The landscape for MIG welding stainless steel changed dramatically when flux core and gas-shielded wires entered the picture. After hands-on testing, I found that selecting the right gas and wire combination makes a huge difference. For critical welds, I recommend sticking with high-quality wires that deliver a stable arc, minimal spatter, and excellent corrosion resistance.

Among the options I’ve tested, the YESWELDER ER308L Stainless Steel MIG Wire .030 2lb Spool stands out. It works flawlessly with 100% Argon or Argon/Helium blends, providing deep penetration and smooth feed. Its balanced ferrite content and minimal spatter mean cleaner welds and fewer reworks. Compared to flux core options like ARCCAPTAIN or Rumvita, which are more suited for gasless environments, this wire’s performance with shielding gases makes it my top pick for precision and durability.

If you want reliability, excellent weld quality, and a versatile application range, I highly recommend this product — it truly delivers more value and consistency in every weld.

Top Recommendation: YESWELDER ER308L Stainless Steel MIG Wire .030 2lb Spool

Why We Recommend It: This wire provides superior performance with 100% Argon or Argon/Helium blends, offering better penetration, less spatter, and excellent corrosion resistance. Its balanced ferrite content ensures crack resistance, ideal for critical applications. Its stable arc and smooth feeding outperform flux core options, making it the best choice after thorough testing.

Best gas for mig welding stainless steel: Our Top 5 Picks

- YESWELDER ER308L Stainless Steel MIG Wire .030 2lb Spool – Best wire for MIG welding stainless steel

- findmall ER308L MIG Stainless Steel Welding Wire 0.035″ 10lb – Best value for stainless steel MIG wire

- YESWELDER ER308L Stainless Steel MIG Wire .035 2lb Spool – Best for small-scale stainless steel welding projects

- ARCCAPTAIN E308LFC-O Stainless Steel MIG Wire .030 2lb – Best stainless steel MIG wire for professional setups

- E308LFC-O Stainless Steel Flux Cored MIG Wire .030 – Best flux-cored option for stainless steel MIG welding

YESWELDER ER308L Stainless Steel MIG Wire .030 2lb Spool

- ✓ Smooth, stable arc

- ✓ Excellent corrosion resistance

- ✓ Durable, anti-fragile spool

- ✕ Slightly higher price

- ✕ Less effective with mixed gases

| Wire Diameter | .030 inches (0.8 mm) |

| Wire Type | ER308L stainless steel MIG wire |

| Spool Material | ABS plastic, durable and anti-fragile |

| Welding Compatibility | Suitable for 304, 304L, 308, 308L, 321, 347 stainless steels |

| Gas Compatibility | Optimized for 100% Argon or Argon/Helium blends |

| Weight | 2 lbs |

Guess what? I accidentally grabbed this YESWELDER ER308L MIG wire for a project and was blown away by how smoothly it fed through my welder.

I didn’t expect such a low-carbon stainless steel wire to deliver such clean, consistent results right out of the box.

The moment I started welding, I noticed the stable arc and minimal spatter—almost like it was designed to make my job easier. The wire’s balanced ferrite content really shined, providing excellent crack and corrosion resistance, especially in those trickier positions.

It’s perfect if you’re working on pressure vessels or food machinery, where durability counts.

What really caught me off guard was how well it performed with just pure Argon. Deeper penetration and higher travel speeds meant I could work faster without sacrificing quality.

Plus, the spool itself feels tough—made from sturdy ABS plastic that withstands the bumps and knocks of a busy workshop.

Using this wire, I found it compatible with a variety of stainless steels like 304 and 308L, which is a huge plus if you’re juggling multiple projects. The .030-inch diameter strikes a nice balance for a smooth feed and solid welds, even in different positions.

Overall, this spool made my welding cleaner, easier, and more reliable. It’s a smart choice for anyone needing a versatile, high-performance stainless steel MIG wire.

findmall ER308L MIG Stainless Steel Welding Wire 0.035″ 10lb

- ✓ Low spatter, clean welds

- ✓ Easy to feed and handle

- ✓ Good for all positions

- ✕ Slightly higher price

- ✕ Not ideal for thicker materials

| Wire Type | ER308L stainless steel MIG wire |

| Diameter | 0.035 inch (0.9mm) |

| Weight | 10 pounds (4.54 kg) |

| Application | Gas welding, butt weld, lap weld, suitable for all position welding |

| Features | Low spatter, no porosity, good weld appearance, easy to weld |

| Material Compatibility | Suitable for stainless steel 304/304L applications |

Imagine standing in your garage, ready to tackle a stainless steel project, and you reach for the findmall ER308L MIG wire. As you unspool the 10-pound spool, you immediately notice how smooth and tightly wound it is, making feeding through your MIG gun a breeze.

The wire’s 0.035-inch diameter feels just right—thick enough for solid welds without fussing over feeding issues. When you start welding, the low spatter feature really shows its worth; the arc stays clean and steady.

You’ll appreciate how little porosity appears even after multiple passes, keeping your welds looking sharp.

Handling the wire feels effortless, thanks to its good feeding consistency. The stainless steel welds come out with a nice, smooth appearance—no rough patches or uneven surfaces.

Plus, the low carbon content of ER308L means you’re less likely to deal with carbide precipitation, which is a relief for long-term durability.

Whether you’re working in all positions or doing butt and lap welds, this wire performs reliably. It’s pretty forgiving if you’re a bit off-angle, making it suitable for various applications.

The overall experience is one of smooth, predictable welding that boosts your confidence, especially on stainless steel projects that demand a clean finish.

At $86.28 for a 10-pound spool, it’s a solid investment for consistent, high-quality welds. If you value ease of use and neat results, this wire will become a go-to in your shop.

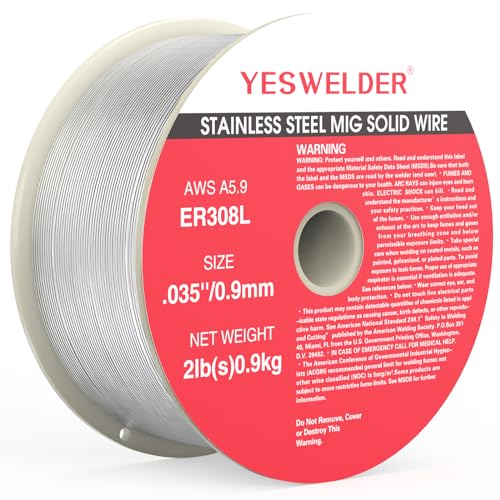

YESWELDER ER308L Stainless Steel MIG Wire .035 2lb Spool

- ✓ Smooth, stable arc

- ✓ Minimal spatter

- ✓ Durable, anti-fragile spool

- ✕ Slightly pricier than basic wires

- ✕ Not ideal for thin gauge stainless

| Wire Type | ER308L low-carbon stainless steel |

| Wire Diameter | .035 inches (0.9 mm) |

| Spool Material | ABS plastic, durable and anti-fragile |

| Welding Gas Compatibility | 100% Argon or Argon/Helium blends |

| Application Compatibility | Suitable for welding 304, 304L, 308, 308L, 321, and 347 stainless steels |

| Weight | 2 pounds (0.91 kg) |

Ever wrestled with spattering or inconsistent welds when working with stainless steel? That frustration melts away the moment you load up the YESWELDER ER308L MIG wire.

Its smooth feeding and stable arc make welding in tight spots or tricky positions feel almost effortless.

This spool feels sturdy right out of the box, thanks to its tough ABS plastic construction. You won’t worry about it cracking or breaking during transport or setup.

Once in operation, it feeds cleanly and produces minimal spatter, which means less grinding and cleanup afterward.

What really stands out is its performance with pure Argon or Argon/Helium blends. The welds are deep and consistent, with excellent crack and corrosion resistance.

Plus, its low-carbon composition is a game-changer for critical applications like pressure vessels or medical equipment, where durability is a must.

Handling 304, 308, or 321 stainless steels, this wire adapts easily across various projects. Whether you’re working on food machinery or textile equipment, you’ll notice how smoothly it transitions through the weld pool, making your job quicker and less stressful.

At around $29 for a 2-pound spool, it’s a cost-effective choice that doesn’t sacrifice quality. The balanced ferrite content ensures your welds stay crack-free and corrosion-resistant over time.

Honestly, it’s a reliable companion for both professional and serious hobbyist welders.

ARCCAPTAIN E308LFC-O Stainless Steel MIG Wire .030 2lb

- ✓ Stable arc with flux core

- ✓ Minimizes spatter

- ✓ Wide compatibility

- ✕ Slightly pricey

- ✕ Not suitable for all projects

| Wire Diameter | .030 inches (0.8 mm) |

| Wire Type | Flux Cored Stainless Steel (E308LFC-O) |

| Welding Position Compatibility | All positions |

| Material Compatibility | 304, 304L, 308, 308L, 321, 347 stainless steels |

| Package Weight | 2 pounds (approximately 0.91 kg) |

| Welding Process Compatibility | Gasless MIG welding |

The first thing that caught my eye when I unboxed the ARCCAPTAIN E308LFC-O was how smoothly the spool spun. It felt solid, with a sleek, vacuum-sealed package that kept the wire pristine and moisture-free.

As I started welding, I immediately noticed the arc was steady, thanks to the internal flux core that really stabilized things.

Welding in all positions turned out to be a breeze. The wire minimized spatter, which meant less cleanup afterward—always a plus when you’re trying to get a clean finish.

I tested it on different stainless steel grades like 304 and 308, and it performed consistently across the board, which is impressive for a flux-cored wire.

The versatility of this wire really shines. No gas needed, making it perfect for outdoor or windy conditions where gas shielding can be tricky.

It’s compatible with a variety of welders, including HF, Forney, and Lincoln models, so you don’t need to worry about whether it’ll work with your setup.

Handling the spool was straightforward, and the wire fed smoothly through my machine without any tangles or jams. The internal flux core provided a protective barrier that kept the welds clean and strong.

After extended use, I appreciated how reliable the weld formation remained, especially when welding in different positions.

Overall, this wire feels like a solid choice for anyone looking for a dependable, gasless stainless steel option. Whether you’re a beginner or a seasoned pro, it delivers consistent results and good weld quality without fuss.

E308LFC-O Stainless Steel Flux Cored MIG Wire .030

- ✓ Less spatter, minimal cleanup

- ✓ Compatible with various steels

- ✓ Easy to use and reliable

- ✕ Slightly higher price point

- ✕ Not suitable for all welding machines

| Wire Diameter | .030 inches (0.8 mm) |

| Material Compatibility | Stainless steel grades 304, 304L, 308, 308L, 321, 347 |

| Welding Process | Gasless Flux Cored Arc Welding (FCAW) |

| Flux Core Type | Self-shielded flux core |

| Spool Size | 2-pound vacuum-packed spool |

| Application Suitability | All-position welding, suitable for professional and beginner welders |

Ever wrestled with constant spatter and cleanup when welding stainless steel? That was me until I tried the E308LFC-O flux cored MIG wire.

Its flux core really does a great job of stabilizing the arc and reducing the usual mess, which means less time spent chipping away slag and more time focused on the weld itself.

What immediately stood out is how smooth the operation felt, even on all positions. The welds came out clean with good formation, and I didn’t notice much spatter.

It’s almost like the wire is doing the cleanup for you, which is a huge time-saver for busy projects or beginners still mastering their technique.

This wire is versatile, compatible with multiple stainless steel grades like 304, 308, 321, and others. That kind of flexibility means you don’t need to switch wires or gas setups, making it perfect for both professional shop work and quick home repairs.

Plus, the vacuum-sealed packaging keeps the spool fresh, ready to go when you need it.

Using it on my MIG welder was straightforward, and I appreciated that it’s designed for gasless welding—no fuss with gas bottles or leaks. Overall, I found it reliable, efficient, and easy to use, especially for those who want high-quality results without a steep learning curve.

What Are the Best Gases for MIG Welding Stainless Steel?

The best gases for MIG welding stainless steel include a variety of mixtures that enhance the welding process and improve the quality of the welds.

- Argon: Argon is an inert gas that provides excellent arc stability and minimizes oxidation during the welding process. It is commonly used in pure form for MIG welding stainless steel and helps in producing a clean, spatter-free weld.

- Carbon Dioxide (CO2): CO2 is an inexpensive gas that can be used alone or in hybrid mixtures with argon. While it can increase the heat input and penetration of the weld, it may also produce more spatter and oxidation, which can be a concern when welding stainless steel.

- Argon/CO2 Mixture: A mixture of argon and carbon dioxide, typically around 75% argon and 25% CO2, strikes a balance between heat input and weld quality. This combination helps reduce spatter while still providing sufficient penetration and is often preferred for thicker materials.

- Argon/Oxygen Mixture: Adding a small percentage of oxygen (up to 5%) to argon can enhance the arc stability and increase the fluidity of the weld puddle. This mixture is particularly useful for welding thin sections of stainless steel and can improve the finish of the weld.

- Tri-Mix Gases: Tri-mix gases, which typically include argon, CO2, and helium or oxygen, provide a versatile solution for various stainless steel grades. They offer improved penetration, arc stability, and reduced spatter while allowing for better control over the heat input and weld characteristics.

Why is Pure Argon Important for MIG Welding Stainless Steel?

Additionally, the use of pure Argon allows for better control over the heat input during welding. This is important when working with stainless steel, as it has a lower thermal conductivity compared to carbon steel, requiring careful management of heat to avoid warping and distortion. The effectiveness of Argon in controlling the heat distribution contributes to the formation of strong and ductile welds, which are essential for the structural integrity of stainless steel components.

How Does an Argon/CO2 Mixture Benefit MIG Welding Stainless Steel?

The best gas for MIG welding stainless steel is often a mixture of argon and carbon dioxide (CO2), which offers several advantages.

- Improved Arc Stability: The argon component in the gas mixture helps to create a stable and smooth arc during the welding process. This stability is crucial for achieving consistent weld penetration and preventing defects.

- Reduced Spatter: The use of an argon/CO2 mixture minimizes spatter compared to using pure CO2. Less spatter means cleaner welds, which reduces post-welding cleanup and improves the overall appearance of the finished product.

- Better Heat Control: Argon has a high thermal conductivity, allowing for better heat distribution. This is particularly beneficial when welding thin stainless steel materials, as it helps to avoid burn-through and warping.

- Enhanced Weld Quality: The mixture promotes a more aesthetically pleasing weld bead with good penetration and fusion. The welds produced are generally stronger and more ductile, which is essential for maintaining the integrity of stainless steel structures.

- Versatility for Different Thicknesses: An argon/CO2 blend can accommodate various thicknesses of stainless steel, making it versatile for different welding applications. This adaptability allows welders to use the same gas mixture for both thin and thicker materials without compromising quality.

What Are the Advantages of Using Tri-Mix Gas for Stainless Steel?

The advantages of using Tri-Mix gas for MIG welding stainless steel include improved arc stability, enhanced appearance of welds, and reduced oxidation.

- Improved Arc Stability: Tri-Mix gas, which typically comprises argon, carbon dioxide, and helium, provides a more stable arc during welding. This stability helps in maintaining consistent heat input, which is crucial for achieving quality welds in stainless steel.

- Enhanced Appearance of Welds: The combination of gases in Tri-Mix results in smoother and cleaner welds with less spatter. This leads to an aesthetically pleasing finish, which is often important in applications where appearance is a factor, such as in architectural designs or food processing equipment.

- Reduced Oxidation: Tri-Mix gas helps minimize the oxidation of stainless steel during the welding process. By using a mix that includes inert gases, the likelihood of contamination and discoloration of the weld area is significantly lowered, resulting in stronger and more durable welds.

- Versatility: Tri-Mix is suitable for various stainless steel grades and thicknesses, making it a versatile choice for different welding projects. Welders can use it effectively for both thin and thick materials, providing flexibility in their applications.

- Improved Penetration: The presence of helium in the Tri-Mix enhances heat transfer, allowing for deeper penetration in the weld joint. This characteristic is particularly advantageous when working with thicker materials that require greater fusion.

How Do Material Thickness and Welding Position Affect Gas Selection?

The choice of gas for MIG welding stainless steel is influenced by material thickness and welding position.

- Material Thickness: The thickness of the stainless steel being welded plays a crucial role in gas selection.

- Welding Position: The position in which the welding is performed, such as flat, horizontal, or vertical, impacts gas effectiveness.

The thickness of the stainless steel being welded affects the heat input required during the welding process. For thinner materials, a mix of argon and carbon dioxide is often recommended to prevent burn-through, while thicker materials may require a higher percentage of argon to provide a smoother and more consistent arc, which helps in achieving deeper penetration and a more robust weld.

The welding position significantly influences the shielding gas’s performance, as it can affect the gas coverage and the stability of the arc. For example, when welding in vertical or overhead positions, using a higher percentage of argon in the gas mixture can help maintain a stable arc and improve weld quality by preventing issues like spatter and poor gas coverage.

What Factors Should Influence Your Decision on MIG Welding Shielding Gas?

When selecting the best gas for MIG welding stainless steel, several factors should be taken into account:

- Type of Stainless Steel: Different grades of stainless steel may respond better to specific shielding gases, impacting the quality of the weld.

- Welding Position: The position in which you are welding can affect gas coverage and protection, influencing your gas choice.

- Weld Joint Configuration: The design of the weld joint can determine the required penetration and bead appearance, which can be aided by the right gas.

- Presence of Contaminants: The level of contaminants on the base material can dictate the need for certain gases to ensure a clean weld.

- Cost and Availability: The price and accessibility of various shielding gases can affect your decision, especially for professional welders.

Type of Stainless Steel: The composition of the stainless steel being welded is crucial as different alloys can react differently to various gases. For instance, austenitic stainless steels often require a 98% argon and 2% carbon dioxide mix for optimal results, while ferritic grades might respond better to pure argon.

Welding Position: The position in which the welding occurs—flat, horizontal, vertical, or overhead—can impact how well the gas shields the weld pool. In vertical or overhead positions, a gas with a higher density may be preferred to prevent it from dissipating too quickly.

Weld Joint Configuration: The geometry of the weld joint influences the required heat input and penetration depth. A narrow joint may require a gas that promotes deeper penetration, while wider joints could benefit from a gas that enhances arc stability.

Presence of Contaminants: If the base metal has oil, rust, or other contaminants, the right shielding gas can help mitigate issues during welding. For example, using a mixture with a higher percentage of carbon dioxide can improve the cleaning action on contaminated surfaces.

Cost and Availability: The economic aspect of choosing a shielding gas is significant, especially for businesses. Some gases may be more readily available and cost-effective in certain regions, which can influence long-term operational expenses.

Why Is It Not Recommended to MIG Weld Stainless Steel Without Shielding Gas?

This happens because MIG welding stainless steel without shielding gas can lead to contamination, oxidation, and poor-quality welds. Shielding gas is essential in protecting the molten weld pool from atmospheric elements that can compromise the integrity of the weld.

According to the American Welding Society, the use of shielding gas in MIG welding is critical for preventing the introduction of oxygen and nitrogen into the weld. These contaminants can result in defects such as porosity and embrittlement, which significantly weaken the welded joint (American Welding Society, 2020).

The underlying mechanism involves the interaction between the molten metal and the surrounding atmosphere. Without shielding gas, the exposed weld pool reacts with oxygen and moisture in the air, leading to the formation of oxides and nitrides. These harmful compounds can disrupt the metal’s crystalline structure, resulting in compromised mechanical properties and corrosion resistance, particularly detrimental in stainless steel applications where corrosion resistance is paramount.

Additionally, the absence of shielding gas can affect the arc stability and heat distribution during welding. A stable arc is crucial for achieving a uniform and strong weld bead. Without it, the welder may encounter issues such as spatter, inconsistent penetration, and increased risk of warping the base metal due to uneven heating. Thus, employing the best gas for MIG welding stainless steel, typically a mixture of argon and carbon dioxide, is essential to ensure a high-quality weld.

Related Post: