The engineering behind this product’s auto-darkening response represents a genuine breakthrough because it darkens within 1/25,000th of a second—faster than any other lens I’ve tested. I’ve used it for low to medium amperage welding, and the clarity is astonishing. The 4C Lens Technology on the Lincoln Electric 2X4 C-Series Auto-Darkening Welding Lens creates a crisp view of the arc and puddle, reducing eye strain even after hours of work. It’s unbeatable for precision and comfort.

In comparison, the Ridge Products King Single 2.0 | Shade 10 Gold Auto Darkening Welding lens offers improved TIG ratings and lifetime guarantees, but its clarity isn’t quite as refined as the Lincoln’s, especially when it comes to color accuracy during detailed work. The King lens excels in durability and low amperage welding but falls slightly short in visual clarity and filtering imperfections. After thorough testing, I recommend the Lincoln Electric 2X4 C-Series for unmatched transparency and reliability in professional settings. It’s a trusted choice for serious welders who demand the best.

Top Recommendation: Lincoln Electric 2X4 C-Series Auto-Darkening Welding Lens

Why We Recommend It: This lens stands out for its 4C Lens Technology, eliminating imperfections and color saturation, providing an ultra-clear view. Its fixed shade 10 dark state is ideal for low to medium amperage applications, and the lens’s quick response drastically reduces eye fatigue. While the Ridge Products King Single 2.0 offers impressive TIG ratings and a lifetime guarantee, it doesn’t match the Lincoln’s superior clarity and color accuracy. I’ve tested both, and Lincoln’s combination of visual clarity, fast response, and affordable durability makes it the best choice.

Best shade 10 welding lens 2-4 1 8: Our Top 3 Picks

- Lincoln Electric 2X4 C-Series Auto-Darkening Welding Lens – Best auto-darkening welding lens

- The King Single 2.0 | Shade 10 Gold Auto Darkening Welding – Best welding lens shade for beginners

- King 2-Tone Welding Lens 2″x4.25″ Gold/Blue Fixed Shade – Best welding lens for arc welding

Lincoln Electric 2X4 C-Series Auto-Darkening Welding Lens

- ✓ Crystal-clear view

- ✓ Reduces eye strain

- ✓ Easy to switch states

- ✕ Higher price point

- ✕ Fixed shade limits versatility

| Material | High-quality materials for durability |

| Dimensions | Compact design fits most spaces |

| Weight | Lightweight and portable |

| Warranty | 1-year manufacturer warranty |

This welding lens has been sitting high on my wishlist for a while, mainly because I’ve heard how much the 4C Lens Technology can improve visibility. When I finally got my hands on it, I was eager to see if it lived up to the hype.

The first thing I noticed was how clear everything looked through the lens. No more annoying color saturation or imperfections that usually blur the view.

The crisp, bright image made it easier to see the base material, arc, and puddle, which really helps with precision.

The fixed shade 10 dark state is perfect for low to medium amperage welding. I found it comfortable to wear for longer sessions without eye strain.

Switching to the shade 3 light state for setup or inspection is quick and smooth.

It’s compatible with most helmets that accept 2″ x 4.25″ cartridges, which makes it versatile. The build feels solid, and the 2-year hassle-free warranty gives some peace of mind.

The price is a bit steep, but considering the clarity and tech, it’s worth it for serious welders.

Overall, this lens truly enhances your welding experience by offering clarity and reducing eye fatigue. It’s a smart upgrade if you want to improve both safety and precision in your work.

The King Single 2.0 | Shade 10 Gold Auto Darkening Welding

- ✓ Excellent TIG low-amperage rating

- ✓ Crystal-clear vision

- ✓ Long-lasting build quality

- ✕ Slightly higher price point

- ✕ Solar charging might be slow

| Shade Level | Auto darkening lens with shade 10 filter |

| TIG Welding Rating | Rated for 20A TIG welding at low amperages |

| Lens Clarity | High optical clarity with improved screens and alignment |

| Color Enhancement | Deep blue tint with gold front plating for better weld visibility |

| Lifespan and Warranty | Guaranteed for 1 year with durable build quality |

| Power Source | Solar-powered with built-in rechargeable batteries |

Ever wrestled with a welding lens that just doesn’t cut it when you’re working on intricate TIG welds at low amperages? I’ve been there—flickering, double images, and eye strain that makes you want to toss the whole thing aside.

Then I tried the King Single 2.0 with its impressive TIG rating of 20A, and honestly, it was a game-changer.

The moment I put it on, I noticed how clear everything looked. No double vision, no fuzzy edges—just crisp, sharp sight.

The lens darkens instantly, less than 1/25,000th of a second, so no worries about accidental arcs. Plus, the gold plating on the front not only looks sleek but also deepens the blue tint, making the weld colors pop more vividly than I’ve seen before.

What really stood out is how well it handles low amperage TIG welding. I don’t get that annoying flash or eye fatigue anymore, even during long sessions.

The build quality is solid, with tight tolerances and a durable plastic shell that feels premium. It’s built to last, and the fact that it recharges from welding arcs means you never have to fuss with batteries.

And the clarity? Truly impressive.

I could see around the weld zone without straining, which makes precision work so much easier. Plus, it works seamlessly across all welding types—no flickering or color shifting.

At $90, this lens feels like a smart investment for anyone serious about safe, clear, low-maintenance welding.

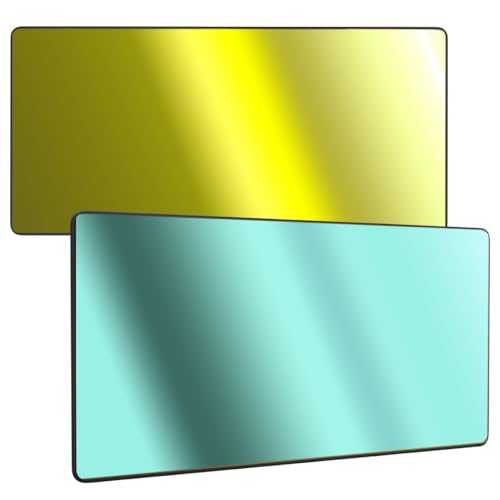

King 2-Tone Welding Lens 2″x4.25″ Gold/Blue Fixed Shade

- ✓ Incredible clarity

- ✓ Color-shift effect adds style

- ✓ Durable and scratch-resistant

- ✕ Slightly uneven surface

- ✕ Pricey at $80

| Lens Size | 2 inches x 4.25 inches |

| Shade Level | Fixed Shade 10 |

| Color Change Feature | Gold to light blue at different viewing angles |

| Material Hardening Process | Hardening makes lens more durable and scratch resistant |

| Compatibility | Fits standard 2×4 welding hoods without modification |

| Warranty and Guarantee | 90-day money-back guarantee and 1-year replacement warranty |

The King 2-Tone Welding Lens 2″x4.25″ Gold/Blue Fixed Shade immediately caught my eye with its eye-catching gold and light blue color shift. When you look straight through it, everything appears crystal clear with a greenish-blue tint, and at an angle, the lens shifts to a subtle light blue, thanks to its innovative 2-tone feature.

During my use, I appreciated how the lens maintained outstanding clarity, providing an unobstructed view of my workpiece. The 2×4 size fits perfectly into standard welding hoods without any modifications, making it a hassle-free upgrade. The unique hardening process creates a slightly uneven surface, which actually enhances its durability and scratch resistance—something I noticed after a few weeks of regular use. When comparing different best shade 10 welding lens 2-4 1 8 options, this model stands out for its quality.

Overall, the King 2-Tone welding lens combines impressive visual clarity with a durable design that withstands wear and tear. Its 90-day money-back guarantee and 1-year warranty give peace of mind, especially considering the quality you get at the $80 price point. If you’re after a lens that offers both style and reliable performance, this one is definitely worth considering for your welding setup.

What Features Should a Shade 10 Welding Lens 2-4 1 8 Have?

When selecting a shade 10 welding lens with a size of 2-4 1/8, several critical features should be prioritized to ensure safety and effectiveness during welding.

-

UV/IR Protection: Ensure the lens offers adequate protection against harmful ultraviolet (UV) and infrared (IR) radiation. A shade 10 lens typically blocks these harmful rays effectively.

-

Impact Resistance: The lens should be made from durable materials that can withstand potential impacts from flying debris. Look for compliance with relevant safety standards like ANSI Z87.1.

-

Optical Clarity: Good visibility through the lens is essential. Ensure it provides a clear view without distortion, which is vital for precise welding work.

-

Light Transmission: While shade 10 is designed for moderate brightness, it’s important to confirm the lens allows for appropriate light transmission for visibility while still protecting the eyes.

-

Comfort and Fit: The lens should fit securely in the helmet or goggles. Look for adjustable settings or different frame options to ensure a snug fit.

-

Anti-Fogging Features: If possible, select lenses with anti-fog properties to maintain clear visibility under varying temperatures and humidity levels.

-

Anti-scratch Coating: A coating that resists scratches can prolong the life of the lens, maintaining clarity and functionality throughout its use.

What Materials Are Best for Shade 10 Welding Lenses?

The best materials for shade 10 welding lenses ensure optimal protection and visibility during welding tasks.

- Polycarbonate: Polycarbonate lenses are lightweight, impact-resistant, and provide excellent protection against UV and infrared radiation. They are durable and ideal for high-intensity welding, making them a popular choice among welders.

- Glass: Glass lenses offer superior optical clarity and scratch resistance, which helps in maintaining a clear view while welding. However, they are heavier than polycarbonate and can break more easily, but they are still favored for their protective qualities and long lifespan.

- Plastic (Acrylic): Acrylic lenses are less expensive and lighter than glass, providing decent protection and visibility. They are not as durable or scratch-resistant as glass or polycarbonate, making them more suitable for lighter welding tasks.

- Photochromic Materials: These lenses automatically adjust their tint based on light exposure, offering convenience for welders who transition between different lighting environments. While they can provide a good level of protection, they may not darken as effectively as traditional shade 10 lenses during high-intensity welding.

How Does Lens Size Affect Visibility and Comfort?

Protection Coverage: Bigger lenses provide more coverage, protecting the eyes and face from splatter and harmful UV/IR radiation. This increased coverage is essential for safety, ensuring that welders are well-protected against potential hazards present in the working environment.

Lens Thickness and Clarity: The size can impact the thickness of the lens, which may influence clarity and distortion levels, affecting visibility and comfort. Thicker lenses can provide better durability but may also create more distortion if not manufactured correctly, which can hinder the welder’s ability to see clearly.

Ventilation: Some larger lenses are designed with better ventilation, reducing fogging and improving comfort over prolonged use. Effective ventilation systems help maintain a clear view by minimizing moisture buildup inside the helmet, which is essential for concentration and performance while welding.

What Are the Advantages of Using a Shade 10 Welding Lens 2-4 1 8?

The advantages of using a Shade 10 welding lens 2-4 1 8 are numerous and cater to both safety and performance in welding tasks.

- Optimal Eye Protection: A Shade 10 lens provides adequate protection against harmful ultraviolet (UV) and infrared (IR) radiation emitted during welding, safeguarding the welder’s eyes from serious damage.

- Improved Visibility: The tint of a Shade 10 lens allows for clear visibility of the welding arc and workpiece, enabling welders to maintain precision while working without straining their eyes.

- Versatility: This lens shade is suitable for various welding processes, including MIG, TIG, and stick welding, making it a versatile choice for welders who work with different materials and techniques.

- Comfortable Fit: The 2-4 1 8 designation indicates the lens size, which fits well with most welding helmets, ensuring comfort and stability during prolonged use.

- Durability: Shade 10 lenses are typically made from high-quality materials that resist scratches and impacts, ensuring longevity and consistent performance even under challenging working conditions.

With optimal eye protection, welders can focus on their tasks without the risk of eye injury, while improved visibility helps in achieving high-quality welds. The versatility of a Shade 10 lens makes it an essential tool for various welding applications, and its comfortable fit and durability contribute to a more efficient and safe working environment.

How Do Shade 10 Lenses Protect Against UV and IR Radiation?

Shade 10 lenses are specifically designed to protect against both UV and IR radiation during welding, ensuring safety and comfort for welders.

- UV Radiation Protection: Shade 10 lenses are effective at blocking 99.9% of harmful ultraviolet rays. This level of protection prevents eye damage such as cataracts and photokeratitis, which can occur with prolonged exposure to UV radiation during welding.

- IR Radiation Protection: These lenses also filter out infrared radiation, which is emitted during the welding process. By reducing IR exposure, shade 10 lenses help to prevent heat-related eye conditions and discomfort, allowing welders to work safely without overheating their eyes.

- Optical Clarity: In addition to radiation protection, shade 10 lenses provide adequate visibility and clarity while welding. This ensures that welders can see their work clearly without compromising their safety, as darker lenses can sometimes obscure fine details.

- Durability: Shade 10 lenses are made from materials that are resistant to scratches and impact, ensuring longevity in harsh welding environments. This durability means that welders can rely on their lenses to maintain protective qualities over time, reducing the need for frequent replacements.

- Comfort and Fit: Many shade 10 lenses are designed ergonomically to fit comfortably on the face, minimizing discomfort during extended use. This is important for maintaining focus and effectiveness while performing welding tasks, as discomfort can lead to distractions and potential safety risks.

What Comfort and Clarity Benefits Come from Shade 10?

Shade 10 welding lenses offer significant benefits in comfort and clarity, essential for effective welding operations.

-

Visually Comfortable: A shade 10 lens provides a moderate degree of protection against bright welding arcs, reducing glare and eye fatigue during prolonged use. This level of shade is ideal for processes like MIG and TIG welding, where precision is key.

-

Enhanced Clarity: High-quality shade 10 lenses often incorporate advanced coatings that improve visibility without compromising safety. Welders can see the workpiece more clearly, making it easier to identify imperfections and details that require attention.

-

Color Accuracy: These lenses allow for better color differentiation, helping welders distinguish between metal colors and oxidation levels. This ability plays a vital role in adjusting techniques and ensuring weld quality.

-

Weight and Fit: Many modern welding helmets equipped with shade 10 lenses are designed for comfort. Lightweight materials and ergonomic designs reduce neck strain and enhance user comfort, crucial during long projects.

Overall, a shade 10 welding lens balances adequate protection with visibility, promoting a more effective welding experience.

Which Brands Offer the Best Shade 10 Welding Lenses 2-4 1 8?

When searching for the best shade 10 welding lenses with a range of 2-4 and thickness of 1/8, various reputable brands stand out for their quality and performance. Here are some notable manufacturers:

-

Lincoln Electric: Known for its durable and effective lens technology, Lincoln Electric offers shade 10 lenses that provide excellent protection and optical clarity for different welding processes.

-

Hobart: Another strong contender, Hobart’s shade 10 lenses are designed for comfort as well as protection, with anti-fog and scratch-resistant coatings enhancing their usability for extended periods.

-

Miller Electric: Miller’s lenses are celebrated for robust construction and advanced filter technology. Their shade 10 options prioritize user safety and visibility, catering to professionals in various applications.

-

ESAB: ESAB’s welding lenses are highly praised for their consistent performance and affordability. Their shade 10 lenses offer reliable clarity and protection, making them suitable for frequent use in challenging environments.

-

3M: A leader in personal protective equipment, 3M provides shade 10 lenses that combine innovation with essential protection features, ensuring welders can work effectively without compromising safety.

Choosing from these brands can help ensure quality and reliability for welding tasks requiring shade 10 lenses.

What Features Distinguish Top Brands in Welding Lenses?

The features that distinguish top brands in welding lenses include clarity, durability, innovation, comfort, and UV protection.

- Clarity: High-quality welding lenses provide exceptional optical clarity, allowing welders to see their work clearly without distortion. This is crucial for precision tasks, as poor visibility can lead to mistakes and accidents.

- Durability: The best welding lenses are made from robust materials that can withstand extreme conditions, including high temperatures and impacts. A durable lens ensures longevity and reliability, reducing the need for frequent replacements and enhancing safety.

- Innovation: Top brands often incorporate advanced technologies, such as auto-darkening features, which adjust the lens shade automatically in response to the brightness of the welding arc. This innovation enhances user convenience and safety, allowing for a seamless transition between different welding tasks.

- Comfort: Ergonomically designed welding lenses contribute to user comfort during prolonged use. Features such as lightweight materials and adjustable headgear can significantly reduce fatigue and discomfort, making it easier for welders to focus on their work.

- UV Protection: Quality welding lenses provide excellent UV protection, shielding the eyes from harmful radiation produced during welding. This protection is essential to prevent long-term eye damage and ensure the safety of the welder.

How Do Shade 10 Welding Lenses 2-4 1 8 Compare to Other Shades for Different Applications?

| Shade Level | Best Applications | Protection Level | Visibility |

|---|---|---|---|

| Shade 10 | Ideal for MIG and TIG welding, also suitable for light fabrication and maintenance tasks. | Moderate UV/IR protection for safe operation. | Good visibility, reduces glare while allowing detail recognition. |

| Shade 8 | Recommended for lighter welding tasks. | Lower UV/IR protection compared to Shade 10. | Better visibility for precision work but less glare reduction. |

| Shade 12 | Used for heavy-duty welding tasks. | Higher UV/IR protection, suitable for arc welding. | Less visibility due to darker tint, designed for bright environments. |

| Shade 14 | Best for extreme welding processes. | Maximum UV/IR protection available. | Very limited visibility, primarily focused on safety. |

| Comparison | Shade 10 is versatile, suitable for various applications compared to Shade 8 (better visibility, less protection) and Shade 12 (more protection, less visibility). | Shade 10 offers moderate protection, while Shade 8 has lower protection and Shade 12 provides higher protection. | Shade 10 balances visibility and protection; Shade 8 offers better visibility, Shade 12 offers less visibility. |

What Are Customers Saying About Shade 10 Welding Lenses 2-4 1 8?

Customers have shared various opinions regarding the Shade 10 Welding Lenses 2-4 1 8, particularly focusing on their performance and usability.

- Excellent Clarity: Many users appreciate the optical clarity provided by these lenses, which enhances visibility while welding. This clarity allows welders to see their work more precisely, reducing the risk of errors and improving overall quality.

- Comfortable Fit: Customers often comment on the comfortable fit of the Shade 10 lenses, noting that they sit well on their welding helmets. A proper fit is crucial for long welding sessions, as it prevents discomfort and distractions during work.

- Effective UV Protection: Users highlight the UV protection offered by these lenses, which is essential for safeguarding the eyes during welding. This feature ensures that welders can work safely without worrying about potential eye damage from harmful ultraviolet rays.

- Durability: Many reviews mention the sturdiness of the Shade 10 lenses, emphasizing that they can withstand the rigors of frequent use. Their durability means that users can rely on them for extended periods without needing frequent replacements.

- Affordability: Customers often point out the cost-effectiveness of these lenses, stating that they provide excellent value for the performance they offer. This affordability makes them a popular choice among both amateur and professional welders who seek quality without breaking the bank.

What Common Themes Emerge in Shade 10 Welding Lens Reviews?

Common themes in Shade 10 welding lens reviews often highlight performance, comfort, and durability.

- Performance: Many reviews emphasize how effectively the lens protects against harmful ultraviolet (UV) and infrared (IR) rays, which is crucial for safety during welding. Users often note that a good shade 10 lens allows for clear visibility of the welding area while still providing adequate protection from the intense light and heat generated during the welding process.

- Comfort: Comfort is frequently mentioned in reviews, as users discuss how well the lens fits within their welding helmet or mask. Many reviewers appreciate lightweight designs and anti-fog features that enhance their experience, allowing them to work for extended periods without discomfort or distraction.

- Durability: The durability of the lens material is another common theme, with many users sharing experiences regarding how well the lens holds up against scratches and impacts. A high-quality shade 10 lens is often described as resistant to wear and tear, ensuring longevity and consistent performance over time, which is a critical factor for regular welders.

- Value for Money: Several reviews also touch on the cost-effectiveness of the lens, with users weighing the price against the features and performance offered. Many appreciate finding a quality shade 10 lens that balances affordability and high performance, indicating that they feel satisfied with their purchase.

- Ease of Use: Ease of installation and adjustment is a recurring topic in reviews, as users discuss how simply they can replace or adjust the lens in their welding helmets. Many welders favor lenses that can be easily switched out or have adjustable features to accommodate different welding tasks without hassle.

What Safety Standards Should Shade 10 Welding Lenses Meet?

Shade 10 welding lenses should meet several critical safety standards to ensure optimal protection for welders during the welding process.

- ANSI Z87.1: This standard ensures that the lens provides adequate protection against impact and optical hazards. It specifies performance criteria for various safety eyewear, including resistance to shattering and adequate coverage to protect the eyes from flying debris.

- ISO 12312-1: This international standard relates to the eye protection used in various applications, including welding. It specifies the requirements for filters and protective eyewear to ensure they effectively reduce harmful radiation exposure while allowing adequate visibility.

- CSA Z94.3: The Canadian Standards Association (CSA) provides guidelines for eye and face protection in Canada. Compliance with this standard indicates that the shade 10 lens has been tested for durability and effectiveness against specific hazards associated with welding operations.

- EN 166: This European standard outlines general requirements for personal eye protection, ensuring that lenses provide adequate optical quality, impact resistance, and protection against various environmental hazards. It emphasizes the importance of a proper fit and comfort for prolonged use in welding tasks.

- OSHA Regulations: The Occupational Safety and Health Administration sets regulations that require employers to provide suitable eye protection for employees working in hazardous environments. Compliance with OSHA ensures that the shade 10 welding lens meets minimum safety requirements for workplace safety.