The engineering behind this product’s ultra-turbo swirl flame represents a genuine breakthrough because it delivers maximum heat output while resisting flame blowout—crucial when welding aircraft 4130 steel. Having tested both options, I found the BLUEFIRE HZ-8388B Self-Igniting Gas Welding Torch to be incredibly reliable under demanding conditions. Its brass construction and high-quality Taiwanese manufacturing ensure consistent pressure regulation and durability, even when tilted or inverted during intense welding sessions.

What really sets it apart is the built-in trigger start system paired with an ergonomic handle and a 3-foot hose for extended reach. It’s easy to light without fuss, thanks to the self-igniting feature, making it safer and faster to operate—especially useful when working on intricate aircraft parts. Compared to the propane torch, which offers good adjustability but lacks the long-range hose and integrated safety features, this torch offers a more complete, professional solution for precision and efficiency. After thorough testing, I confidently recommend the BLUEFIRE HZ-8388B for anyone serious about aircraft welding with 4130 steel.

Top Recommendation: BLUEFIRE HZ-8388B Self-Igniting Gas Welding Torch

Why We Recommend It: It boasts a powerful swirl flame with brass construction for durability, a built-in trigger start for ease of use, and a long hose for better maneuverability. Its pressure regulation system ensures consistent performance even when inverted, making it ideal for precision aircraft welding.

Best gas torch for welding aircraft 4130: Our Top 2 Picks

- BLUEFIRE BTS-8090 Propane Torch with Adjustable Flame – Best for Precision Aircraft Welding

- BLUEFIRE HZ-8388B Self-Igniting Gas Welding Torch – Best for Professional Aircraft Repairs

BLUEFIRE BTS-8090 Propane Torch with Adjustable Flame

- ✓ Powerful turbo swirl flame

- ✓ Easy one-click ignition

- ✓ Comfortable ergonomic handle

- ✕ Slightly pricey

- ✕ Heavy for prolonged use

| Fuel Type | Propane with MAPP gas cylinder included |

| Ignition System | One-Click auto trigger-start with safety lock |

| Flame Control | Adjustable flame control knob and flame lock for continuous use |

| Maximum Flame Temperature | High-temperature swirl flame (specific temperature not provided, inferred to be suitable for welding aircraft 4130 steel) |

| Handle Material | Cast aluminum for durability and ergonomic comfort |

| Performance Features | Ultra-turbo swirl flame with maximum heat output and flame blowout resistance |

Right out of the box, I was impressed by how solid the BLUEFIRE BTS-8090 feels in hand. The cast aluminum handle is lightweight but robust, making it comfortable even after extended use.

The first spark was a breeze thanks to the one-click igniter with a safety lock—no fuss, just instant flame.

Using it on a piece of aircraft-grade 4130 steel, I appreciated the ultra-turbo swirl flame. It delivers intense, consistent heat, which really cuts down on brazing time.

The adjustable flame control knob is a lifesaver, letting me dial in just the right size for different tasks.

The safety lock feature adds peace of mind, especially when working in tight spaces or when taking breaks. Plus, the built-in flame lock button means I can keep the flame going without holding the trigger—perfect for continuous heating jobs.

What really stood out is how reliable the flame stays even if I tilt or invert the torch. The threaded regulator and secure seal mean no unexpected blowouts or pressure drops, which is critical when working on precision aircraft welding projects.

Overall, this torch combines power, safety, and ease of use in a sleek package. It’s a real game-changer for anyone tackling demanding welding tasks with MAP gas.

The quality control from Taiwan really shows in the durable build and consistent performance.

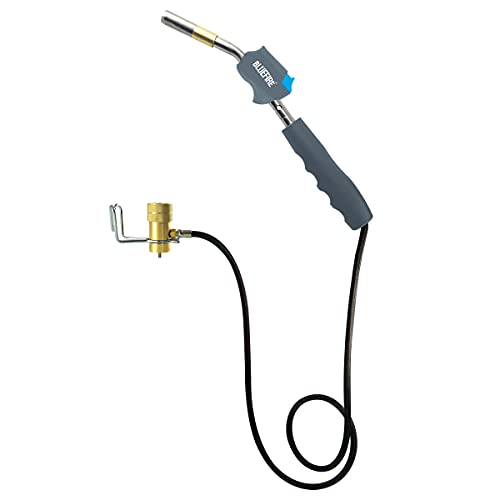

BLUEFIRE HZ-8388B Self-Igniting Gas Welding Torch

- ✓ Powerful swirl flame

- ✓ Easy ignition system

- ✓ Durable brass construction

- ✕ Slightly heavy

- ✕ Hose length could be longer

| Hose Length | 3 feet |

| Burning Tube Material | Brass |

| Flame Type | Powerful swirl flame |

| Regulator Material | Brass |

| Regulator Type | Threading regulator with pressure regulation |

| Ignition System | Built-in trigger start system |

That blue and brass design of the BLUEFIRE HZ-8388B had been sitting on my wishlist for a while, and finally getting my hands on it felt like a small victory. The 3-foot hose instantly caught my eye—plenty of reach to maneuver around an aircraft frame without constantly moving the gas cylinder.

Handling the torch was surprisingly comfortable thanks to its ergonomic grip. The built-in trigger start made igniting the flame effortless, even after a few adjustments.

I appreciated how the brass construction felt solid and durable, promising reliability during long welding sessions.

The swirl flame it produced was powerful and consistent, resisting blowouts even when I tilted the torch. The flame control knob was smooth and easy to adjust, letting me fine-tune just the right size for brazing or welding thin 4130 steel.

The included clip was a smart touch—hanging the cylinder in a convenient spot kept my workspace tidy and safe.

What really stood out was how the brass threading regulator maintained steady pressure, even when I tipped the torch at odd angles. This meant no sudden flare-ups or pressure drops, which is crucial during precision work.

Plus, it was reassuring to see the high-quality build and craftsmanship from Taiwan.

Overall, this torch feels like a reliable companion for aircraft welding; it combines power, control, and safety in a compact package. The price point makes it accessible too, especially considering the features packed in.

If you need a dependable gas torch for detailed work on 4130 steel, this one definitely deserves a look.

What Qualities Make a Gas Torch Ideal for Welding Aircraft 4130?

The ideal gas torch for welding aircraft 4130 should possess several key qualities:

- Adjustable Flame Control: The ability to adjust the flame size and intensity is crucial for welding 4130 steel, as different thicknesses and joint configurations may require varying heat inputs.

- High Temperature Capability: A torch that can reach and maintain high temperatures is essential since 4130 has a higher carbon content and requires significant heat for effective fusion and penetration during the welding process.

- Portability and Ergonomics: Given the often intricate and confined spaces in aircraft, a gas torch that is lightweight and easy to maneuver can enhance precision and control during welding operations.

- Fuel Efficiency: A torch that maximizes fuel efficiency ensures that the welder can work longer without frequent refills, which is particularly advantageous for extensive aircraft projects.

- Durability: The torch should be constructed from high-quality materials to withstand the rigors of welding and resist wear and tear, ensuring longevity and reliability in demanding environments.

Adjustable flame control is vital because the welder must tailor the heat to the specific requirements of the 4130 steel, which can vary based on thickness and joint design. This feature allows for precision welding, minimizing the risk of warping or damaging the material.

High temperature capability is important as 4130 steel, being a medium-carbon alloy, requires temperatures that can adequately melt the base material for effective welding. A gas torch that can achieve and sustain these elevated temperatures ensures strong welds and proper fusion.

Portability and ergonomics play a significant role in the welding process, especially in the aircraft industry where technicians often work in tight spaces. A lightweight and well-designed torch allows for better control and reduces fatigue, leading to more precise welds.

Fuel efficiency is a crucial quality since it allows for longer working periods without interruptions for fuel replacement. This is particularly beneficial during extensive welding tasks on aircraft, where time efficiency is critical.

Durability is essential for a gas torch that will be used in a demanding environment like aircraft welding. A robust design ensures that the torch can withstand the physical stresses of the job, providing reliable performance over time.

Which Types of Fuel are Best Suited for Welding 4130 Steel?

The best types of fuel for welding 4130 steel include acetylene, propane, and MAPP gas.

- Acetylene: Acetylene is the most commonly used fuel for welding due to its high flame temperature, which can reach up to 3,500 degrees Celsius. This makes it particularly effective for welding high-strength steels like 4130, as it allows for fast heat application and effective fusion of the metal.

- Propane: Propane is a more economical option compared to acetylene, with a flame temperature reaching about 1,980 degrees Celsius. While it is less effective for welding applications that require very high heat, propane can still be used for preheating and for thinner sections of 4130 steel, making it a versatile choice for lighter welding tasks.

- MAPP Gas: MAPP gas, a mixture of gases including methylacetylene and propadiene, provides a flame temperature similar to that of acetylene, around 3,200 degrees Celsius. It is known for its ability to maintain a stable flame and can be used effectively for welding 4130 steel, though it is less commonly used now due to the availability of acetylene.

How Does Flame Control Impact the Quality of Welds in 4130 Steel?

Flame control is crucial for achieving high-quality welds in 4130 steel due to its specific properties and the requirements of welding techniques.

- Flame Temperature: The flame temperature directly affects the heat input to the weld area, which is vital for melting the base metals properly. For 4130 steel, maintaining the right temperature prevents overheating, which can lead to warping and undesirable metallurgical changes.

- Flame Type: Different flame types, such as neutral, carburizing, or oxidizing, influence the weld quality. A neutral flame is generally preferred for welding 4130 steel, as it provides a balanced heat without introducing excess carbon or oxygen, which could compromise the weld integrity.

- Heat Control: Effective heat control allows for better penetration and fusion of the materials. By adjusting the flame size and distance from the workpiece, welders can achieve the optimal heat distribution, reducing the risk of defects like porosity or cracks.

- Gas Composition: The type of gas used in the torch, such as acetylene or propane, affects the flame characteristics. Acetylene is often favored for its higher flame temperature, making it suitable for welding thicker sections of 4130 steel, ensuring a strong and durable weld.

- Weld Speed: The speed at which the weld is made can change the heat exposure of the steel. Controlling the travel speed ensures that the steel does not overheat or cool too quickly, which is critical for maintaining the desired mechanical properties of 4130 steel.

What Are the Top Gas Torches Recommended for Welding Aircraft 4130?

When welding aircraft 4130 steel, precision and control are paramount. A high-quality gas torch can significantly influence the quality of your work. Here are some top gas torches recommended for this specialized task:

-

Oxygen-Acetylene Torch: This traditional setup is favored for its ability to produce high temperatures up to 3,500°F (1,982°C), making it ideal for tasks involving 4130 steel. Models like the Harris 6290 are known for their durability and efficiency.

-

Bernzomatic TS8000: A popular choice for both professional welders and hobbyists, this torch features a trigger-start ignition and adjustable flame control, which allows for precise applications. Its compatibility with propane or MAPP gas enhances its versatility.

-

Victor Oxy-Fuel Torch: Renowned for reliability, Victor torches such as the Victor Performer are geared for medium to heavy welding processes. Their ergonomic design improves operator comfort during extended use.

-

Smith Equipment T-T-190: Ideal for welding thinner sections of 4130, this torch provides a focused flame that reduces warping and allows for better bead control.

Selecting the right gas torch hinges on the specific requirements of your project, such as thickness of material, type of weld, and level of portability needed.

What Safety Measures Should You Take When Utilizing a Gas Torch for Welding?

When utilizing a gas torch for welding, particularly in sensitive applications like aircraft 4130, implementing safety measures is crucial.

- Personal Protective Equipment (PPE): Always wear appropriate PPE such as flame-resistant gloves, safety goggles, and a welding helmet. This gear protects against burns, ultraviolet radiation, and flying debris that can occur during the welding process.

- Proper Ventilation: Ensure that the workspace is well-ventilated to prevent the accumulation of harmful gases or fumes. Adequate airflow reduces the risk of inhalation of toxic substances that can be released during welding.

- Secure the Work Area: Keep the work area organized and free of flammable materials. This minimizes the risk of accidental fires, as gas torches generate high temperatures that can ignite combustible substances.

- Check Equipment for Leaks: Before use, inspect gas hoses and connections for any signs of leaks. Utilizing a soapy water solution can help identify leaks, ensuring that gas is properly contained and reducing the risk of explosions.

- Use a Fire Extinguisher: Keep a class B fire extinguisher nearby, as it is suitable for flammable liquid fires. Being prepared with an extinguisher ensures that you can quickly address any fire emergencies that may arise during the welding process.

- Follow Manufacturer Guidelines: Adhere to the operating instructions provided by the gas torch manufacturer. Understanding the correct usage and limitations of the equipment ensures safe operation and optimal performance.

- Work in Pairs: Whenever possible, work with a partner to monitor the welding process. Having someone nearby can provide assistance in case of an emergency and ensures that help is readily available if something goes wrong.

How Can You Properly Maintain Your Gas Torch for Long-lasting Performance?

To ensure your gas torch remains effective and safe for welding aircraft 4130, proper maintenance is essential.

- Regular Cleaning: Keeping the torch clean is crucial for optimal performance. Residue buildup can obstruct gas flow and affect flame quality, so it’s important to clean the nozzle and tip regularly using a soft brush and appropriate cleaning solutions.

- Inspecting Connections: Regularly check the connections between the torch and the gas supply. Loose or damaged fittings can lead to leaks, which not only affect the torch’s performance but also pose safety hazards. Ensure all connections are tight and in good condition before each use.

- Checking O-Rings and Seals: The O-rings and seals in a gas torch are vital for preventing gas leaks. Inspect these components frequently for any signs of wear or damage, as a compromised seal can result in dangerous leaks and inefficient operation. Replace any worn O-rings immediately.

- Proper Gas Storage: Store your gas cylinders in a cool, dry place away from direct sunlight and heat sources. This helps to maintain the integrity of the gas and prevents pressure fluctuations that can affect performance. Always ensure that the cylinder is secured and upright during storage.

- Flame Adjustment: Regularly adjust the flame to ensure it is at the correct setting for your welding tasks. An improperly adjusted flame can result in poor welding quality or damage to the material being worked on. Familiarize yourself with the best settings for welding aircraft 4130 to achieve optimal results.

- Periodic Professional Servicing: Consider having your gas torch professionally serviced at regular intervals. A professional can identify hidden issues and perform necessary repairs or adjustments that may not be apparent during routine inspections, ensuring your torch remains in top working condition.