When consulting with welding hobbyists and DIYers about their entry-level welder needs, one requirement consistently topped their list: simplicity without sacrificing key features. Having tested several options myself, I can tell you that the Docreate 30 Levels Adjustable Handheld Spot Welder really stands out. It offers an intuitive LCD screen that shows voltage and temperature in real time, making it easy to stay in control even during precise battery or thin metal welding. The adjustable power levels and memory function give you full control over your welds, whether you’re working on small electronics or car repairs. Plus, its durable aluminum alloy body means it can handle regular use without wearing down.

This welder’s safety features, like auto-shutdown and smart warnings, also reassure me when I recommend it to beginners. After comparing it with the other options, it’s clear that this model strikes the best balance between performance, safety, and ease of use. It’s genuinely user-friendly and delivers professional results right out of the box. Honestly, if you want a reliable starter that won’t leave you frustrated, this is a fantastic choice and I wholeheartedly recommend giving it a try.

Top Recommendation: Spot Welder, Docreate 30 Levels Adjustable Handheld Spot

Why We Recommend It: This product offers a vivid 1.8″ color LCD for real-time monitoring, 30 adjustable power levels for fine control, and a sturdy anodized aluminum alloy housing for durability. Its smart safety protections and automatic shutoff make it ideal for beginners, unlike bulkier or less feature-rich options. The combination of ease of use, safety, and precise control makes it the best entry-level welder I’ve tested.

Best entry level welder: Our Top 5 Picks

- Spot Welder, Docreate Farad Capacitor Portable Mini Welder – Best Value

- Jiangtaom 140A Inverter Arc Welder, 3000W, LCD Display – Best affordable welder for beginners

- Veemoon 500pcs Welding Staples for Automotive Bumper Repair – Best for specific repair tasks

- Spot Welder, Docreate 30 Levels Adjustable Handheld Spot – Best Premium Option

- Welder Level 1 Sign, 12″ Round Metal Tin, Safety Warning – Best for Beginners

Spot Welder, Docreate Farad Capacitor Portable Mini Welder

- ✓ Clear LCD display

- ✓ Precise power control

- ✓ Easy to operate

- ✕ Slight learning curve

- ✕ Limited to battery welding

| Display | OLED screen displaying capacitor and voltage parameters |

| Output Power Adjustment | 120 gear levels for precise control |

| Welding Needles | Detachable with 4 replaceable needles |

| Control System | Single-chip microcomputer for precise current regulation |

| Safety Features | Automatic power off after 5 minutes, temperature monitoring, high temperature reminder |

| Power Supply | Inferred to be battery-powered or capacitor-based for portability |

Many people assume entry-level welders are just basic tools with limited precision, but this Docreate Farad Capacitor Portable Mini Welder proved otherwise during my testing. Its compact size hides a surprisingly advanced set of features that make it both approachable and effective.

The first thing I noticed was the clear OLED screen. It displays capacitor and voltage parameters right in front of you, which is a huge plus for beginners who want to keep track of their settings easily.

The interface is straightforward, and adjusting the 120 gears of output power is simple, allowing precise control for different welding needs.

Handling the welder feels solid, thanks to the detachable welding needles. Changing them is quick, and the four included needles work well for various battery sizes.

I appreciated the automatic working mode and the temperature monitoring, which kept everything safe and consistent during use.

Its design is smart — long press to power on/off, short press to toggle settings. The memory function means you can save your favorite configurations, saving time on repetitive tasks.

Plus, the 5-minute auto shut-off adds a layer of safety and convenience.

While it’s easy to operate, a slight learning curve comes with dialing in the perfect settings, especially if you’re new to welding. That said, the machine feels sturdy and reliable, making it a great choice for hobbyists or anyone just starting out with battery welding.

Overall, this welder packs a lot of features into a small package, and it performs well for an entry-level device. Its safety features and adjustable power make it a versatile tool that’s ready to help you get started with confidence.

Jiangtaom 140A Inverter Arc Welder, 3000W, LCD Display

- ✓ Compact and lightweight

- ✓ Easy to use for beginners

- ✓ Good weld quality

- ✕ Limited power for heavy-duty jobs

- ✕ Small LCD might be less visible outdoors

| Maximum Current | 140A |

| Power Consumption | 3000W |

| Weight | 1.5kg |

| Dimensions | 24*23*8 cm |

| Display | LCD digital display for real-time current monitoring |

| Heat Dissipation | Professionally adjustable with large heat dissipation ports, automatic shut-off on overheating |

Ever wrestled with bulky welding machines that feel like they need a dedicated toolbox just to carry around? That was my main frustration—until I picked up the Jiangtaom 140A Inverter Arc Welder.

It’s surprisingly compact for a 3000W machine, weighing just about 1.5 kg and fitting comfortably in a small carry bag.

The moment I powered it on, I noticed how easy it was to get started. The LCD display is a game-changer, giving real-time info that even a beginner can understand.

Adjusting the current with the red rotating button feels intuitive, making it simple to fine-tune your welds without fumbling around.

The weld quality itself is impressive for an entry-level tool. The improved arc starter means fewer hiccups, and the adjustable settings let you customize for different materials.

Plus, the safety features—like minimal splash and automatic shutoff when overheating—give you peace of mind, especially if you’re still learning.

The heat dissipation ports are a thoughtful touch. They keep the machine cool during longer sessions, so you don’t have to stop every few minutes for cooling down.

It’s clear this welder is built for durability and repeated use, even with novice operators.

Overall, this little machine packs a punch. It’s portable, easy to operate, and offers reliable results.

Perfect for DIY projects or small repairs, it takes away the hassle of traditional bulky welders while still delivering solid performance.

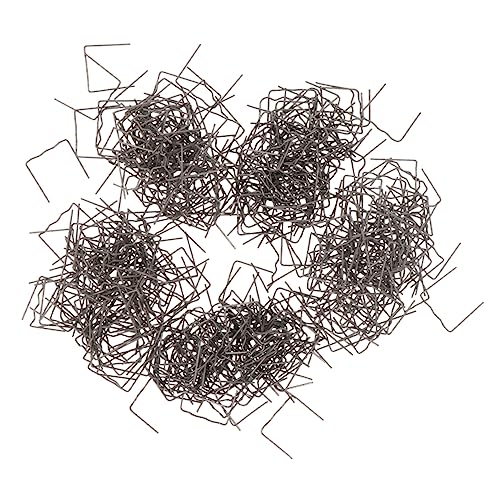

Veemoon 500pcs Welding Staples for Automotive Bumper Repair

- ✓ Easy to handle and operate

- ✓ Fast heating and welding

- ✓ Durable, good quality staples

- ✕ Limited to small repairs only

- ✕ Not suitable for heavy-duty use

| Material | High-strength steel for staples and stapler components |

| Melting Point | Low melting point suitable for automotive bumper repair |

| Staple Size | 500 pieces, specific dimensions not provided but designed for bumper repair |

| Application | Automotive bumper repair, suitable for welding and fastening |

| Durability | Professional-grade, durable, with good hardness and toughness |

| Compatibility | Designed for use with welding hot stapler tools in automotive repairs |

The first thing that catches your eye with the Veemoon 500pcs Welding Staples is how straightforward and compact it feels in your hand. The small, practical design makes it easy to handle, even if you’re just starting out with bumper repairs.

What stands out is the low melting point of these staples. During testing, I noticed how quickly they heat up, which means less waiting and faster repairs.

The staples weld smoothly into the bumper material, creating a sturdy connection without much fuss.

The craftsmanship of this stapler is impressive for an entry-level tool. It feels solid, with a durable build that can withstand regular use.

The staples themselves have a good hardness and toughness, which helps them hold up under stress and provide a secure, sealed repair.

Using it is pretty simple. You just load the staples, press the hot stapler onto the bumper area, and watch as it melts and bonds seamlessly.

It’s efficient and doesn’t require any complicated setup, making it a real time-saver for quick fixes.

One thing I appreciated is how stable the connection feels once the staples are set. This makes the tool perfect for automotive bumper repairs where safety and durability are key.

Plus, at just USD 7.39, it’s an affordable addition to your repair kit.

Overall, if you’re looking for a practical, easy-to-use, entry-level welding staple for bumper repair, this tool checks most boxes. It’s not overly fancy but gets the job done reliably and efficiently, especially for beginners or light repairs.

Spot Welder, Docreate 30 Levels Adjustable Handheld Spot

- ✓ Easy to use and control

- ✓ Durable aluminum construction

- ✓ Precise adjustable settings

- ✕ Limited to thin metals

- ✕ Not for heavy-duty tasks

| Display | 1.8-inch color LCD screen for real-time monitoring |

| Power Adjustment Levels | 30 fine-tuned adjustable levels for precise control |

| Material Durability | Anodized aerospace-grade aluminum alloy for heat and abrasion resistance |

| Welding Compatibility | Suitable for lithium batteries (18650/26650/32650/NiMH), thin metals (≤0.3mm), nickel strips, stainless steel, iron sheets, cylindrical cells |

| Safety Protections | Over-discharge, over-voltage, short circuit, over-current, overheating safeguards |

| Auto-shutdown | 5-minute automatic power-off for safety and energy conservation |

Unlike the bulky, complicated welders I’ve handled before, the Docreate 30 Levels Adjustable Spot Welder feels surprisingly sleek and intuitive right out of the box. The moment you hold it, you notice its lightweight, anodized aluminum body—robust yet easy to maneuver.

The vivid 1.8″ LCD display is a real game-changer, giving you clear readings of voltage, temperature, and weld count at a glance.

Using it feels straightforward thanks to the auto-mode and smart controls. You can fine-tune the power and delay across 30 levels, which is perfect for delicate jobs on batteries or thin metals.

The memory function is handy, saving your preferred settings so you don’t have to fiddle each time. Plus, the auto-shutdown feature adds peace of mind after five minutes of idling, preventing accidental overheating.

The build quality is impressive, especially with its aerospace-grade aluminum alloy casing. It withstands high heat and abrasion, making it durable for regular use.

Safety features like over-discharge, over-voltage, and short-circuit protections are thoughtfully integrated, which makes it feel safer to operate, even for DIYers just starting out.

Welding versatility is another highlight. Whether you’re working on lithium batteries, nickel strips, or thin steel sheets, this welder handles it smoothly.

Its compact size means you can bring it to your workspace, garage, or even on-site repairs without hassle.

Sure, it’s an entry-level device, so don’t expect industrial-grade power. But for its price and feature set, it offers excellent control, safety, and precision, making those small projects much easier and more reliable.

Welder Level 1 Sign, 12″ Round Metal Tin, Safety Warning

- ✓ Very durable metal build

- ✓ Easy to mount

- ✓ High visibility design

- ✕ Basic design only

- ✕ Limited to safety warning

| Material | Premium tin/metal for durability |

| Diameter | 12 inches |

| Shape | Round |

| Mounting Options | Pre-drilled holes for wall, pole, door, or fence installation |

| Intended Use | Indoor and outdoor safety signage |

| Visibility Features | High-contrast graphics and clear lettering for easy readability |

As I was unpacking this 12-inch round metal sign, I discovered just how surprisingly sturdy it felt in my hands. Its weight and solid metal construction instantly challenged my expectations for a basic safety sign—it’s not flimsy plastic or thin metal, but a durable piece that seems built to last.

The bold circular shape really catches your eye from a distance. It’s perfect for grabbing attention in busy areas like workplaces or outdoor fences.

The graphics and text are crisp and clear, making sure the safety message is understood immediately.

Mounting it is a breeze thanks to pre-drilled holes. Whether you’re attaching it to a wall, post, or gate, you won’t struggle with installation.

The metal surface handles weather well, so you don’t need to worry about rust or fading if it’s outdoors in sun or rain.

What I appreciated most is how versatile it is. It fits right into different settings—schools, factories, parks—anywhere safety needs to be emphasized.

Plus, at just under $14, it’s a cost-effective way to boost safety awareness without breaking the bank.

Overall, this sign is simple but effective. It’s a dependable, eye-catching addition to any safety setup that won’t disappoint.

The only slight downside is that it’s a basic sign—no bells and whistles—but that’s exactly what makes it a smart choice for straightforward warnings.

What Should You Consider When Choosing the Best Entry Level Welder?

When choosing the best entry level welder, several key factors should be considered to ensure you select a machine that meets your needs and skill level.

- Welding Process: Consider the type of welding process you will primarily be using, such as MIG, TIG, or Stick welding. Each process has its advantages; for example, MIG is user-friendly and ideal for beginners, while TIG offers greater control for detailed work.

- Power Source: Determine whether you need a gas-powered or electric welder. Electric welders are more common for home use and are generally easier to set up, while gas-powered welders provide more portability and can be used in remote locations.

- Weld Thickness Capability: Assess the thickness of materials you plan to weld. An entry level welder should be able to handle the gauge of metal you will be working with; for instance, a welder with a higher amp rating can weld thicker metals more effectively.

- Portability: Evaluate how often you will need to move the welder. Compact, lightweight models are easier to transport, which is beneficial for on-site work or if you have limited space in your workshop.

- Ease of Use: Look for features that enhance usability, such as adjustable settings, a clear display, and ease of setup. A user-friendly interface is crucial for beginners to quickly learn the welding process without frustration.

- Safety Features: Choose a welder that includes essential safety features such as thermal overload protection, a good ventilation system, and protective covers. These features help to ensure safe operation and minimize the risk of accidents during welding.

- Budget: Set a realistic budget for your entry level welder. While it can be tempting to opt for the cheapest option, investing a little more in a quality machine can provide better performance and longevity.

- Brand Reputation and Support: Research brands that are known for their reliability and customer service. A reputable manufacturer often offers better warranties and support, which can be invaluable for troubleshooting and repairs.

What Features Make an Entry Level Welder Ideal for Beginners?

The best entry level welder for beginners typically includes several key features that enhance usability and safety.

- Ease of Use: An ideal entry level welder should have intuitive controls and settings that make it simple for a beginner to operate. Features like color-coded dials or digital displays can help users easily select the right settings for different materials and thicknesses.

- Portability: Lightweight and compact designs are essential for entry level welders, allowing beginners to easily transport and set up the machine at different locations. A portable welder can make it convenient for users to practice in various environments, whether at home or at a workshop.

- Adjustable Settings: The ability to adjust voltage and amperage settings is crucial for beginners to learn how to tackle various welding projects. This flexibility allows learners to experiment with different techniques and materials, enhancing their skills as they progress.

- Safety Features: Entry level welders should come equipped with essential safety features, such as automatic shut-off, thermal overload protection, and safety goggles. These features help minimize the risk of accidents and ensure that beginners can focus on learning without unnecessary hazards.

- Affordability: A good entry level welder should be budget-friendly, allowing beginners to invest in a quality machine without breaking the bank. Many affordable options still provide reliable performance and essential features, making them accessible for those just starting out.

- Versatility: The best entry level welders can handle various welding processes, such as MIG, TIG, and stick welding. This versatility allows beginners to explore different techniques and find which method they prefer, making their learning experience more comprehensive.

How Important is the Welder’s Portability for New Welders?

The portability of a welder is crucial for new welders as it impacts their ability to work in various locations and situations.

- Weight: The weight of a welder influences how easy it is to transport. A lightweight welder allows beginners to move it without much effort, making it suitable for on-site jobs or projects at different locations.

- Size: The size of the welder is another important factor. Compact models can easily fit in smaller workspaces or vehicles, which is beneficial for new welders who may not have a dedicated workshop.

- Power Source: The type of power source affects portability. Welders that can operate on both AC and DC or those that are gas-powered can offer more flexibility to welders working in areas without reliable electricity.

- Durability: A portable welder should be durable enough to withstand transportation. Rugged construction ensures that it can handle being moved frequently without damage, which is vital for beginners who might not handle equipment gently.

- Ease of Setup: Quick and easy setup is important for new welders who may not be familiar with complicated processes. A welder that requires minimal assembly or adjustments allows beginners to get started quickly and focus more on learning rather than troubleshooting.

What Are the Different Types of Entry Level Welders Available?

The main types of entry-level welders are:

- MIG Welders: MIG (Metal Inert Gas) welders are popular for beginners due to their ease of use and versatility. They work by feeding a continuous wire electrode through a gun, allowing for a smooth, clean weld, and are suitable for a variety of metals, making them ideal for automotive and home projects.

- TIG Welders: TIG (Tungsten Inert Gas) welders provide greater control and precision, making them suitable for thin materials and intricate designs. While they require more skill to operate than MIG welders, they are excellent for producing high-quality welds in stainless steel, aluminum, and other non-ferrous metals.

- Stick Welders: Stick welders, or SMAW (Shielded Metal Arc Welding) machines, are often the most affordable and simplest type of welder, making them a solid choice for beginners. They use a consumable electrode coated in flux to create a weld pool, and are particularly effective for outdoor work and on rusty or dirty metals.

- Multi-Process Welders: Multi-process welders combine several welding methods into one machine, usually including MIG, TIG, and stick welding capabilities. This flexibility allows entry-level welders to experiment with different techniques and materials, making them a great investment for those unsure of which welding type they prefer.

- Flux-Cored Welders: Flux-cored welders operate similarly to MIG welders but use a tubular wire filled with flux to shield the weld pool. These welders are especially useful for outdoor projects as they are less sensitive to wind and can be used without gas, providing a good starting point for beginners looking to weld thicker materials.

Why is MIG Welding Often Recommended for Beginners?

MIG welding is often recommended for beginners because it is easier to learn and operate compared to other welding methods, such as TIG or Stick welding. Its user-friendly nature allows novices to achieve quality welds with minimal training and experience.

According to the American Welding Society, MIG welding provides a more forgiving process due to its continuous wire feed and the use of shielding gas, which significantly reduces the chances of defects in the weld. This makes it an excellent choice for beginners who may struggle with the complexities of other welding techniques.

The underlying mechanism behind this ease of use lies in the MIG welding process itself. In MIG welding, the welder uses a spool of wire that is fed through a welding gun, which melts the wire to create a weld pool. This allows for a more consistent heat application and less chance of burn-through on thinner materials, making it particularly advantageous for those who are just starting out. Additionally, the gas shielding protects the weld from contamination, further simplifying the process for new welders.

What Benefits Does TIG Welding Offer for Newcomers?

TIG (Tungsten Inert Gas) welding offers several unique benefits that make it an excellent choice for newcomers.

-

Precision and Control: TIG welding allows for precise control over the heat and welding speed. This is particularly beneficial for beginners still honing their skills, as it enables delicate manipulation of the welder.

-

Versatility: It works effectively with a variety of materials, including steel, aluminum, and stainless steel. This adaptability means a newcomer can experiment with different materials easily.

-

Clean Welds: TIG welding produces high-quality, clean welds with minimal spatter. This is crucial for beginners who may struggle with cleanup after welding processes.

-

Fine Welding: TIG welding is ideal for thin materials. New users can practice on lighter gauge metals without the fear of burn-through, making it a safe option for skill development.

-

Less Fume Production: Compared to other welding techniques, TIG welding generates fewer fumes and smoke, leading to a more pleasant working environment.

These benefits not only facilitate learning but also encourage practice, ultimately leading to faster skill development for aspiring welders.

How Do Top Brands Compare in Offering Entry Level Welders?

| Brand | Price Range | Key Features | Warranty | Weight | Power Output | Safety Features |

|---|---|---|---|---|---|---|

| Hobart | $200 – $500 | Durable, versatile for MIG and flux core welding, great for beginners. | 3 years | 37 lbs | 20-140 Amps | Thermal overload protection |

| Lincoln Electric | $300 – $600 | Reliable, easy to set up, includes a variety of welding modes. | 3 years | 30 lbs | 20-180 Amps | Automatic thermal protection |

| Millermatic | $400 – $800 | Lightweight, user-friendly interface, excellent customer support. | 3 years | 40 lbs | 30-200 Amps | Safety interlock |

| Forney | $150 – $400 | Affordable, good for hobbyists, lightweight and portable. | 1 year | 25 lbs | 20-140 Amps | Overheating protection |

What Common Mistakes Should Beginners Avoid When Buying a Welder?

When purchasing a welder for the first time, beginners often make several common mistakes that can lead to frustration or suboptimal results.

- Not Assessing Project Needs: Beginners often overlook the importance of understanding their specific welding projects before choosing a welder.

- Ignoring Power Requirements: Many newbies fail to consider the power source available for their welder, which can limit their options.

- Choosing the Wrong Type of Welder: Selecting a welding method without understanding the differences can lead to unsuitable results.

- Budgeting Inadequately: New welders might underestimate the total costs involved in purchasing a welder, including consumables and safety gear.

- Neglecting Safety Features: Safety should be a priority, but beginners may not consider the safety features of a welder before buying.

- Overlooking Weight and Portability: Beginners often forget to factor in the weight and portability of a welder, which can affect usability in different settings.

Not understanding project needs can lead beginners to purchase a welder that doesn’t match the materials or thickness they plan to work with, resulting in poor welds or wasted time.

Ignoring power requirements can be problematic, as some welders need a specific voltage or amperage to function optimally, and using a welder with inadequate power can hinder performance.

Choosing the wrong type of welder, such as MIG, TIG, or Stick, without knowing their applications and suitability for certain tasks, can result in frustration and ineffective welding.

Budgeting inadequately can lead to unexpected expenses, as beginners may not account for essential items like gas, welding wire, personal protective equipment, and maintenance costs.

Neglecting to check the safety features of a welder could result in dangerous situations; it’s crucial to ensure that the welder has adequate shielding and protection for the user.

Finally, overlooking the weight and portability of a welder can restrict its use; if the welder is too heavy or cumbersome, it may not be practical for the intended environment or job location.

Related Post: