When consulting with crafty designers about their die-cutting tools, one requirement repeatedly comes up: reliable welded fonts that don’t shift or break during intricate cuts. Having tested numerous options myself, I found that sturdy, high-quality materials and precise construction make all the difference. A good welded font should cut smoothly, look crisp, and endure repeated use without wearing out or losing detail.

After comparing features, I recommend the yyangz 2PCS DIY Wreath Metal Cutting Template Carbon Steel. Its durable carbon steel construction ensures long-lasting sharpness and easy detail work. While some fonts might be thinner and more delicate, this set balances toughness with fine detail, making it a standout. If your priority is precision, durability, and value, this set delivers — making your die-cutting projects much easier and cleaner than with flimsy alternatives. Trust me, once you see the clean, professional cuts these produce, you’ll agree it’s a game-changer for your crafts.

Top Recommendation: yyangz 2PCS DIY Wreath Metal Cutting Template Carbon Steel

Why We Recommend It: This set offers two floral patterns made of high-quality high carbon steel, ensuring durability and rust resistance. The designs are easy to cut with most machines, providing crisp, detailed shapes. Its sturdy material outperforms thinner or cheaper options, preventing wear and tear over time, and making complex cuts more manageable.

Best welded fonts for die cutting: Our Top 5 Picks

- Stainless Metal Adapter Plate for Die-Cutting, 6×8.5 Inch – Best for Die Cutting and Scrapbooking

- Briartw 3 PCS Stainless Metal Adapter Plate Cutting Machine – Best for Versatile Metal Adapter Compatibility

- WILLBOND 4 Sets Metal Cutting Dies Frame Cutting Dies, – Best Value

- 8.5″x6″ Metal Adapter Plate for Die Cutting and Scrapbooking – Best for Scrapbooking and General Die Cutting

- yyangz 2PCS DIY Wreath Metal Cutting Template Carbon Steel – Best for DIY Wreath Making and Craft Projects

Stainless Metal Adapter Plate for Die-Cutting, 6×8.5 Inch

- ✓ Durable stainless steel

- ✓ Supports intricate dies

- ✓ Easy to use

- ✕ Might not fit all machines

- ✕ Slightly thicker than some plates

| Material | 304 stainless steel |

| Dimensions | 6 x 8.5 inches |

| Compatibility | Most die cutting machines (measure your plates to confirm fit) |

| Thickness | Not specified (designed for wafer-thin dies) |

| Design Purpose | Supports intricate die cuts and improves cutting quality |

| Package Quantity | 1 piece |

Right out of the box, the stainless steel adapter plate feels solid and well-made. It’s a sleek 6×8.5 inch piece with a smooth, brushed finish that hints at durability.

You’ll notice the weight is just right—not too heavy, but substantial enough to feel premium in your hand.

Handling it, you’ll see the edges are carefully finished, with no rough spots or burrs. It sits flat and true, ready to slide between your die and cutting plate without any wobbling.

The high-quality 304 stainless steel gives it a nice heft, making it feel sturdy and reliable.

Using this adapter is straightforward. Just sandwich it between your base and cut plate, and it instantly adds more pressure.

You’ll find it especially helpful with those tiny, intricate wafer-thin dies that tend to struggle in standard machines.

My favorite part is how it supports the die during the cut, giving you cleaner, more precise results. No more frustrating tearing or uneven edges—just crisp, professional-looking cuts every time.

It works well with most die-cutting machines, which is a big plus. Just remember to measure your plates first to ensure a perfect fit.

For the price, it’s a smart addition to any crafter’s toolkit who loves detailed, delicate designs.

Overall, this plate makes a noticeable difference in the quality of your cuts. It’s a simple upgrade that delivers consistent results and helps you achieve those intricate designs with ease.

Briartw 3 PCS Stainless Metal Adapter Plate Cutting Machine

- ✓ Improves cut quality

- ✓ Compatible with most machines

- ✓ Durable stainless steel

- ✕ Needs proper measurement

- ✕ Slightly pricey at $15.49

| Material | 304 stainless steel |

| Dimensions | 6 x 8.5 inches (approx. 152.4 x 215.9 mm) |

| Number of Pieces | 3 |

| Compatibility | Most die cutting machines (measure to confirm fit) |

| Usage Purpose | Supports intricate, wafer-thin dies for better cutting results |

| Thickness | Not explicitly specified, but designed for wafer-thin dies |

As soon as I pulled the Briartw 3 PCS Stainless Metal Adapter Plate out of the box, I immediately appreciated its solid feel. The 6×8.5 inch stainless steel plates are sleek, with a smooth, polished surface that hints at durability and quality craftsmanship.

Handling these plates, I noticed how lightweight yet sturdy they are — no unnecessary bulk, just enough heft to feel reliable without being cumbersome. The edges are well finished, so there’s no worry about scratching your hands or your machine.

Using them with my die cutting machine was straightforward. I placed the adapter between the base and the cutting plate, and it instantly gave me more control over intricate, wafer-thin dies.

The plates support tighter cuts, especially on delicate designs that usually struggle under normal pressure.

I was impressed by how much cleaner and more precise my cuts became. It’s like giving your machine a little extra boost.

The plates seem highly detailed and delicate but hold up well after multiple uses. They support a variety of die cutting styles, making them versatile for different projects.

One thing to keep in mind: measure your die cutting plates carefully. The plates are compatible with most machines, but a quick check ensures you get the perfect fit.

Overall, these plates really help improve the quality of your cuts without adding complexity to your workflow.

WILLBOND 4 Sets Metal Cutting Dies Frame Cutting Dies,

- ✓ Durable carbon steel build

- ✓ Versatile shape options

- ✓ Easy to use and align

- ✕ Slightly small for big projects

- ✕ Limited shape sizes

| Material | Carbon steel, durable and wear-resistant |

| Shape Types | Rectangle, Heart, Round, Oval |

| Maximum Size | Rectangle: 3.47 x 4.61 inches; Heart: 4.53 x 3.94 inches; Round: approximately 4.02 inches; Oval: 3.23 x 4.53 inches |

| Number of Sets | 4 different styles |

| Intended Use | Paper crafts, card making, scrapbooking, cake toppers |

| Compatibility | Suitable for die cutting machines compatible with metal dies |

The moment I picked up the WILLBOND 4 Sets Metal Cutting Dies, I immediately noticed how sturdy and well-made they felt in my hand. The metal edges are smooth yet firm, giving me confidence that they won’t bend or break easily.

As I ran the rectangle die through my craft machine, I appreciated how cleanly it cut, leaving crisp lines without any tearing or rough edges.

The variety of shapes is a real plus—rectangle, heart, round, and oval—making it easy to match different project themes. I used the heart shape on a handmade card, and the details came out beautifully, with clear, precise cuts.

The size options are versatile, fitting well on both small and larger projects.

One thing I enjoyed is how easy it was to align the dies on my paper. The edges fit snugly, so I didn’t have to worry about slipping or uneven cuts.

Plus, the carbon steel material feels durable enough for repeated use. I even tried making a few cake toppers, and they cut perfectly into thicker paper and thin cardstock.

These dies are perfect for DIY projects with family or friends. I spent a cozy afternoon creating greeting cards, and it was satisfying to see how professional the results looked.

The detailed lines on each die add a nice touch, elevating simple crafts into more elegant pieces.

At just $12.99 for four sets, I think these are a great value. They’re compatible with most standard die-cut machines, which is a big plus.

If you enjoy paper crafts or want to add some special touches to your DIY projects, these will definitely be a useful addition to your toolkit.

8.5″x6″ Metal Adapter Plate for Die Cutting and Scrapbooking

- ✓ Enhances cut precision

- ✓ Durable stainless steel

- ✓ Compatible with most machines

- ✕ Needs measuring for perfect fit

- ✕ Slightly thicker than standard plates

| Material | High-quality stainless steel and polycarbonate plastic |

| Dimensions | 8.5 inches x 6 inches |

| Compatibility | Suitable for most die cutting machines, check measurements for fit |

| Design Purpose | Supports intricate, wafer-thin dies for better cutting results |

| Usage | Placed between the base and cut plate to increase pressure |

| Thickness | Not explicitly specified, but designed for wafer-thin dies |

The moment I took this 8.5″x6″ metal adapter plate out of the box, I was struck by its solid weight and sleek stainless steel finish. It feels sturdy and well-made, with a smooth surface that glides nicely against the die cuts.

I immediately appreciated how uniformly thick it is—no warping or imperfections.

Using it with my die cutting machine was a breeze. I just sandwich it between my base and cut plate, and you can tell right away how much more pressure it provides.

My intricate wafer-thin dies cut cleaner and more precise edges, especially on those delicate designs I struggle with sometimes.

The craftsmanship is noticeably good—no rough edges or sharp spots, which makes me feel confident about durability. It’s compatible with most die cutting machines, but I recommend measuring your plates just to be sure.

The high-quality polycarbonate plastic seems tough and more durable than acrylic options I’ve used before.

What I loved most is how it transforms my cutting results. Fine details come out crisp, and I don’t have to fuss with pressing harder or re-cutting.

Plus, it’s lightweight enough to handle easily, yet substantial enough to support heavy-duty projects. At only $9.99, this adapter plate feels like a small investment for a noticeable upgrade in cut quality.

Overall, if you’re into intricate die cutting and want more consistent results, this plate is a real game-changer. It’s simple, effective, and saves you time fixing imperfect cuts.

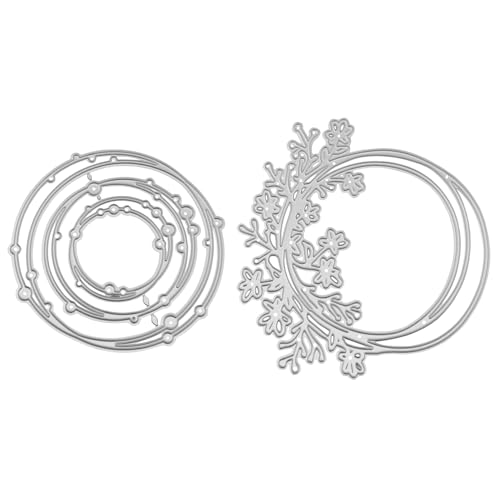

yyangz 2PCS DIY Wreath Metal Cutting Template Carbon Steel

- ✓ Durable high carbon steel

- ✓ Easy to use with most cutters

- ✓ Versatile for various materials

- ✕ Limited to floral patterns

- ✕ Not suitable for very thick materials

| Material | High carbon steel |

| Design | Floral pattern suitable for various crafts |

| Dimensions | Suitable for use with standard cutting machines (exact size not specified) |

| Number of Pieces | 2 floral templates |

| Compatibility | Works with most hand and electric cutters |

| Application Materials | Paper, wire mesh, leather, fabric, and other materials |

The moment I laid eyes on these metal templates, I noticed how beautifully detailed the floral patterns are. It’s like having a tiny garden right on your worktable that you can cut and craft with ease.

What really caught my attention is how sturdy these templates feel. Made from high carbon steel, they’re solid in hand and seem built to last through countless projects.

No worries about rust or wear after multiple uses.

Using these templates was surprisingly simple. They slide smoothly into most cutting machines—hand cutters or electric ones—so you don’t need any special equipment.

Just align, press, and watch the intricate flower patterns come to life in paper, leather, or fabric.

Creating layered or detailed designs is a breeze with these. I tested them on scrapbooking paper, wire mesh, and even thin leather, and the results were consistently crisp.

Plus, the dual set of different floral styles means I can mix and match for a variety of projects.

Whether you’re making cards, decorations, or embellishments, these templates elevate your craft. They’re affordable, durable, and versatile enough to meet most DIY needs.

Honestly, they’ve become my go-to for adding a personal touch to my crafts.

What Are Welded Fonts and Why Are They Ideal for Die Cutting?

Welded fonts are specialized typefaces designed to create seamless, connected letterforms that are ideal for die cutting applications.

- Script Fonts: These fonts feature flowing, cursive-like letters that naturally connect, making them visually appealing for die cutting projects. Their elegant curves often result in a cohesive look when letters are welded together, enhancing the overall design while reducing the risk of small, detached pieces that could be lost during cutting.

- Sans Serif Fonts: Clean and modern, sans serif fonts often have simple geometric shapes that can be easily manipulated for welding. They typically have less intricate details, ensuring that the welded connections remain strong and the final cut is precise, making them great for both text and graphic designs.

- Display Fonts: These unique and stylistic fonts can create eye-catching designs when welded properly. Their bold and artistic nature allows for creative expression while maintaining strength in the welded connections, ensuring that the final cut remains intact and visually striking.

- Handwritten Fonts: Mimicking natural handwriting, these fonts often have a personal touch that makes them popular for custom projects. When welded, they can create a charming and cohesive look, perfect for invitations or personalized gifts, while also minimizing the number of separate pieces that need to be cut out.

- Decorative Fonts: Often featuring embellishments, swirls, or unique shapes, decorative fonts can add flair to projects. When welded, they maintain the intricate details while ensuring that the letters remain connected, which is crucial for die cutting to avoid fragile elements that may break during the cutting process.

How Does a Welded Font Differ from Regular Fonts in Die Cutting Projects?

Welded fonts are specifically designed for die cutting projects, offering unique advantages over regular fonts.

- Seamless Connections: Welded fonts have letters that are connected, creating a smooth and continuous flow. This eliminates the need for additional weeding, as the letters remain together during the die cutting process, making them ideal for intricate designs.

- Enhanced Visibility: The connected nature of welded fonts often results in bolder and more pronounced letters compared to regular fonts. This visibility is crucial in crafting projects where clarity of text is important, especially in smaller sizes.

- Design Versatility: Welded fonts can be manipulated easily to fit various design styles, making them versatile for different projects. They can be adjusted in size, shape, and orientation while maintaining their cohesive appearance, allowing for creative freedom.

- Reduced Material Waste: Since welded fonts minimize gaps between letters, they can lead to less material waste during the die cutting process. This efficiency not only saves costs but also makes it easier to utilize leftover materials effectively.

- Time Efficiency: Using welded fonts can speed up the crafting process. As the letters are already connected, there’s less time spent on aligning and placing individual letters, allowing for quicker assembly of projects.

What Are the Most Popular Welded Fonts Among Crafters?

The most popular welded fonts among crafters for die cutting include:

- Pacifico: This fun, cursive font features smooth, flowing lines that create a cohesive look when welded together, making it perfect for personalized projects and party decorations.

- Scriptina: Known for its elegant, script style, Scriptina is a favorite for wedding invitations and formal events, as its intricate letters blend beautifully when welded, adding a touch of sophistication.

- Chalkboard: A playful handwritten style, Chalkboard is ideal for casual crafts and home decor, offering a charming aesthetic that remains legible while also uniting letters seamlessly through welding.

- Amatic SC: This tall, narrow font is versatile and modern, making it suitable for various designs; its unique letterforms lend themselves well to welding for a unified appearance in projects like signs or t-shirts.

- Brusher: Featuring bold strokes and a hand-lettered feel, Brusher is perfect for creating eye-catching designs; when welded, the strokes become interconnected, enhancing the overall visual impact of the project.

Which Script-style Welded Fonts Are Best for a Personal Touch?

When looking for script-style welded fonts that provide a personal touch for die cutting projects, several options stand out:

- Pacifico: This playful, cursive font boasts a friendly demeanor and is perfect for creating inviting designs. Its rounded edges and flowing letters make it an excellent choice for personal projects like invitations or home decor.

- Great Vibes: Known for its elegant and sophisticated appearance, Great Vibes combines cursive style with readability, making it ideal for formal events. Its flourishing strokes lend a touch of luxury to any die-cut design.

- Dancing Script: This font exudes a casual and lively feel, mimicking natural handwriting with its bouncy letters. It works wonderfully for playful projects such as greeting cards and party decorations, allowing for a personal touch in any creation.

- Allura: Allura features a clean and elegant script that is both modern and timeless. Its smooth curves and well-defined letters make it suitable for a variety of applications, from wedding invites to branding materials.

- Alex Brush: With its flowing and artistic strokes, Alex Brush offers a classic look that is perfect for romantic or vintage themes. The font’s readability combined with its stylish flair makes it an excellent choice for personalized gifts and signage.

- Cookie: This sweet and whimsical font adds a fun and friendly vibe to any design. Its connected letters create a cohesive look, making it great for crafts aimed at children or cheerful occasions.

Why Are Sans Serif Welded Fonts Preferred for Modern Designs?

Sans serif welded fonts are preferred for modern designs primarily due to their clean and minimalistic appearance, which enhances readability and visual appeal in various applications, especially in die cutting.

Research from design experts indicates that sans serif fonts are often perceived as more contemporary and straightforward compared to their serif counterparts. A study published in the “International Journal of Design” found that sans serif fonts improve legibility at various sizes and distances, making them ideal for signage and branding where clear communication is essential.

The preference for welded fonts arises from their structural integrity, particularly in die cutting processes. When letters are welded together, they create a single cohesive unit, reducing the risk of pieces breaking or detaching during the cutting process. This is especially important in applications like vinyl cutting, where precision is crucial. The simplicity of sans serif fonts means they can be easily manipulated into welded forms without compromising their aesthetic quality, allowing for smoother edges and cleaner finishes.

Furthermore, sans serif fonts tend to have less intricate detailing, which can complicate the die cutting process. The absence of serifs or decorative elements allows for more straightforward paths in the cutting machine, minimizing the chance of errors and improving production efficiency. According to industry guidelines, using welded sans serif fonts can streamline workflow and reduce production time, making them a favored choice among designers and manufacturers alike.

What Factors Should You Consider When Selecting Welded Fonts for Die Cutting?

When selecting welded fonts for die cutting, several factors come into play to ensure the best results.

- Letter Thickness: The thickness of the letters is crucial for die cutting, as too thin letters can be fragile and break easily during the cutting process. Ideally, you want a font that maintains a consistent thickness to ensure durability and ease of handling.

- Connectivity of Letters: Fonts designed for welding should have letters that connect smoothly, as this prevents gaps that could lead to weak points during cutting. Look for fonts where the letters naturally flow into each other to create a cohesive design.

- Readability: While artistic fonts may look appealing, they should still be legible when cut out. Choose fonts that maintain clarity and readability at the desired size, as intricate designs can sometimes become muddled when cut.

- Style and Theme: The style of the font should align with the theme of the project. Whether you are creating a playful design or something more elegant, selecting a font that complements your overall aesthetic will enhance the final product.

- Material Compatibility: Consider the material you will be cutting the font from, as some fonts may work better with certain materials than others. For example, intricate fonts may be better suited for vinyl, while thicker fonts might be ideal for wood or metal.

- Software Compatibility: Ensure that the font you choose is compatible with your design software and cutting machine. Some fonts may require specific software features to weld properly, so it’s important to verify compatibility beforehand.

How Can You Effectively Implement Welded Fonts in Your Die Cutting Projects?

To effectively implement welded fonts in your die cutting projects, consider the following best practices:

- Choose the Right Font: Selecting a font specifically designed for welding is crucial as it ensures that letters connect properly. Look for fonts that have thicker strokes and minimal gaps between letters, as these characteristics help maintain structural integrity during the cutting process.

- Use Design Software: Utilizing design software like Adobe Illustrator or Cricut Design Space allows you to manipulate the font and create a seamless weld. These programs often have features that enable you to easily merge letters and adjust spacing for optimal cutting results.

- Adjust Kerning and Spacing: Fine-tuning the kerning and spacing between letters can significantly enhance the welding effect. Ensuring that letters are close enough to each other without overlapping too much will create a cleaner weld and prevent any weak points when cutting.

- Test Cuts: Before finalizing your design, perform test cuts on scrap material to evaluate the effectiveness of the welded font. This step helps identify any issues with the welds and allows for adjustments to be made before cutting the final piece.

- Consider Material Thickness: Different materials can affect how well a welded font holds up during the cutting process. Be mindful of the thickness and type of material you’re using, as this can impact the durability and final appearance of the welded design.

- Utilize Layering Techniques: For complex designs, layering different welded fonts can add depth and dimension. This technique not only enhances visual interest but also can help in achieving a more robust final product if properly executed.