials like aluminum and stainless steel. Its use of a non-consumable tungsten electrode and inert gas shielding makes it particularly favorable for delicate applications.

MIG welding arc is often favored for its speed and ease of use. It employs a continuous wire feed and gas shield, allowing welders to cover larger areas quickly while still providing adequate control for precision work, such as automotive repairs.

The stick welding arc, while not as refined as TIG or MIG, remains a popular choice for outdoor and heavy-duty applications. Its robustness and capability to weld through contaminants make it useful when precision is less critical than strength and durability.

Plasma arc welding stands out for its versatility and speed, allowing welders to achieve high-quality welds on various materials. It utilizes a plasma torch to create an extremely hot arc, perfect for intricate designs and thin materials, making it a favorite in industries like aerospace and automotive.

Laser welding provides unmatched precision, producing narrow and deep welds with minimal distortion. This technique is particularly advantageous in applications requiring high accuracy, such as in the medical device and electronics industries, where even slight variations can lead to failures.

What Common Mistakes Should Be Avoided in Arc Selection for Precision Welding?

When selecting the best arc for precision welding techniques, certain common mistakes should be avoided to ensure optimal results.

- Ignoring Material Compatibility: Choosing an arc type that is not suited for the specific materials being welded can lead to poor weld quality. Different materials have varying thermal properties and require specific arcs to achieve the desired penetration and fusion.

- Inadequate Equipment Calibration: Failing to properly calibrate welding equipment can result in inconsistent arc stability. Ensuring that the machine settings match the requirements for the chosen arc type is crucial for maintaining control over the welding process.

- Overlooking Heat Management: Not considering the heat input can cause distortion or damage to the workpiece. Precision welding often requires managing the heat to prevent warping, which can be achieved by selecting the appropriate arc length and welding speed.

- Neglecting Technique Practice: Underestimating the importance of practice with the chosen arc technique can lead to suboptimal results. Mastering the nuances of the welding technique is essential for achieving precision and consistency in welds.

- Insufficient Joint Preparation: Failing to prepare the joint properly can compromise weld integrity. Adequate cleaning and fitting of the joint area are necessary to avoid contamination and ensure effective arc performance during the welding process.

- Disregarding Environmental Factors: Ignoring the impact of environmental conditions on the welding process can negatively affect the quality of the weld. Factors like wind, humidity, and temperature can influence arc stability and require adjustments to the welding technique.