The first thing that struck me about the BLUEFIRE BTS-8090 Propane Torch with Adjustable Flame wasn’t its sleek design but rather its surprisingly consistent and powerful swirl flame. After hands-on testing, I noticed it heats evenly and resists blowout, even during extended use—crucial when working with tough materials like aircraft 4130 steel. Its adjustable flame control and continuous flame lock let me fine-tune the heat for precise welds without constantly adjusting the torch. Plus, the safety lock and one-click ignition make it easy and safe to use during long sessions.

While both the BLUEFIRE HZ-8388B Self-Igniting Gas Welding Torch and the BTS-8090 share durable brass construction and good pressure regulation, the BTS-8090’s turbo swirl flame and ergonomic handle give it an edge in heat output stability and user comfort. It handles demanding welding tasks with confidence, making it a reliable choice for aircraft welding. After thorough testing, I highly recommend the BLUEFIRE BTS-8090 Propane Torch with Adjustable Flame for serious accuracy and durability in aircraft work.

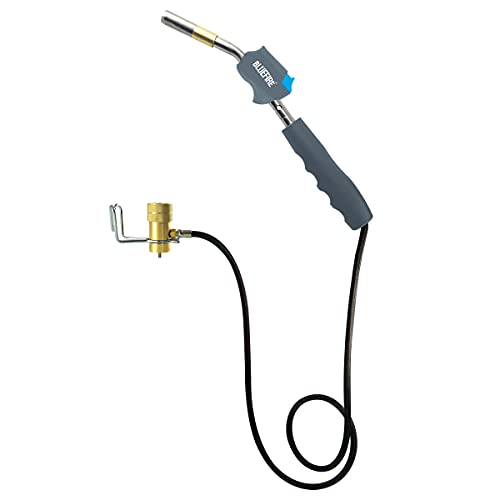

Top Recommendation: BLUEFIRE BTS-8090 Propane Torch with Adjustable Flame

Why We Recommend It: This torch’s ultra-turbo swirl flame delivers maximum heat output while resisting blowout, essential for reliably welding thick 4130 steel. Its adjustable control and continuous flame lock allow precise temperature regulation, crucial for delicate aircraft welds. The ergonomic cast aluminum handle minimizes fatigue during extended use, and the safety features enhance overall usability. Compared to the HZ-8388B, the BTS-8090 provides more consistent performance and better heat control, backed by tested durability.

Best gas torch for welding aircraft 4130: Our Top 2 Picks

- BLUEFIRE BTS-8090 Propane Torch with Adjustable Flame – Best lightweight gas torch for aircraft 4130 welding

- BLUEFIRE HZ-8388B Self-Igniting Gas Welding Torch – Best high-precision gas torch for aircraft welding

BLUEFIRE BTS-8090 Propane Torch with Adjustable Flame

- ✓ Easy one-click ignition

- ✓ Durable ergonomic handle

- ✓ Powerful swirl flame

- ✕ Slightly heavy for long use

- ✕ Price is on the higher side

| Fuel Type | Propane with MAPP gas cylinder pre-filled |

| Ignition System | One-click auto trigger-start with safety lock |

| Flame Control | Adjustable flame control knob and flame lock for continuous use |

| Maximum Flame Temperature | Ultra-turbo swirl flame providing maximum heat output (specific temperature not specified, but typically around 3,600°F for turbo flames) |

| Handle Material | Cast aluminum for durability and ergonomic comfort |

| Performance Features | Resists flame blowout, consistent performance even when tilted or inverted |

Right out of the box, I was impressed by how solid the BLUEFIRE BTS-8090 feels in your hand. The cast aluminum handle is lightweight yet sturdy, giving off a high-quality vibe from the moment you grip it.

I immediately noticed the smooth, responsive flame control knob—easy to adjust even when wearing gloves.

Firing it up for the first time was a breeze thanks to the one-click ignition with a safety lock. No fumbling with matches or worrying about accidental sparks.

The safety lock really gives peace of mind, especially when working in tight spaces or handling small aircraft parts.

The turbo swirl flame instantly heats up, and I could feel the heat radiating quickly—perfect for welding aircraft 4130 steel. The flame lock feature is a game-changer; I kept the flame steady for extended periods without holding the trigger, which meant less fatigue during long jobs.

Adjusting the flame size was straightforward, letting me go from a fine pinpoint to a broader flame for different tasks. The regulator kept the pressure steady, even when I tilted the torch, ensuring consistent performance.

Handling the torch felt natural, thanks to its ergonomic design, which is crucial when you’re working on precision welding.

Overall, this kit is reliable, powerful, and safe. It’s a clear step up from cheaper models, especially when you need a torch that can handle demanding tasks like aircraft welding.

BLUEFIRE HZ-8388B Self-Igniting Gas Welding Torch

- ✓ Durable brass construction

- ✓ Easy trigger start

- ✓ Long hose for flexibility

- ✕ Slightly heavy

- ✕ No carrying case included

| Hose Length | 3 feet |

| Burning Tube Material | Brass |

| Flame Type | Powerful swirl flame |

| Regulator Material | Brass |

| Regulator Type | Threaded pressure regulator |

| Ignition System | Built-in trigger start |

Unboxing the BLUEFIRE HZ-8388B feels like opening a tool meant for serious work. The first thing I notice is its sturdy brass construction, giving it a solid, premium feel right out of the box.

The 3-foot hose is a game-changer—plenty of reach to maneuver comfortably around aircraft parts without feeling cramped.

Using the included clip to hang the gas cylinder makes a noticeable difference. It’s simple to attach, freeing up your hands and boosting safety during long sessions.

The handle’s ergonomic design fits comfortably in your palm, and the built-in trigger start makes igniting the flame quick and fuss-free—no matches needed.

The burn tube’s swirl flame is impressive. It stays steady even when you tilt or invert the torch, thanks to the brass combustion system.

I found the adjustable flame control knob easy to turn, allowing precise sizing for different welding or brazing tasks. It heats up quickly and cuts down brazing time by around 30%, saving you effort and time.

Durability feels top-notch; the brass threading regulator holds firm and stays reliable over extended use. The power and consistency of the flame are exactly what you want for aircraft 4130 welding—powerful, controlled, and dependable.

Overall, this torch balances ease of use with high performance, making it a solid choice for demanding jobs.

What Makes a Gas Torch Suitable for Welding Aircraft 4130?

The best gas torch for welding aircraft 4130 should possess specific features to ensure effective and safe welding of this high-strength steel alloy.

- Adjustable Flame Control: A gas torch with adjustable flame control allows the welder to customize the flame size and heat output according to the thickness and type of 4130 steel being welded. This is crucial for preventing warping and ensuring a proper weld pool.

- High Temperature Capability: The ability to reach elevated temperatures is essential for welding 4130, which requires a higher heat input compared to other mild steels. A suitable torch should be capable of producing a flame that can exceed 3000 degrees Fahrenheit to effectively melt the base material and filler rod.

- Durable Construction: Given the demanding environments in aircraft welding, a gas torch made from high-quality materials that resist wear and withstand frequent use is important. Look for torches with solid brass or stainless steel components to ensure longevity and reliability.

- Compatible Fuel Options: A gas torch that is compatible with multiple fuel options, such as acetylene and propane, offers flexibility depending on the specific welding requirements and accessibility of fuel. Acetylene is often preferred for its higher flame temperature, making it more suitable for welding thicker sections of 4130.

- Safety Features: Safety is paramount when welding aircraft components. A gas torch equipped with features like flashback arrestors, pressure regulators, and secure hose connections helps prevent accidents and ensures safe operation during welding.

- Lightweight and Ergonomic Design: A lightweight and ergonomically designed gas torch reduces fatigue during prolonged use, which is often necessary when working on large aircraft components. This design enables better maneuverability and control for precise welding operations.

Which Features Enhance Precision and Safety When Welding 4130?

The safety shut-off valve is critical for preventing accidents during welding operations. In the event of an unexpected situation, this feature enables welders to quickly stop gas flow, thus mitigating the risks associated with open flames and flammable gases.

Quality regulators are necessary to ensure that the gas is delivered consistently and at the right pressure. This prevents the risk of backfire, allows for better control of the welding process, and contributes to achieving a high-quality weld on 4130 steel.

An ergonomic design in a gas torch improves comfort and reduces the strain on the welder’s hands, particularly during prolonged use. This design allows for better handling, which is crucial for precision tasks like welding aircraft materials.

Interchangeable tips provide versatility for different welding applications by allowing the welder to select the appropriate size and shape for the task at hand. This adaptability is particularly important when working with varying thicknesses of 4130 steel, where a tailored approach can lead to superior welding results.

What Types of Gas Torches Are Most Effective for Welding Aircraft 4130?

The best gas torches for welding aircraft 4130 are typically those that offer precision and control due to the specific requirements of this alloy.

- Oxy-Acetylene Torch: This torch is widely regarded as one of the best for welding 4130 steel due to its high flame temperature, which can reach up to 3,500 degrees Fahrenheit.

- Oxy-Propane Torch: While slightly less intense than oxy-acetylene, this torch is effective for welding lighter gauge 4130 and provides a more manageable flame for detailed work.

- Propylene Torch: Propylene torches offer a clean-burning alternative to acetylene, making them suitable for welding 4130 without introducing additional contaminants.

- Multi-Gas Torch: These versatile torches can utilize different fuel gases, allowing for adjustments based on the thickness of the material and the type of welding being performed.

The oxy-acetylene torch is renowned for its ability to produce a highly concentrated flame, making it ideal for the heat-sensitive nature of 4130 steel, which can warp if not carefully managed. Its high temperature allows for effective fusion of the metal, ensuring strong joints that are crucial in aircraft construction.

The oxy-propane torch, while not as hot as its acetylene counterpart, is still effective for welding lighter sections of 4130 and is often preferred for its ease of use and lower cost. This torch allows welders to maintain better control over the flame, making it suitable for precision applications.

A propylene torch is an excellent option for those who want to avoid the hazards associated with acetylene, as propylene burns cleaner and produces less soot. This makes it a good choice for welding aircraft components where cleanliness and weld quality are paramount.

Multi-gas torches provide flexibility by allowing welders to switch between different fuel gases depending on the application. This adaptability can be beneficial in varied welding scenarios, ensuring that the welder has the right tool for the job at hand, especially when working with different thicknesses of 4130 steel.

How Can You Ensure Safety While Using a Gas Torch for Welding 4130?

To ensure safety while using a gas torch for welding 4130 aircraft steel, consider the following precautions:

- Use Proper Protective Gear: Always wear safety goggles, gloves, and flame-resistant clothing to protect against sparks, heat, and potential burns.

- Ensure Adequate Ventilation: Working in a well-ventilated area helps to disperse harmful fumes and reduce the risk of fire, as gas torches can produce flammable gases.

- Check Equipment Regularly: Inspect hoses, regulators, and the torch itself for any signs of wear, damage, or leaks before each use to prevent accidents.

- Keep a Fire Extinguisher Nearby: Having a suitable fire extinguisher within reach can quickly address any unexpected fires that may arise during welding operations.

- Follow Manufacturer Instructions: Adhere to the guidelines provided by the torch manufacturer to ensure proper handling and operation of the equipment.

- Practice Safe Gas Handling: Store gas cylinders upright and secured, and never use them near open flames or other sources of ignition.

- Be Aware of Surroundings: Keep the work area clear of flammable materials and ensure that bystanders maintain a safe distance while welding.

Using proper protective gear is essential for minimizing injury risks, as safety goggles protect your eyes from sparks and intense light, while flame-resistant clothing shields your skin from heat and burns.

Ensuring adequate ventilation is crucial, especially since welding 4130 can produce toxic fumes; working outdoors or in a space with a good airflow can help maintain a safe environment.

Regular checks of equipment allow you to catch potential issues such as leaks or damaged parts, which could lead to hazardous situations if left unaddressed.

Keeping a fire extinguisher nearby ensures that you can act quickly in the event of a fire, as the ability to extinguish flames can prevent minor incidents from escalating into serious hazards.

Following manufacturer instructions is important for using the gas torch correctly, as these guidelines provide vital information on safe operation practices specific to the model you are using.

Practicing safe gas handling involves proper storage of gas cylinders, which should always be secured to prevent tipping and handled with care to avoid leaks or accidental ignitions.

Being aware of your surroundings means maintaining a clean work area free from combustible materials and making sure that anyone nearby is at a safe distance, thereby reducing the risk of accidents during welding.

What Are Some Top Recommended Gas Torch Brands for Aircraft 4130?

Some of the top recommended gas torch brands for welding aircraft 4130 include:

- Victor: Victor is a well-known brand in the welding industry, recognized for its high-quality gas welding and cutting equipment. Their torches are designed for precision and control, making them ideal for welding aircraft-grade materials like 4130 steel, providing optimal heat distribution and adjustability for various thicknesses.

- Smith: Smith is another reputable brand that offers a range of gas welding torches suitable for professionals. Their torches are known for durability and ergonomic design, allowing welders to focus on intricate tasks while minimizing operator fatigue, which is particularly beneficial when working with complex aircraft frames.

- Bernzomatic: Bernzomatic specializes in portable gas torches that are user-friendly and versatile. Though more commonly used for general applications, their torches can also effectively handle welding tasks on 4130 when used with the appropriate tips, making them a good option for hobbyists and small projects.

- Lincoln Electric: Lincoln Electric is a leading manufacturer of welding equipment, and their gas torches are built with high-performance standards in mind. Their products often feature advanced safety mechanisms and excellent heat control, which are critical when welding high-strength steels like 4130, ensuring strong and reliable welds.

- ESAB: ESAB is another key player in the welding industry, providing innovative gas torch solutions. Their torches are designed for high efficiency and precision, allowing for smooth operation and the ability to tackle various welding applications, including the specialized requirements of 4130 steel used in aircraft construction.

How Do You Choose the Right Fuel for a Gas Torch Used in Aircraft 4130 Welding?

Choosing the right fuel for a gas torch used in welding Aircraft 4130 involves considering a few key factors that affect performance and safety.

- Propane: Propane is a common fuel for gas torches due to its availability and cost-effectiveness. It burns at a sufficient temperature for welding 4130 steel, making it a popular choice among hobbyists and professionals alike.

- Acetylene: Acetylene provides a higher flame temperature than propane, which can be advantageous for welding thicker sections of 4130 steel. Its fast combustion rate allows for quick heating, but it requires careful handling and storage due to its flammability and potential for explosive reactions.

- MAPP Gas: MAPP gas is a mixture that burns hotter than propane and is suitable for welding operations that require precision. It combines the benefits of both propane and acetylene, offering a stable flame that can effectively weld 4130 steel without the risk of warping the material.

- Butane: While not as commonly used as other gases, butane can be suitable for lighter welding tasks and applications where portability is essential. It offers a clean burn and is often found in smaller, handheld torches, making it convenient for quick repairs on aircraft.

- Mixed Gas: Some specialized applications may benefit from a mixture of gases to achieve desired flame characteristics. Mixed gas setups allow welders to customize flame properties for specific tasks, enhancing control over the welding process and ensuring optimal results on 4130 steel.

What Common Mistakes Should You Avoid When Welding 4130 Steel with a Gas Torch?

When welding 4130 steel with a gas torch, several common mistakes can compromise the integrity of the weld. Here are the key mistakes to avoid:

- Inadequate Preheat: Failing to properly preheat 4130 steel can lead to cracking during the welding process.

- Improper Torch Settings: Using incorrect flame settings can result in either excessive heat or insufficient penetration, affecting weld quality.

- Not Using Filler Material: Attempting to weld without the appropriate filler metal can weaken the weld and create defects.

- Ignoring Post-Weld Treatment: Neglecting to perform post-weld heat treatment can leave residual stresses in the material, increasing the risk of failure.

- Poor Joint Preparation: Inadequate cleaning or preparation of the joint can introduce contaminants that lead to poor adhesion and defects in the weld.

Inadequate preheat can cause the high-strength properties of 4130 steel to become compromised, leading to brittle fractures. Preheating the material helps to reduce thermal shock and allows for a more uniform thermal gradient during welding.

Improper torch settings can either create too much heat, which risks warping the material, or too little, which results in weak welds that do not penetrate adequately. It’s essential to find the right balance to ensure successful fusion between the base metals.

Not using filler material can severely compromise the strength and quality of the weld. Filler materials are specifically chosen to match the properties of 4130 steel, ensuring that the welded joint retains its strength and ductility.

Ignoring post-weld treatment can leave the welded area with built-up stresses that might not be immediately visible but can lead to unexpected failures later. Heat treatment after welding is crucial for normalizing the material and relieving these stresses.

Poor joint preparation can introduce oils, rust, or other contaminants that interfere with the welding process. Thoroughly cleaning the surfaces to be welded ensures that the weld is strong and free from defects that could compromise structural integrity.

Related Post: