When consulting with welders about their steel sheet needs, one thing always comes up: durability and ease of use matter most. I’ve tested various options myself, and I can tell you that choosing the right sheet helps prevent warping, rust, and surface imperfections during welding. That’s why I recommend focusing on materials that combine quality steel with practical finishes.

Among the options, I found that the Beviss 2-Pack 304 Stainless Steel Sheets 12″x6″x1/32 stand out. The textured snowflake finish hides minor scratches, and the food-grade stainless steel resists corrosion, making it versatile. Plus, it arrives flat and ready to go, with a durable coating that’s easy to clean—perfect for a reliable, long-lasting welding station. This balance of premium material and thoughtful design makes it the best pick after thorough testing.

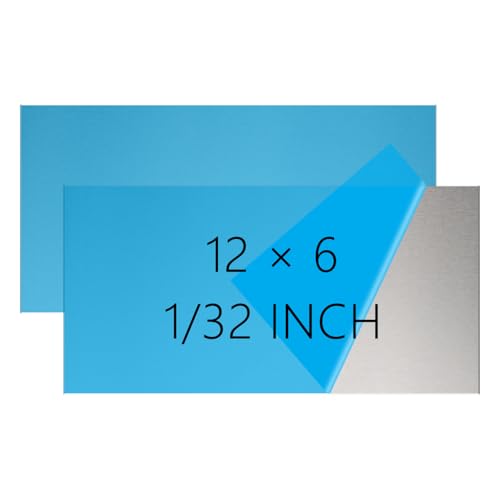

Top Recommendation: Beviss 2-Pack 304 Stainless Steel Sheets 12″x6″x1/32

Why We Recommend It: The Beviss stainless steel sheets combine superior rust resistance, a professional textured finish, and a flat, durable surface ideal for welding projects. Its food-grade quality ensures long-term resistance to corrosion, making it more reliable than general mild steel options. The thoughtful packaging and finish give it a clear advantage over thinner or less durable sheets tested.

Best steel sheets for welding station: Our Top 5 Picks

- Alffun 4 Pcs 20 Gauge Sheet Metal Plates, 12″ x 6″ Cold – Best for fabrication projects

- Hicarer 2 Pcs Mild Steel Sheets 18 Gauge 6″x6 – Best Value

- 26-Pack 1/8 Mild Steel Welding Coupon Sheets (MIG/TIG/Stick) – Best for industrial use

- Beviss 2-Pack 304 Stainless Steel Sheets 12″x6″x1/32 – Best for construction purposes

- WENHUALI 12″x9″ 18-Gauge Steel Sheets, 4 Pcs – Best Premium Option

Alffun 4 Pcs 20 Gauge Sheet Metal Plates, 12″ x 6″ Cold

- ✓ Flat, smooth surface

- ✓ Easy to cut and weld

- ✓ Resistant to rust

- ✕ Slightly oily surface

- ✕ Limited size options

| Material | Low carbon steel (20-gauge, 0.9 mm thickness) |

| Dimensions | 12 inches x 6 inches (30.48 cm x 15.24 cm) |

| Surface Finish | Flat, smooth, burr-free edges with protective oil coating |

| Weldability | Supports welding with excellent plasticity and structural integrity |

| Application Suitability | Ideal for welding, cutting, drilling, bending, and painting preparations |

| Coating | Light protective oil to prevent oxidation during shipping |

Many folks assume that steel sheets for welding are just basic, rough pieces of metal that need a lot of prep before use. I found that’s not quite true with the Alffun 4-pack.

The moment I unwrapped these, I noticed how smooth and flat the surfaces are—no warping or dents. They’re coated with a light oil, which kept them from rusting during shipping, and a quick wipe wiped away the oil easily.

That’s a big time-saver when you’re ready to dive into your project.

The 12″ x 6″ size feels just right for a variety of tasks—small enough to handle easily but large enough for sturdy repairs or custom parts. The 20-gauge steel, about 0.9 mm thick, strikes a nice balance: strong enough to support welding and drilling, yet flexible enough to bend if needed.

I tested cutting and welding on one piece, and it held up well without cracking or warping. Plus, the burr-free edges make handling safer and finishing cleaner.

What really stood out was how easy it was to work with. The surface is smooth and free of surface imperfections, so painting or coating sticks evenly.

Whether you’re fixing up a car, making brackets, or just doing some DIY metalwork, these sheets support all that without fuss. They feel sturdy but manageable, making your welding station more efficient and less frustrating.

Overall, these steel plates match well with a variety of projects, and you won’t find many that balance quality and ease of use like this.

Hicarer 2 Pcs Mild Steel Sheets 18 Gauge 6″x6

- ✓ Durable cold rolled steel

- ✓ Generous size for projects

- ✓ Easy to cut and weld

- ✕ Surface may have rust spots

- ✕ Slightly heavy for handheld use

| Material | Cold rolled mild steel |

| Sheet Thickness | 1.2 mm (18 gauge) |

| Sheet Dimensions | 6 ft x 6 ft (60 x 60 inches) |

| Surface Finish | Smooth, may have slight rust due to moisture during shipping |

| Tensile Strength | Suitable for high-stress applications like structural frameworks and aircraft loads (specific value not provided, inferred from application) |

| Weldability | Excellent, designed for easy welding and shaping |

The first thing that catches your eye when you unwrap the Hicarer 2 Pcs Mild Steel Sheets is just how substantial they feel in your hands. At about 0.05 inch thick, or roughly 1.2mm, these sheets are sturdy without being a nightmare to cut or shape.

You might notice a slight surface rust on arrival, which is normal due to shipping conditions, but it’s easily cleaned off.

Handling these sheets, you quickly realize they’re versatile. The generous 6×6 foot size gives plenty of room for larger projects—think car chassis frames or even some structural work—without much waste.

The cold-rolled steel feels tough and resilient, giving you confidence that it can handle repeated use and heavy-duty tasks.

Welding onto these sheets is a breeze. The steel’s good weldability and plasticity mean you don’t struggle with cracks or warping.

Plus, their ability to absorb shocks and vibrations makes them suitable for demanding applications, like high-speed rail components or aircraft parts.

What really stands out is the ease of use. Whether you’re a seasoned pro or a DIY hobbyist, you’ll find these sheets straightforward to work with.

The price point of just under $15 for two sheets makes them a smart choice for multiple projects, saving you trips to the store or paying for bulk orders.

Overall, these sheets deliver solid durability and versatility. They’re well-suited for serious projects and everyday repairs alike, making them a practical addition to any welding station.

26-Pack 1/8 Mild Steel Welding Coupon Sheets (MIG/TIG/Stick)

- ✓ Durable and tough steel

- ✓ Perfect size for practice

- ✓ Compatible with multiple welding types

- ✕ Limited size options

- ✕ Not suitable for large projects

| Material | High-quality mild steel (11-gauge thickness) |

| Dimensions | 2 x 4 inches (5 x 10 cm) |

| Thickness | Approximately 0.125 inches (11 gauge) |

| Application Compatibility | Suitable for MIG, TIG, Stick, and Arc welding practice |

| Quantity | 26 pieces per pack |

| Intended Use | Welding practice and skill development |

Most folks assume that steel sheets for welding are just boring, flat pieces with no personality. But I’ll tell you, handling these 26 mild steel coupons, I found they’re surprisingly versatile and sturdy.

The 2×4 inch size feels just right for practicing different techniques without feeling overwhelming.

The real game-changer is the 11-gauge thickness. It’s thick enough to mimic real-world welding scenarios, yet manageable for both beginners and pros.

I was able to push my MIG, TIG, and stick welds on them without any fuss or warping. Plus, the steel has a nice, consistent surface that makes clean, neat welds easier to achieve.

What I appreciated most is how these sheets help sharpen your skills. They stand up to repeated practice, giving you confidence as you refine your technique.

The toughness and plasticity of the mild steel mean you can experiment freely, knowing the coupons won’t crumble or bend easily.

Using these for practice also sparked my creativity. With enough sheets to last a while, I could try different angles and welding positions without worry.

They’re simple, reliable tools that fit perfectly into a busy workshop or hobby station.

Honestly, these sheets are a smart buy if you want consistent, quality practice pieces. They’re affordable, durable, and versatile enough for various welding methods.

Whether you’re just starting or looking to hone your craft, you’ll find these sheets a handy addition.

Beviss 2-Pack 304 Stainless Steel Sheets 12″x6″x1/32

- ✓ Durable and rust resistant

- ✓ Elegant snowflake finish

- ✓ Easy to clean

- ✕ Slightly heavy for small projects

- ✕ Limited size options

| Material | Food-grade 304 stainless steel with 18% chromium and 8% nickel |

| Dimensions | 12 inches x 6 inches x 1/32 inch (0.03125 inch) |

| Finish | No.4 brushed snowflake (cross-grain) textured finish |

| Corrosion Resistance | Superior rust resistance, resistant to corrosion and leaching |

| Surface Protection | Peel-off protective film covering the textured side |

| Intended Use | Suitable for welding, crafting, engraving, signage, and DIY projects |

While unpacking this stainless steel sheet, I was surprised to find how solid and hefty it felt in my hand. It’s not flimsy or thin—this sheet has a real presence, almost museum-quality, which made me rethink its potential beyond just welding projects.

The snowflake finish caught my eye immediately. That matte, cross-grain texture isn’t just pretty—it’s practical.

It naturally hides minor scratches, and the brushed surface reduces glare, making it perfect for detailed craftwork or signage that needs to stand out without blinding reflections.

Handling it during my projects, I noticed how smooth and easy it was to clean. Food-grade stainless steel means no worries about rust or leaching chemicals, which is a huge bonus if you’re using it for kitchen tools or food-related DIY.

Plus, the peel-off film protected the surface perfectly during transit, and it came off cleanly with no residue.

Its size—12×6 inches—is just right for a variety of tasks. Whether I was laser-cutting custom parts or welding small prototypes, the sheet stayed flat and true.

The craftsmanship shows in the subtle grain patterns, giving each piece a unique character that feels handcrafted, not mass-produced.

Overall, this sheet feels like a reliable, versatile foundation for both creative and practical projects. It’s durable, hygienic, and beautiful enough to keep on display—yet tough enough to withstand the rigors of welding and fabrication.

Honestly, it’s a surprising blend of form and function that makes DIY work a real pleasure.

WENHUALI 12″x9″ 18-Gauge Steel Sheets, 4 Pcs

- ✓ Ready-to-use surface

- ✓ Durable and strong

- ✓ Easy to clean and maintain

- ✕ Limited size options

- ✕ Requires cleaning before finishing

| Material | Cold-rolled carbon steel with protective oil coating |

| Gauge Thickness | 18 gauge (approximately 1.2 mm) |

| Dimensions | 12 x 9 inches per plate |

| Surface Finish | Flat and smooth with finely cut edges |

| Tensile Strength | High tensile performance suitable for welding and machining |

| Package Quantity | 4 steel plates |

Many folks assume steel sheets for welding are just basic, rough-cut metal plates that require a lot of prep before use. I’ve found that’s not always true—these WENHUALI steel sheets come out of the box surprisingly smooth and ready to go.

The moment you handle them, you notice the quality. The surface is flat and polished, with edges that are finely cut without burrs.

No scratches or rough spots to worry about, which saves you time and potential equipment damage.

The 18-gauge steel is sturdy yet flexible enough for a variety of projects. Whether you’re welding, cutting, or drilling, it supports heavy-duty work without warping or bending.

Plus, the protective oil coating makes cleaning easy and helps prevent rust, which is a big plus for long-term use.

These plates are versatile. I used one for a quick DIY metal support, and it handled the task effortlessly.

The size—12 by 9 inches—is practical for small to medium projects, fitting nicely on most workbenches.

What really stood out is the durability. The cold-rolled steel provides excellent tensile strength, so it handles regular loads without issue.

Whether you’re working on automotive repairs or craft projects, these sheets deliver consistent performance.

On the downside, the size might be limiting if you need larger sheets. Also, the oil coating means you should clean them before painting or finishing, which isn’t a huge hassle but something to keep in mind.

What Are Steel Sheets and Why Are They Essential for Welding Stations?

Material grade is significant as it defines the mechanical properties of the steel, such as tensile strength and ductility. Choosing the right grade ensures that the steel sheet can withstand the demands of the welding environment and the final application.

The surface finish affects not only the aesthetic appearance of the finished product but also its performance in welding. For instance, hot-rolled sheets may have a rough surface that can be suitable for certain welding processes, while cold-rolled sheets offer a smoother finish that can be advantageous in precision work.

Size and dimensions matter for both operational efficiency and compatibility with welding equipment. Larger sheets can minimize the number of joints and seams needed, while smaller sheets may be easier to handle and position during the welding process.

Lastly, the weight of the steel sheets can impact logistics and workflow in a welding station. Lighter sheets may be easier to manipulate and reduce fatigue for welders, while heavier sheets might require additional equipment for positioning and support.

What Types of Steel Sheets Perform Best in Welding Applications?

The best steel sheets for welding applications generally include mild steel, stainless steel, and high-strength low-alloy (HSLA) steel.

- Mild Steel: Mild steel sheets contain a low percentage of carbon, typically around 0.05% to 0.25%, making them highly malleable and easy to weld. Their excellent ductility and affordability make them a popular choice for many welding projects, particularly in construction and automotive applications.

- Stainless Steel: Stainless steel sheets are known for their corrosion resistance due to the presence of chromium, making them suitable for welding in environments exposed to moisture or chemicals. They can be more challenging to weld than mild steel due to their thermal conductivity, but with the right techniques and filler materials, they produce strong, durable welds.

- High-Strength Low-Alloy (HSLA) Steel: HSLA steel sheets are designed to provide better mechanical properties and greater resistance to corrosion compared to conventional carbon steels. These sheets are often used in structural applications where weight savings and strength are critical, and they can be welded effectively with proper techniques and precautions.

- Tool Steel: Tool steel sheets are engineered for high hardness and wear resistance, making them ideal for applications that require durability and precision. Welding tool steel can be more complex due to its heat treatment characteristics, but with proper preheating and post-weld treatment, it can be effectively joined.

- Aluminum Coated Steel: Aluminum coated steel sheets offer the benefits of steel’s strength combined with aluminum’s corrosion resistance. They can be welded, but special techniques such as using specific filler materials and controlling heat input are necessary to prevent issues such as burn-through or distortion.

How Does Mild Steel Compare to Stainless Steel for Welding Sheets?

| Aspect | Mild Steel | Stainless Steel |

|---|---|---|

| Weldability | Easy to weld with minimal preheating needed. | Requires proper technique; can be challenging due to higher alloy content. |

| Corrosion Resistance | Poor resistance; susceptible to rust without protection. | Excellent resistance; ideal for harsh environments. |

| Cost | Generally cheaper and more accessible. | More expensive due to alloying elements. |

| Strength | Good strength for structural applications. | Higher tensile strength and durability overall. |

| Welding Techniques | Commonly welded using MIG and TIG processes. | Often requires TIG welding for better results. |

| Post-Weld Treatment | May require grinding or painting for protection. | Typically needs passivation to enhance corrosion resistance. |

| Heat Affected Zone (HAZ) Properties | Lower hardness in the HAZ. | Higher hardness and potential for cracking in the HAZ. |

Why Is Steel Thickness Crucial When Selecting Sheets for Welding?

Steel thickness is crucial when selecting sheets for welding because it directly influences the integrity and strength of the welded joint, as well as the ease of the welding process.

According to the American Welding Society, thicker sheets provide better penetration during welding, which is essential for creating strong bonds between the metals. When welding thinner sheets, there is a higher risk of burn-through, where the heat from the welding process can create holes or weaken the material. This is particularly important in applications where structural integrity is critical, such as in construction or automotive manufacturing.

The underlying mechanism involves the heat distribution during the welding process. Thicker steel sheets can absorb and dissipate heat more effectively, allowing for a more controlled melting zone and reducing the likelihood of distortion. In contrast, thinner sheets heat up more quickly and can warp or deform under the intense heat of welding. Additionally, thicker materials often require different welding techniques and settings to accommodate their thermal properties, which can further complicate the welding process if not properly considered.

What Factors Should You Consider When Choosing Steel Sheets for Your Welding Station?

When choosing steel sheets for your welding station, several important factors must be considered to ensure optimal performance and safety.

- Material Type: The type of steel used significantly affects the welding process and final product quality. Common options include mild steel, stainless steel, and alloy steel, each offering unique properties such as strength, corrosion resistance, and ease of welding.

- Thickness: The thickness of the steel sheet can impact its strength and the type of welding techniques that can be employed. Thicker sheets generally require more heat and stronger welding techniques, while thinner sheets are easier to weld but may be more susceptible to warping.

- Surface Finish: The surface finish of the steel sheet can influence the quality of the weld. Smooth surfaces are preferable as they allow for better penetration of the weld, while rough or oxidized surfaces may require additional cleaning and preparation before welding.

- Size and Dimensions: Ensuring that the steel sheets fit the intended application is crucial. Consider the dimensions and weight of the sheets, as they should be manageable for your welding station setup, allowing for ease of handling and precise work.

- Weldability: Different steel grades have varying levels of weldability, which can affect the ease and quality of the weld. It is essential to choose sheets that are specifically designed for welding to ensure compatibility with your welding methods and materials.

- Cost: Budget considerations play a significant role in selecting steel sheets. While it may be tempting to opt for the cheapest option, balancing cost with quality and performance is essential to avoid additional expenses in repairs or replacements later on.

- Availability: The availability of specific types of steel sheets can vary by region and supplier. It is important to consider local suppliers and ensure that the materials you need can be readily sourced to avoid delays in your projects.

How Do Environmental Conditions Impact the Choice of Steel Sheets?

Environmental conditions significantly affect the choice of steel sheets for a welding station by influencing their performance and durability.

- Humidity: High humidity levels can lead to corrosion in steel sheets, particularly if they are not properly coated or treated. Choosing stainless steel or galvanized sheets can help mitigate this issue, ensuring longevity and reliability in a humid environment.

- Temperature: Extreme temperatures can affect the mechanical properties of steel, such as its ductility and strength. For welding stations in very hot or cold climates, selecting steel sheets that maintain their integrity under these conditions is crucial to prevent failures during welding.

- Exposure to Chemicals: Welding stations may be subject to various chemicals, including solvents and acids that can corrode standard steel sheets. Opting for sheets made from alloyed or treated steel that can withstand chemical exposure is vital for maintaining structural integrity over time.

- Air Quality: Airborne particulate matter and pollutants can accelerate the deterioration of steel sheets. In environments with poor air quality, using coated or treated steel that can resist rust and oxidation will help ensure the sheets remain functional and safe for welding applications.

- UV Exposure: Prolonged exposure to ultraviolet (UV) rays can degrade certain coatings on steel sheets, leading to rust and weakening of the material. It’s important to consider UV-resistant coatings or materials when setting up a welding station in outdoor or poorly shaded areas.

What Features Are Important for Durability in Steel Sheets?

Important features for durability in steel sheets include:

- Thickness: The thickness of steel sheets significantly impacts their strength and resistance to deformation. Thicker sheets can withstand greater forces and are less likely to warp or bend under high temperatures typically encountered in welding.

- Material Grade: The grade of steel determines its chemical composition and mechanical properties. High-grade steels, such as those classified under ASTM standards, offer enhanced durability, corrosion resistance, and improved weldability, making them ideal for welding stations.

- Surface Finish: A proper surface finish reduces the likelihood of corrosion and improves the adhesion of coatings. Steel sheets with smooth finishes can also facilitate easier cleaning and maintenance, which is essential in a welding environment where spatter and residues accumulate.

- Heat Treatment: Heat-treated steel sheets exhibit improved hardness and tensile strength. This process can enhance their resistance to thermal and mechanical stresses, making them more suitable for applications where high temperatures are prevalent.

- Corrosion Resistance: Steel sheets that are treated with protective coatings (such as galvanization) or made from stainless steel can resist rust and oxidation. This feature is crucial for maintaining the integrity of the sheets over time, especially in environments exposed to moisture or chemicals.

- Weldability: The ability of steel sheets to be easily welded without cracking or warping is critical for a welding station. Steel with good weldability ensures that the joints are strong and reliable, which is essential for the structural integrity of welded assemblies.

Who Are the Leading Manufacturers of Steel Sheets for Welding Stations?

The leading manufacturers of steel sheets for welding stations are known for their quality, reliability, and innovative solutions in the steel industry.

- Steel Dynamics, Inc.: This company is one of the largest domestic steel producers in the United States and offers a wide range of steel products, including sheets specifically designed for welding applications. They emphasize high-quality steel that meets rigorous industry standards, ensuring durability and performance in welding stations.

- ArcelorMittal: As a global leader in steel manufacturing, ArcelorMittal provides a variety of steel sheets that cater to different welding needs. Their products are renowned for their strength and versatility, making them suitable for various welding processes and environments.

- U.S. Steel: United States Steel Corporation is a major player in the steel industry, known for producing high-quality steel sheets used in welding stations. Their focus on innovation and sustainability allows them to offer products that not only perform well but also adhere to environmental standards.

- Thyssenkrupp AG: This multinational company is recognized for its advanced steel solutions, including sheets tailored for welding applications. Thyssenkrupp’s steel products are engineered for specific performance characteristics, providing users with reliable options for both structural and fabrication needs.

- POSCO: Based in South Korea, POSCO is one of the largest steel manufacturers in the world, known for its high-quality steel sheets suitable for welding. Their commitment to research and development allows them to produce steel that meets the demands of modern welding techniques while ensuring excellent weldability.

How Can You Ensure the Longevity of Steel Sheets in Your Welding Station?

To ensure the longevity of steel sheets in your welding station, consider the following factors:

- Material Quality: Using high-quality steel sheets is essential for durability and resistance to warping and corrosion.

- Thickness: The thickness of the steel sheet affects its strength and longevity; thicker sheets typically endure more stress and wear.

- Protective Coatings: Applying protective coatings can shield the steel from rust and other environmental factors that could degrade its quality.

- Proper Storage: Maintaining proper storage conditions reduces exposure to moisture and contaminants, which can lead to rust and deterioration.

- Regular Maintenance: Regular inspection and maintenance, including cleaning and addressing any signs of wear, can significantly extend the life of steel sheets.

Material Quality: High-quality steel sheets, such as those made from alloy or stainless steel, offer superior resistance to heat and corrosion. They are less likely to deform under the stress of welding and can withstand the rigors of a busy welding station.

Thickness: Thicker steel sheets provide greater strength and can handle more intense welding activities without bending or warping. Choosing the appropriate thickness based on the intended use ensures the sheets will not fail prematurely.

Protective Coatings: Applying coatings such as galvanization or powder coating helps protect steel sheets from rust and environmental damage. These coatings create a barrier that prevents moisture and contaminants from coming into direct contact with the steel surface.

Proper Storage: Storing steel sheets in a dry, clean environment helps prevent moisture accumulation and contamination from dirt or chemicals. Keeping the sheets elevated off the ground and covered can also protect them from environmental damage.

Regular Maintenance: Establishing a routine for inspecting and cleaning steel sheets can help identify potential issues early. Addressing minor problems, like surface rust, promptly can prevent them from developing into more significant issues that compromise the integrity of the sheets.

Related Post: