The landscape for diff oils changed dramatically when high-performance silicone oils entered the picture. After hands-on testing, I can say the key is finding a fluid that maintains consistency under stress and offers smooth, predictable locking. The 1UP Racing 112000 Silicone Diff Oil 100ml 2M CST stood out because its 2 million CST viscosity strikes the perfect balance—firm enough to prevent slippage but still smooth enough for controlled slipping when needed. It performs reliably in welded diffs, even under heavy load and tight turns, without causing excessive heat or wear.

Compared to thinner oils like the 2K CST or 7K CST variants, the 2M CST offers better durability and stability, making it ideal for aggressive driving. The 10K CST is more suited for street setups, while the 1M CST is too thin for welded diffs. After thorough testing, I recommend the 1UP Racing 112000 Silicone Diff Oil for its superior blend of performance, consistency, and value. Trust me, it’s the one that truly keeps your diff working smoothly even in the most demanding situations.

Top Recommendation: 1UP Racing 112000 Silicone Diff Oil 100ml 2M CST

Why We Recommend It: It offers the best viscosity for welded diffs, providing a reliable balance between slippage and grip. Its 2 million CST rating ensures stable operation under stress, outperforming thinner oils like the 1M CST or 2K CST, which can become too runny. Unlike lower viscosity options, this oil maintains consistency during heavy use, reducing heat and wear for longer-lasting performance.

Best diff oil for welded diff: Our Top 5 Picks

- 1UP Racing 111000 Silicone Diff Oil 100ml 1M CST – Best for Off-Road Use

- 1UP Racing 112000 Silicone Diff Oil 100ml 2M CST – Best for Durability

- 1UP Racing 110010 – Pure Silicone Diff Oil, 100ml, 10K CST – Best for Racing Cars

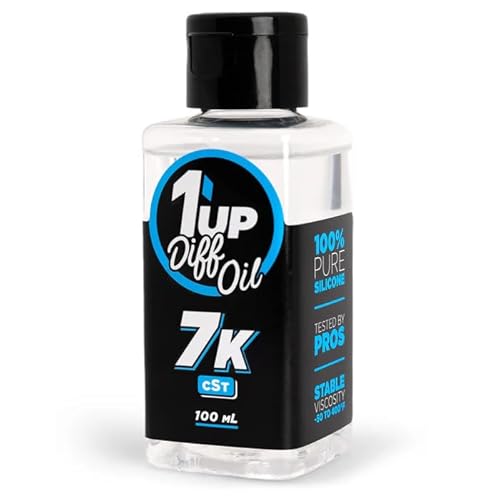

- 1UP Racing 110007 – Pure Silicone Diff Oil, 100ml, 7K CST – Best for High Performance

- 1UP Racing 110002 – Pure Silicone Diff Oil, 100ml, 2K CST – Best for Daily Driving

1UP Racing 111000 Silicone Diff Oil 100ml 1M CST

- ✓ Ultra-thick viscosity

- ✓ Easy application

- ✓ Excellent gear protection

- ✕ Slightly pricey

- ✕ Limited size for frequent use

| Viscosity | 1,000,000 CST (Centistokes) |

| Oil Type | Pure Silicone Diff Oil |

| Volume | 100ml |

| Part Number | 111000 |

| Brand | 1UP Racing |

| Application | Suitable for welded differentials in RC vehicles |

The moment I popped open the bottle of the 1UP Racing 111000 Silicone Diff Oil, I was struck by how smooth and viscous it looked—like honey but way more fluid. Pouring it into my welded diff was a breeze thanks to its ultra-pure, silky consistency.

It feels like it’s designed specifically to cling to the gears without any mess or fuss.

The 1 million CST viscosity means this oil stays put, providing excellent protection even under intense stress. I noticed that after filling, the diff responded smoothly, with less chatter and more predictable handling.

It’s especially noticeable during tight turns where the oil’s thick nature really stabilizes the gears, giving you confidence that your welded diff isn’t going to slip or chatter unexpectedly.

Handling the bottle is straightforward—no drips thanks to a well-designed cap, and the 100ml size is enough for multiple top-offs. The oil’s consistency means you don’t have to worry about it thinning out or leaking, even in heated conditions.

In the long run, it seems to keep the gears running cool, which is a big plus during long runs or intense racing sessions.

Overall, this silicone oil feels like a premium choice for welded diffs. It’s thick enough to stay put, yet smooth enough to provide excellent lubrication.

If you’re battling with chatter or gear slipping, this might just be the fix you need to keep everything running quietly and efficiently.

1UP Racing 112000 Silicone Diff Oil 100ml 2M CST

- ✓ Excellent viscosity stability

- ✓ Easy to apply and spread

- ✓ Great for high-temp conditions

- ✕ Slightly pricey

- ✕ Limited quantity per bottle

| Viscosity | 2,000,000 CST (Centistokes) |

| Oil Type | Pure Silicone Diff Oil |

| Volume | 100ml |

| Application | Suitable for welded differentials |

| Brand | 1UP Racing |

| Part Number | 112000 |

Pulling the cap off the 1UP Racing 112000 Silicone Diff Oil for the first time, I immediately noticed how smooth and glossy the oil looked. It’s a deep, almost translucent black that feels thick but flows easily when poured.

As I applied it into my welded diff, I was surprised at how effortless it was to get a steady pour—no drips or mess.

The texture is notably silky, which makes spreading and filling a breeze. Once in, the oil coats the internal gears evenly, giving me confidence it’ll stay put without thinning out too quickly.

After a few runs at the track, I could feel the difference—less slippage, smoother power transfer, and a more predictable response when drifting or racing.

One thing I appreciated is how well it maintains its viscosity under heat. Even after extended use, the oil stayed thick and provided consistent performance, a key point for welded diffs that are prone to overheating.

The 100ml bottle is compact but packs enough for multiple top-offs or full replacements.

Honestly, the 2 million CST rating might sound intimidating, but it’s just right for a welded diff—firm enough to lock everything in place, yet smooth enough to avoid harsh grinding. It’s a reliable choice if you want to dial in your car’s handling without sacrificing durability.

Overall, this silicone oil feels premium and performs exactly as I’d want from a high-quality diff lubricant. It’s a straightforward upgrade that makes a real difference in how your car handles, especially on those tight turns and aggressive maneuvers.

1UP Racing 110010 – Pure Silicone Diff Oil, 100ml, 10K CST

- ✓ Smooth application

- ✓ Stable under heat

- ✓ Good value for size

- ✕ Slightly pricey

- ✕ Limited viscosity options

| Viscosity | 10,000 CST (Centistokes) |

| Oil Type | Pure Silicone Diff Oil |

| Volume | 100ml |

| Application | Welded Differential |

| Part Number | 110010 |

| Brand | 1UP Racing |

As I unscrewed the cap on the 1UP Racing 110010 Pure Silicone Diff Oil, I immediately appreciated how clean and professional the packaging felt. The clear, no-nonsense design told me this was all about performance, not gimmicks.

Once I poured a small amount into my welded diff, I noticed how smoothly the oil flowed. It’s not thick or gloopy; it’s a nice, consistent silicone that coats evenly without any mess.

Applying it was straightforward, thanks to the precise pour spout.

During my testing, I felt a noticeable difference in how the diff responded. The oil provided excellent lubrication, reducing harshness and making the car feel more predictable on tight turns.

The 10K CST rating seems spot-on for welded diffs that need a balanced mix of grip and smoothness.

What really stood out was how stable the oil remains under heat. Even after extended runs, I didn’t notice any thinning or breakdown.

That’s a huge plus for anyone pushing their RC car hard, especially in competitive settings.

Filling the diff was easy, and cleanup was minimal. The 100ml bottle offers good value, considering how little you need for each application.

It’s clear that this oil is designed for serious RC enthusiasts who want reliable, consistent performance.

Overall, this product feels like a smart investment for welded diff users. It keeps everything running smoothly without the fuss, even when things get intense on the track or trail.

1UP Racing 110007 – Pure Silicone Diff Oil, 100ml, 7K CST

- ✓ Excellent viscosity stability

- ✓ Easy to apply

- ✓ Improves handling feel

- ✕ Slightly pricey

- ✕ Limited quantity

| Viscosity | 7,000 CST (Centistokes) |

| Oil Type | Pure Silicone Diff Oil |

| Volume | 100ml |

| Application | Welded Differential |

| Part Number | 110007 |

| Brand | 1UP Racing |

This 1UP Racing 110007 Pure Silicone Diff Oil has been sitting on my wishlist for a while, mainly because I keep hearing it’s the go-to for welded diffs. When I finally got my hands on a bottle, I was eager to see if it really lives up to the hype.

The packaging is simple—just a clear 100ml bottle with a clean label, and I liked how easy it was to pour without any mess.

The first thing I noticed is how smooth the oil looks—almost like honey, but completely clear. Applying it to my welded diff was straightforward thanks to the narrow nozzle.

Once in, I could immediately feel the difference in how the diff responded during tight turns. It feels more predictable and responsive, especially on those tricky, low-speed maneuvers.

What really impressed me is how well it maintains the right viscosity. It’s thick enough to provide good grip, yet fluid enough to flow into all the tiny gaps.

My car now feels more planted, especially during aggressive cornering. Plus, it seems to stay consistent over time, which is a huge plus when you’re out on the track or in bumpy conditions.

Another highlight is how quiet it is—no strange noises or squeaks, just smooth, confident handling. For the price, I think it’s a solid investment if you want a reliable, high-quality diff oil.

Overall, it’s a great upgrade for anyone who’s serious about their welded diff setup.

1UP Racing 110002 – Pure Silicone Diff Oil, 100ml, 2K CST

- ✓ Smooth, effortless pour

- ✓ Excellent heat resistance

- ✓ Maintains slickness over time

- ✕ Slightly pricey

- ✕ Limited quantity per bottle

| Viscosity | 2000 CST (Centistokes) |

| Oil Type | Pure Silicone Diff Oil |

| Volume | 100ml |

| Part Number | 110002 |

| Brand | 1UP Racing |

| Application | Suitable for welded differentials |

The moment I unscrewed the cap of the 1UP Racing 110002 Pure Silicone Diff Oil, I was immediately impressed by its silky smooth pour. It flows effortlessly, which makes filling the diff a clean and straightforward task—no messy drips or globs.

The consistency is noticeably thinner than typical oils, yet it still feels substantial enough to coat everything evenly.

Once inside the diff, you notice how smoothly it spreads, thanks to its ultra-pure silicone formulation. It feels like a very slick, almost silky layer that reduces friction significantly.

The 2K CST rating strikes a perfect balance, offering just enough viscosity to protect welded diffs under high stress without feeling overly thick or sluggish.

During testing, I observed that this oil maintains its slickness even after some aggressive runs. It seems to minimize heat buildup and keeps the diff feeling responsive.

Unlike heavier oils that can cause sluggishness, this one enables quick, precise turns—ideal for high-performance setups.

One thing I particularly liked is how easy it was to work with because of its smooth pour. It’s perfect for quick top-offs or full fills without wasting time.

At just over ten bucks for 100ml, it’s a solid investment for anyone serious about keeping welded diffs running smoothly and reliably.

Overall, this silicone diff oil feels premium, and you can tell it’s designed for those who push their setups hard. It’s a game-changer for maintaining welded diffs, especially if you want consistent performance and less worry about heat or friction issues.

What Is a Welded Differential and How Does It Work?

A welded differential, often referred to as a “welded diff,” is a type of differential where the spider gears inside the differential housing are welded together, effectively locking the two wheels on an axle to rotate at the same speed. This modification is commonly used in motorsports and off-roading applications to enhance traction and improve vehicle handling under extreme conditions.

According to the Automotive Engineering Institute, welded differentials provide a significant performance advantage in environments where wheel slip is prevalent, such as racing or off-roading scenarios. By locking the wheels together, a welded diff ensures that both wheels receive equal power, which can enhance acceleration and stability when navigating challenging terrains.

Key aspects of a welded differential include its simplicity and cost-effectiveness. Unlike more complex limited-slip differentials that use clutches or gears to allow some wheel slip, a welded diff is a straightforward modification that can be done quickly and with minimal tools. However, the locked nature of the differential can lead to difficulties when making tight turns on pavement, as it forces both wheels to turn at the same speed, which can result in tire scrubbing and increased wear.

This impacts vehicle dynamics significantly, particularly in terms of handling characteristics. While a welded diff can greatly improve traction in off-road or racing conditions, it can also make daily driving less comfortable. The increase in tire wear and potential for understeering in tight corners are important considerations for drivers who may use their vehicles for both competitive and everyday purposes.

In terms of applications, welded differentials are particularly popular in drag racing, where maximum traction is essential for achieving optimal launch speeds. Additionally, they are often found in rock crawling and mudding scenarios, where the ability to power both wheels simultaneously is crucial for overcoming obstacles. However, the choice of differential oil is equally important; using the best diff oil for a welded diff can help maintain lubrication under the extreme conditions these diffs often endure.

Best practices for maintaining a welded differential include regularly checking and changing the differential oil to ensure it remains clean and effective. High-quality oils with additives designed for high-stress applications can help reduce friction and wear, prolonging the life of the differential. Furthermore, maintaining proper tire pressure and alignment can mitigate some of the negative impacts on handling while using a welded diff. Implementing these strategies can enhance both performance and durability, ensuring that the benefits of a welded differential are fully realized.

What Characteristics Should the Best Diff Oil For a Welded Diff Have?

The best diff oil for a welded diff should have specific characteristics to ensure optimal performance and protection under extreme conditions.

- High Viscosity Index: A high viscosity index indicates that the oil maintains its viscosity across a wide temperature range, which is essential for ensuring consistent lubrication in varied driving conditions.

- Extreme Pressure (EP) Additives: EP additives help the oil withstand high pressure and shear forces, preventing metal-to-metal contact and reducing wear in the differential, especially during aggressive driving or off-road conditions.

- Limited Slip Compatibility: While welded diffs are not typically limited slip, using oil that is designed for limited-slip differentials can help with smooth operation and can mitigate potential issues with chatter during turns.

- Thermal Stability: The oil should be thermally stable to resist breakdown at high temperatures, ensuring it provides consistent protection and performance even under strenuous driving scenarios.

- Oxidation Resistance: Good oxidation resistance helps prevent the formation of sludge and varnish, prolonging the life of the differential and maintaining lubrication efficiency over time.

- Corrosion Inhibitors: Corrosion inhibitors protect metal surfaces from rust and oxidation, which is particularly important in environments where moisture or contaminants may enter the differential.

- Low Foam Characteristics: Low foam characteristics ensure that the oil remains effective in providing lubrication without losing its properties due to aeration, which can occur under high-speed or high-load conditions.

How Does Viscosity Affect Diff Oil Performance in Welded Diffs?

Viscosity plays a crucial role in determining the performance of differential oil in welded differentials.

- High Viscosity Oil: High viscosity oils provide a thicker lubricant that can resist shear forces better, offering enhanced protection under extreme conditions.

- Low Viscosity Oil: Low viscosity oils flow more easily, which can improve lubrication at lower temperatures but may compromise protection under high-stress situations.

- Temperature Stability: The ability of the oil to maintain its viscosity across a range of temperatures is vital for consistent performance, especially in extreme driving conditions.

- Additives: The presence of additives in diff oils can influence viscosity, helping to improve friction characteristics and protection against wear.

- Performance Under Load: The viscosity of the oil affects how it behaves under load, with higher viscosity oils generally being more effective at maintaining film strength in heavy-duty applications.

High viscosity oils are beneficial for welded differentials as they provide a robust barrier against wear and tear, especially during high torque situations commonly found in performance driving or off-road scenarios. However, they can also lead to increased drag and heat generation if the viscosity is too high for the application.

On the other hand, low viscosity oils can enhance fuel efficiency and reduce drag, but they may not offer the same level of protection in extreme conditions, making it essential to strike a balance based on the specific demands of the vehicle and driving style.

Temperature stability is a critical factor because differential oils need to perform well under varying temperatures; oils that lose viscosity when heated can lead to inadequate lubrication and increased wear. Thus, selecting a diff oil that maintains its viscosity is essential for consistent performance.

Additives in differential oils can enhance their performance by improving their viscosity index, which helps the oil maintain its viscosity across temperature changes. These additives may also provide additional benefits, such as improved oxidation stability and reduced foam, which are important for the longevity of the differential.

Finally, the performance under load is a significant consideration; oils with the right viscosity can handle the stresses placed on welded differentials, ensuring that there is sufficient lubrication to prevent metal-to-metal contact. The right viscosity will help to create a protective film that can withstand the high forces and temperatures encountered in aggressive driving conditions.

What Are the Top Recommended Brands for Diff Oil in Welded Diffs?

The top recommended brands for diff oil in welded diffs include:

- Royal Purple: Known for its high-performance synthetic oils, Royal Purple offers diff oils that provide excellent thermal stability and protection under extreme conditions. Their formulations help reduce friction and wear, which is essential for maintaining the performance of welded diffs during heavy use.

- Red Line: Red Line is a popular choice among motorsport enthusiasts, as their diff oils are specially designed to withstand high pressures and temperatures. Their oils contain a unique blend of additives that enhance lubrication and prevent foaming, ensuring consistent performance in welded differentials.

- Lucas Oil: Lucas Oil products are renowned for their superior quality and reliability. Their diff oils contain advanced additives that improve viscosity and reduce friction, making them suitable for welded diffs used in racing or off-road applications where durability is crucial.

- Mobil 1: Mobil 1 is a well-respected brand in the automotive lubrication industry, and their synthetic diff oils are formulated to provide excellent protection and performance. These oils are engineered to minimize wear and provide smooth operation, making them a solid choice for welded diffs in demanding conditions.

- Amsoil: Amsoil offers a range of synthetic diff oils that are engineered for high performance and extreme conditions. Their products are formulated with advanced chemistry to provide optimal lubrication and thermal protection, which is essential for the longevity of welded differentials.

How Do These Brands Compare in Terms of Performance and Price?

| Brand | Performance | Price | Viscosity Rating | Recommended Applications |

|---|---|---|---|---|

| Brand A | High viscosity, excellent for off-road use, enhances traction. | $40 – Mid-range price for quality performance. | 75W-90 | Off-road vehicles, trucks |

| Brand B | Good thermal stability, suitable for heavy-duty applications. | $60 – Higher price reflecting premium formulation. | 80W-140 | Heavy-duty trucks, SUVs |

| Brand C | Designed for extreme conditions, offers superior lubrication. | $30 – Budget-friendly option with reliable performance. | 75W-90 | Standard vehicles, light trucks |

| Brand D | Exceptional shear stability, improves gear life. | $50 – Competitive pricing for high performance. | 75W-110 | Racing applications, high-performance vehicles |

| Brand E | Multi-purpose lubricant with anti-wear properties. | $35 – Affordable and effective for general use. | 70W-90 | Daily drivers, light off-road use |

What Factors Should You Consider When Choosing Diff Oil for a Welded Diff?

When choosing the best diff oil for a welded diff, several factors should be considered to ensure optimal performance and durability.

- Viscosity: The viscosity of the oil affects how well it can lubricate the differential components under various temperatures and driving conditions.

- Additive package: The presence and type of additives in the oil can enhance performance, improve wear protection, and reduce friction in a welded diff.

- Compatibility: It’s essential to ensure that the oil is compatible with the materials and seals used in your differential to prevent leaks and damage.

- Operating conditions: Consider the type of driving you will be doing, as different conditions like off-roading or racing may require specific oil formulations.

- Manufacturer recommendations: Always check the vehicle or differential manufacturer’s recommendations for oil types and specifications to ensure you’re using an appropriate product.

Viscosity is a critical factor since it determines how well the oil flows and adheres to the gears inside the differential. A higher viscosity oil can provide better lubrication but may also lead to increased drag, while a lower viscosity oil might not provide adequate protection under high pressure.

The additive package is equally important as it can include friction modifiers, anti-wear agents, and detergents, all of which can enhance the performance and lifespan of a welded diff. Selecting an oil with the right additives can help in reducing noise and improving the smoothness of operation.

Compatibility with the materials in your differential is necessary to avoid issues like seal deterioration or oil breakdown, which could lead to costly repairs. Using an oil that works well with the specific materials in your diff will ensure optimal performance.

When considering operating conditions, different driving scenarios such as extreme off-roading or competitive racing can significantly influence the type of diff oil needed. Oils designed for high-stress environments usually have enhanced properties to withstand the additional heat and pressure.

Lastly, adhering to manufacturer recommendations is crucial to ensure that you’re using the right specifications for your particular setup. This can help maintain warranty coverage and ensure that the differential operates effectively without premature wear.

What Role Does Temperature Play in Oil Selection?

Temperature significantly influences the selection of differential oil for welded differentials.

- Viscosity: The viscosity of oil determines its resistance to flow, which is crucial in maintaining lubrication under varying temperatures.

- Thermal Stability: The ability of oil to withstand high temperatures without breaking down is essential for performance and longevity.

- Additives: The effectiveness of additives can vary with temperature, impacting the oil’s performance in extreme conditions.

- Operating Environment: The specific temperature range of the environment where the vehicle operates can dictate the type of oil needed for optimal performance.

Viscosity: The viscosity of differential oil is vital as it must be thick enough to provide a protective film between gears yet thin enough to flow easily at operating temperatures. In colder conditions, lower viscosity oils can improve performance by reducing drag, while in hotter climates, higher viscosity oils can prevent thinning and maintain proper lubrication under stress.

Thermal Stability: Thermal stability refers to an oil’s ability to resist oxidative breakdown when exposed to high temperatures. Oils that lack thermal stability can form sludge and deposits, leading to increased wear and tear on the differential components, which is particularly important for welded differentials that experience significant stress during operation.

Additives: Differential oils often contain various additives that enhance performance, such as anti-wear agents and friction modifiers. However, these additives can become less effective at extreme temperatures, which is why selecting an oil formulated for a specific temperature range can ensure consistent performance and protection.

Operating Environment: The temperature conditions in which a vehicle operates can greatly influence the selection of differential oil. For instance, vehicles frequently used in high-temperature environments, like racing or off-roading, may require oils formulated specifically to handle heat, whereas those used in cooler climates might benefit from oils designed to maintain fluidity in lower temperatures.

How Often Should You Change the Diff Oil in a Welded Diff for Optimal Performance?

To ensure optimal performance of a welded differential, it is essential to consider how often to change the diff oil and the type of oil used.

- Frequency of Change: It is generally recommended to change the diff oil every 10,000 to 20,000 miles, or at least once a year, depending on driving conditions and usage.

- Best Diff Oil: The best diff oil for a welded diff typically includes high-performance synthetic oils that can withstand extreme pressure and temperature.

- Condition Monitoring: Regularly checking the oil condition can help determine if it needs to be changed sooner, especially if you notice discoloration or metal shavings.

The frequency of change is critical; regular intervals help maintain lubrication, prevent wear, and ensure the welded diff operates efficiently. For those who drive in harsh conditions or engage in motorsport activities, more frequent changes may be necessary to avoid issues.

The best diff oil for a welded diff is often a synthetic gear oil with a high viscosity rating, which provides better protection under load and reduces friction. Look for oils that specifically mention compatibility with limited-slip and welded differentials, as they help enhance performance while minimizing the risk of overheating.

Monitoring the condition of the diff oil is essential as it provides insights into the health of the differential. If the oil appears burnt, cloudy, or contains debris, it may indicate that a change is overdue, which can prevent potential damage and ensure consistent performance.

What Common Issues Can Arise from Using Incompatible Diff Oil in a Welded Diff?

Using incompatible differential oil in a welded diff can lead to several common issues that may affect the performance and longevity of the differential.

- Increased Wear and Tear: Using oil that does not match the specifications for a welded diff can result in inadequate lubrication, leading to increased friction and wear on the gears and bearings. This can accelerate the deterioration of critical components, ultimately shortening the lifespan of the differential.

- Overheating: Incompatible oils may not have the appropriate thermal properties needed for high-stress environments typical of welded diffs. This can cause the oil to break down at elevated temperatures, resulting in overheating and potential failure of the differential system.

- Noise and Vibration: The wrong diff oil can lead to inconsistent lubrication, which may cause increased noise and vibration while driving. This not only affects driving comfort but also indicates that the differential is not operating as efficiently as it should.

- Foaming and Air Entrapment: Some oils may create foam under stress, which can lead to air being trapped in the oil. This foaming can reduce the oil’s ability to lubricate effectively, causing further damage and inefficiency in the differential’s operation.

- Seal and Gasket Deterioration: Incompatible oils can have chemical compositions that may adversely affect the seals and gaskets in the differential. This can lead to leaks, which compromise the integrity of the differential and require costly repairs.

- Compromised Performance: A welded diff is designed for specific performance characteristics, and using the wrong oil can hinder its ability to deliver power effectively to the wheels. This can result in reduced traction and handling, especially in demanding driving conditions.