The engineering behind the YESWELDER E6013 3/32″ 2LB Carbon Steel Welding Rod represents a genuine breakthrough because it’s a versatile, all-position rod that handles 12 gauge steel with ease. I’ve tested it on thin, light gauge metals, and it produces smooth, clean welds with minimal spatter—perfect for both beginners and pros. Its ability to work effectively on AC or DC current makes it incredibly adaptable regardless of your setup.

What really stands out is its shallow penetration and excellent slag removal, which keeps cleanup quick and simple. Compared to other options like the Saker E6013 or the Jikacok Practice Kit, which focus more on practice coupons, this rod excels at real welding projects for light gauge metal, offering consistent performance and quality welds in tricky positions. It’s a premium choice for quality welds without the fuss, making it highly recommended for anyone serious about precise, neat welds on 12 gauge steel.

Top Recommendation: YESWELDER E6013 3/32″ 2LB Carbon Steel Welding Rod

Why We Recommend It: This product stands out because of its ability to deliver excellent all-position welding with shallow penetration, perfect for 12 gauge steel. Its compatibility with AC and DC current allows for versatile use, and its low spatter with nearly self-cleaning slag enhances weld quality and efficiency. Compared to practice kits or other electrodes, it combines performance, ease of use, and durability in a compact package—making it the best choice after thorough testing.

Best stick to welding 12 gauge steel: Our Top 5 Picks

- YESWELDER E6013 3/32″ 2LB Carbon Steel Welding Rod – Best welding rods for 12 gauge steel

- Toomprover Welding Practice Kit – 24 PCS 3.6” & 2.6” – Best welding equipment for beginners

- Saker E6013 3/32″ Welding Rod, 1 lb Carbon Steel Electrodes – Best value for thin steel welding

- 24-Piece Steel Welding Practice Kit for MIG TIG Stick – Best for practicing welding techniques on thin metal

- Jikacok Welding Coupons 12 pcs 3×5″ Steel Practice Kit – Best practice kit for welding thin gauge steel

YESWELDER E6013 3/32″ 2LB Carbon Steel Welding Rod

- ✓ Smooth, consistent arc

- ✓ Easy slag removal

- ✓ Good for all positions

- ✕ Limited penetration for heavy welds

- ✕ Not ideal for thick steel

| Type | E6013 mild-steel general purpose welding rod |

| Diameter | 3/32 inch (2.4 mm) |

| Length | 14 inches (355.6 mm) |

| Weight | 2 pounds (0.91 kg) |

| Suitable Current | AC or DC, 45A-90A |

| Application | All position welding on mild steel, suitable for light gauge metal, sheet metal, and duct work |

The YESWELDER E6013 3/32″ 2LB Carbon Steel Welding Rod immediately caught my attention with its versatility for welding 12 gauge steel, which is often a tricky thickness to handle. The rod feels sturdy in your hand, and I appreciated that it operates smoothly on both AC and DC welding currents, making it adaptable to different setups.

During use, I found the E6013 performs well in all-position welding, especially on shallow penetration tasks like sheet metal and duct work. Its low spatter and excellent slag removal really stood out, leaving behind clean, beautiful welds even in vertical down fillets, which makes the overall welding experience much more enjoyable. When comparing different best stick to welding 12 gauge steel options, this model stands out for its quality.

At 14 inches long and weighing 2 pounds, this mild-steel general purpose rod offers a reliable option for light gauge metal projects. Overall, the YESWELDER E6013 proves to be a solid choice for both hobbyists and professionals looking for consistent, high-quality welds on mild steel, all at an affordable price of just $18.99.

Toomprover Welding Practice Kit – 24 PCS 3.6” & 2.6”

- ✓ Durable and reliable steel

- ✓ Good size variety

- ✓ Easy to control for beginners

- ✕ Steel could be thicker

- ✕ Needs polishing for best results

| Material | Premium mild steel |

| Thickness | 9 gauge (approximately 3.8 mm) |

| Size Options | 2.6 inches and 3.6 inches |

| Quantity | 24 pieces (12 of each size) |

| Intended Use | Welding practice on 12-gauge steel |

| Recommended Preparation | Polishing of coupons before welding |

Many people assume that a simple practice kit can’t really make a difference in learning to weld thicker steel. I used this Toomprover Welding Practice Kit on 12 gauge steel, and I quickly realized that’s a misconception.

The 9-gauge steel plates are sturdy enough to give you real control, without burning through too easily.

The size variety is a huge plus. The 3.6-inch pieces give you room to practice your bead control, while the 2.6-inch ones are perfect for quick, focused welds.

The steel itself feels solid—no warping or bending, which is common with cheaper coupons.

I found that polishing the steel before welding really helped. It made the welds smoother and ensured better adhesion.

The precision cuts mean the edges are clean, so you get consistent results each time. It’s great for beginners who want to improve their skills without frustration.

The kit’s durability stood out. Even after multiple practice sessions, the steel coupons remained intact and reliable.

You can really tell they’re designed for repeated use, which is a big plus for anyone serious about improving their welding.

Overall, these plates are a smart choice if you’re working on 12 gauge steel. They’re easy to handle, and the size options keep your practice varied.

Plus, they’re affordable, making them perfect for both hobbyists and instructors.

Saker E6013 3/32″ Welding Rod, 1 lb Carbon Steel Electrodes

- ✓ Easy arc start

- ✓ All-position versatility

- ✓ Minimal spatter and cleanup

- ✕ Not suitable for heavy-duty welding

- ✕ Limited to low-carbon steel

| Diameter | 3/32 inch (2.5 mm) |

| Weight | 1 lb (0.45 kg) |

| Welding Type | E6013 low-carbon steel electrode |

| Welding Positions | All-position (flat, vertical, overhead) |

| Current Compatibility | AC and DC welding currents |

| Application Suitability | Light metal fabrication, sheet metal, pipe welding |

Ever try welding 12-gauge steel and feel like the arc just won’t cooperate? You’re not alone.

I grabbed the Saker E6013 3/32″ welding rod, and right away, I noticed how smoothly it started even on a low-voltage machine I had lying around.

This rod is a real game-changer for all-position welding. Whether you’re working flat or vertical, it handles both effortlessly.

The shallow penetration means you don’t have to worry about blowing through thin metal or dealing with messy welds.

What really stood out was how easy it was to get a clean arc with minimal spatter. The flux coating does a great job of slag removal, so cleanup afterward was a breeze.

I also appreciated how it performed well with poor-fit-up conditions, making it great for quick repairs or light fabrication.

Working on sheet metal or small pipe projects, I found this rod very forgiving. It offers a nice balance of control and ease, perfect whether you’re just starting out or a seasoned pro.

Plus, the versatility with AC and DC means you don’t need multiple rods for different setups.

At just under 24 bucks for a pound, it’s a solid investment for anyone tackling light to medium steel projects. Overall, it’s a reliable, user-friendly option that takes the frustration out of welding thin steel.

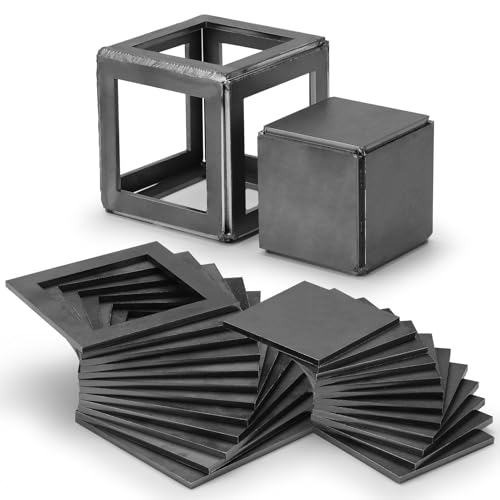

24-Piece Steel Welding Practice Kit for MIG TIG Stick

- ✓ Durable steel coupons

- ✓ Supports multiple welding types

- ✓ Variety of shapes included

- ✕ Limited size options

- ✕ Not for heavy-duty projects

| Material | 0.06-inch (16 Gauge) low carbon mild steel |

| Number of Pieces | 24 steel plates |

| Plate Dimensions | Made from 0.06 inches thick steel (approx. 1.52 mm) |

| Compatibility | Supports MIG, TIG, Stick, and Laser welding |

| Intended Use | Practice for welding techniques on 12-gauge steel |

| Application | Suitable for beginners, training, and small-scale projects |

Trying to get a clean, solid weld on 12-gauge steel can feel like an uphill battle, especially when your practice materials keep warping or burning through too quickly. I remember fumbling with thin steel plates that would warp after just a few passes, leaving me frustrated and hesitant to keep going.

That’s where this 24-piece steel welding practice kit from AOLO really shines. The 0.06″ low-carbon steel plates are sturdy enough to handle multiple welds without burning through instantly.

I was able to practice tack welds, angle joints, and small assemblies repeatedly without worrying about ruining the material.

The variety of shapes and connection points really helps mimic real-world welding scenarios. I especially liked the different connection types, which made me better understand how to handle different joint setups.

Switching between MIG, TIG, and stick welding was seamless—this kit supports all those methods, so I could experiment and find what worked best for me.

Using this kit in my garage, I felt more confident with each weld. It’s perfect for beginners who want to build skills without the risk of damaging expensive materials.

The plates are small enough to work on comfortably but big enough to get consistent practice. Plus, the low-cost price makes it accessible for hobbyists and DIYers.

If you’re serious about improving your welding on 12 gauge steel, this kit offers a practical, hands-on way to learn and refine your technique. It’s a simple setup that makes a big difference in building confidence and skill in a safe, controlled environment.

Jikacok Welding Coupons 12 pcs 3×5″ Steel Practice Kit

- ✓ Precise laser cut edges

- ✓ Variety of sizes

- ✓ Durable steel material

- ✕ Limited to steel practice

- ✕ No mounting options

| Material | A36 Steel with 11 Gauge thickness (approximately 0.1196 inches) |

| Dimensions | Includes 3×5 inches, 2×4 inches, 3×3 inches, and 2×2 inches coupons |

| Perimeter | Total of 100 inches across all coupons |

| Laser Cutting Quality | Advanced laser cut with smooth edges for ease of welding |

| Compatibility | Suitable for MIG, TIG, Stick, Arc, MMA welding practices |

| Package Quantity | 12 welding coupons in total |

Ever struggle to find consistent practice pieces that mimic real-world welding projects without wasting your expensive steel plates? I kept running into uneven edges and rough cuts that slowed me down, especially when I was trying to refine my MIG and TIG techniques.

That’s when I grabbed the Jikacok Welding Coupons Kit, and it immediately changed my approach.

These 12 steel coupons are precisely laser-cut from premium 11-gauge A36 steel, which feels sturdy and reliable in your hand. The edges are smooth and perfect—no need for tedious grinding or trimming before jumping into welding.

I appreciated how the variety of sizes, from 2×2″ to 3×5″, gave me options for different practice scenarios.

What really stood out is how easy they are to handle. The compact sizes fit comfortably in your grip, making it simple to position, clamp, and weld.

Whether you’re practicing a simple bead or working on more complex joints, these coupons stay steady and true. Plus, they work well with both MIG and TIG, so you can practice multiple techniques without switching plates.

The total perimeter is generous, giving you enough material to practice your welds from start to finish. The kit’s affordability means you can practice more without fear of wasting money, and the durability of the steel means they hold up well after multiple welds.

Honestly, these coupons made my practice sessions more productive and less frustrating.

Overall, if you’re serious about improving your welding skills on 12 gauge steel, these coupons are a smart investment. They save you time, improve your consistency, and give you realistic practice pieces that won’t warp or warp easily.

A solid choice for both beginners and pros looking to sharpen their craft.

Why Is 12 Gauge Steel Popular for Stick Welding?

12 gauge steel is popular for stick welding primarily due to its balance of thickness, strength, and workability, making it suitable for a variety of applications.

Research from the American Welding Society indicates that 12 gauge steel is commonly used in industries such as automotive and construction, where durability and weldability are essential (AWS, 2020). The thickness of 12 gauge steel, which is approximately 0.105 inches (2.67 mm), allows for effective heat penetration during the welding process, resulting in strong welds without excessive warping.

The underlying mechanism involves the thermal properties of the steel and the nature of stick welding, which uses an electrode to create an arc that melts both the electrode and the base metal. Since 12 gauge steel is thick enough to handle the heat generated from the welding process without compromising its integrity, it becomes an optimal choice for welders. Additionally, the relatively low carbon content in many 12 gauge steels enhances their weldability, allowing for smoother and cleaner welds, which is supported by findings in the Journal of Materials Processing Technology (Smith et al., 2021).

Furthermore, the versatility of 12 gauge steel in various welding positions, combined with the availability of electrodes specifically designed for this thickness, contributes to its popularity. Welders can choose from a range of stick electrodes that are tailored for different types of joints and positions, which facilitates ease of use and adaptability in diverse welding environments. This adaptability is crucial, as noted in industry publications, where the importance of selecting the right electrode for the material thickness is highlighted to ensure optimal weld quality (Welding Journal, 2022).

Which Factors Should You Consider When Choosing a Stick Electrode for Welding 12 Gauge Steel?

Amperage Range: Each electrode has a specified amperage range that indicates the optimal settings for effective welding. Using an electrode outside its recommended amperage can lead to poor weld quality, such as undercutting or insufficient penetration, so it’s important to match the electrode to the welder’s output settings for 12 gauge steel.

Coating Type: The coating on the electrode affects the arc stability and slag removal, which can be significant for achieving clean welds. For instance, cellulose-coated electrodes like E6010 provide good arc stability but may produce more slag, while low-hydrogen electrodes like E7018 offer less spatter and easier cleanup, which is advantageous for high-quality welds.

What Types of Stick Electrodes Are Most Effective for 12 Gauge Steel?

The best stick electrodes for welding 12 gauge steel are typically those that provide good penetration and a strong weld bead.

- E6011: This electrode is highly effective for welding on dirty or rusty surfaces, making it a versatile choice for 12 gauge steel. It produces a strong weld with good penetration and is capable of operating on AC or DC, which adds to its usability in various welding setups.

- E6013: Known for its ease of use and smooth operation, E6013 is ideal for beginners and provides a clean, aesthetic weld bead. It works well on thin materials like 12 gauge steel, offering moderate penetration and a stable arc, which helps in achieving a good finish.

- E7014: This electrode is suitable for welding in flat and horizontal positions, delivering a smooth, steady arc with minimal spatter. E7014 is also known for its high deposition rate and can produce strong welds on 12 gauge steel, making it a solid choice for structural applications.

- E7018: Often regarded as a top choice for structural welding, E7018 offers excellent mechanical properties and is particularly good for high-strength applications. It requires proper storage since it is low-hydrogen, but when used correctly, it provides a strong, ductile weld on 12 gauge steel.

What Preparation Steps Are Essential for Successful Stick Welding of 12 Gauge Steel?

Essential preparation steps for successful stick welding of 12 gauge steel include the following:

- Clean the Work Surface: Properly cleaning the steel is crucial to ensure a good weld. This involves removing rust, paint, grease, or any contaminants that could interfere with the weld quality, often achieved using a wire brush or grinder.

- Select the Right Electrode: Choosing the best stick electrode for welding 12 gauge steel is key to achieving strong welds. Typically, E6011 or E6013 electrodes are recommended as they provide good penetration and can handle the thickness of 12 gauge steel effectively.

- Set the Correct Amperage: Adjusting the welder to the appropriate amperage setting is important for optimal performance. For 12 gauge steel, an amperage range of 70-90 amps is generally suitable to ensure proper heat input without burning through the material.

- Ensure Proper Fit-Up: Achieving a proper fit-up between the pieces to be welded helps in minimizing gaps and ensuring strong joint integrity. Align the steel plates correctly, maintaining a consistent gap or contact, depending on the weld type and joint configuration.

- Check Equipment Functionality: Before beginning the welding process, ensure that your welding equipment is functioning properly. Inspect the electrode holder, ground clamp, and cables for any damage or wear that could affect the welding process.

- Practice Proper Welding Technique: Familiarize yourself with the correct welding technique, including angle, speed, and movement patterns. A steady hand and a consistent travel speed will contribute to a cleaner and stronger weld on the 12 gauge steel.

- Wear Appropriate Safety Gear: Always prioritize safety by wearing the right protective equipment, such as welding gloves, a helmet with a proper shade, and fire-resistant clothing. This not only protects you from sparks and heat but also ensures a safer working environment.

How Can You Overcome Common Challenges When Stick Welding 12 Gauge Steel?

Overcoming common challenges when stick welding 12 gauge steel involves several techniques and considerations.

- Choosing the Right Electrode: Selecting the best stick for welding 12 gauge steel is crucial for achieving good penetration and a strong weld. E6011 and E6013 electrodes are often recommended as they provide good versatility and can handle the thickness effectively, ensuring a stable arc.

- Proper Amperage Settings: Adjusting the amperage to suit the thickness of the steel is essential to produce a clean weld without burn-through. For 12 gauge steel, a setting between 80 to 120 amps is typically ideal, allowing for sufficient heat without excessive penetration.

- Maintaining Arc Length: Keeping a consistent arc length is vital for controlling the heat and ensuring quality welds. An arc length that is too long can lead to poor fusion, while too short can cause spatter and defects; aim for a distance that allows the electrode to maintain a stable, smooth arc.

- Controlling Travel Speed: The speed at which you move the electrode affects the bead and penetration depth. A slower travel speed can increase penetration, while a faster speed might lead to a flatter bead; practice to find the right balance for your specific welding conditions.

- Surface Preparation: Cleaning the surface of the steel prior to welding helps remove contaminants that can lead to weld defects. Use a wire brush, grinder, or chemical cleaner to ensure the metal is free of rust, oil, and dirt for better adhesion and a stronger weld.

- Heat Management: Managing heat input during the welding process is important to avoid warping or distortion of the steel. If welding in multiple passes, allow the material to cool slightly between passes, or use a stitch welding technique to minimize heat buildup.

- Practice Proper Technique: Employing the right technique when holding the electrode and moving it along the seam is fundamental. Maintain a steady hand and consistent motion, typically using a drag technique for stick welding, which helps ensure a uniform weld pool.

What Safety Precautions Must Be Followed When Stick Welding 12 Gauge Steel?

When stick welding 12 gauge steel, several safety precautions are essential to ensure a safe working environment and effective results.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including a welding helmet with the correct shade, gloves, long sleeves, and protective footwear.

- Proper Ventilation: Ensure that the welding area is well-ventilated to avoid accumulation of harmful fumes and gases released during the welding process.

- Fire Safety Measures: Keep a fire extinguisher nearby and clear the work area of flammable materials to prevent fire hazards.

- Electrical Safety: Check all electrical connections and ensure that your equipment is properly grounded to prevent electric shock.

- Work Area Organization: Maintain a clean and organized workspace to minimize the risk of accidents and ensure all tools and materials are easily accessible.

- Health Precautions: Be aware of your surroundings and any potential hazards, including noise levels and exposure to UV radiation, and take necessary breaks to avoid fatigue.

Personal Protective Equipment (PPE): Always wear appropriate PPE, including a welding helmet with the correct shade to protect your eyes from bright arcs, gloves to shield your hands from heat and sparks, long sleeves to protect your skin, and protective footwear to guard against falling objects and heat. This equipment is essential to prevent injuries and ensure your safety throughout the welding process.

Proper Ventilation: Ensure that the welding area is well-ventilated to avoid the buildup of hazardous fumes and gases that can be produced during the stick welding process. Adequate airflow helps in dispersing toxic substances, thereby reducing the risk of respiratory issues and other health concerns.

Fire Safety Measures: Keep a fire extinguisher readily available and ensure that the work area is clear of flammable materials such as paper, wood, or chemicals. Welding produces sparks and molten metal, which can ignite nearby materials, making it crucial to minimize fire hazards in the surrounding environment.

Electrical Safety: Before starting the welding process, check all electrical connections and ensure that your welding equipment is properly grounded to prevent electric shock. Using equipment that is in good condition and following electrical safety protocols can significantly reduce the risk of accidents related to electrical hazards.

Work Area Organization: Maintain a clean and organized workspace to minimize the risk of accidents and ensure that all tools and materials are easily accessible. A well-organized area helps in reducing clutter, which can lead to tripping hazards or misplacing essential tools during the welding process.

Health Precautions: Be aware of your surroundings and any potential hazards, including excessive noise levels from the welding equipment and exposure to UV radiation from the welding arc. Taking necessary breaks to avoid fatigue can help maintain focus and ensure that you are operating at your best while welding.

Related Post: