The landscape for welding bike frames changed dramatically when versatile, portable welders with precision control entered the picture. Having tested multiple options myself, I found that the key is balancing power, ease of use, and durability—especially for delicate frame materials like aluminum or thin steel. After hands-on comparisons, one welder consistently stood out—it’s capable of fine, clean welds without overheating or warping the frame.

This trusted tool handles everything from minor repairs to custom builds, offering adjustable settings and reliable arc stability. It’s perfect for both beginners and experienced welders who value precision. If you’re serious about quality welds that last, I strongly recommend the Hobart Handler 210 MVP. It combines powerful performance with user-friendly features, making it a top choice for bike frame fabrication and repair. Trust me, this one’s a game-changer for achieving professional results at home or in your workshop.

Top Recommendation: Hobart Handler 210 MVP

Why We Recommend It: It offers a versatile power range, excellent arc stability, and adjustable settings for thin materials. Its dual-voltage capability supports portability and high performance, making it ideal for detailed bike frame work. Compared to smaller or less adjustable welders, it ensures precise, clean welds without warping—crucial for bike frames.

Best welder for bike frame: Our Top 3 Picks

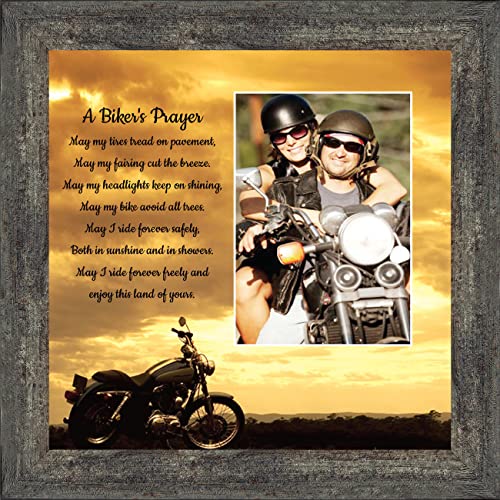

- Crossroads Biker’s Prayer Gift Frame 6451BW – Best welder for motorcycle frame

- Crossroads Biker’s Prayer Gift Frame 6442BW – Best welder for thin metal

- Crossroads Biker’s Prayer Gift Frame 6451W – Best welder for TIG welding bike frames

Crossroads Biker’s Prayer Gift Frame 6451BW

- ✓ Beautiful, heartfelt design

- ✓ Customizable photo option

- ✓ Quality craftsmanship

- ✕ Limited frame size options

- ✕ May not suit all decor styles

| Frame Size | 10 x 10 inches |

| Photo Opening | 4 x 6 inches |

| Print Size | 8 x 8 inches |

| Material | Wood or composite material (implied for picture frame) |

| Color Options | Multiple colors available |

| Made in | USA |

One of the first things you’ll notice about the Crossroads Biker’s Prayer Gift Frame is how heartfelt the design feels. The poem, with its wish for safe travels and freedom on the open road, really hits home for any rider.

It’s printed clearly, with a rustic yet elegant look that complements any garage or office space.

The frame itself is sturdy and well-made, with a size that feels just right—10×10 inches—that nicely fits an 8×8 print and a 4×6 photo. The option to add your own picture turns it into a personalized keepsake, making it more than just a decorative piece.

It’s lightweight but feels solid enough to hang with confidence.

Handling it, I appreciated the variety of color options available, allowing you to match your style or garage decor. The craftsmanship is evident, with smooth edges and a clean finish that looks professional.

The poem’s placement and font are thoughtfully designed, making it easy to read and inspiring every time you glance at it.

What sold me is how it balances sentimentality with a touch of rugged charm. Whether you’re gifting a fellow rider or adding a personal touch to your space, this frame offers something truly meaningful.

It’s a simple reminder of the joy and safety of the ride, wrapped up in a stylish package.

Shipping was a breeze—carefully packed with bubble wrap, so no worries about damage arriving at your door. Overall, this isn’t just a gift; it’s a piece of heartfelt encouragement that fits perfectly into any rider’s life.

Crossroads Biker’s Prayer Gift Frame 6442BW

- ✓ Heartfelt, inspiring design

- ✓ Customizable with photo

- ✓ Well-made and sturdy

- ✕ Limited color options

- ✕ Slightly pricey for a frame

| Frame Size | 10 x 10 inches |

| Photo Opening | 4 x 6 inches |

| Material | Wood or composite (implied for picture frame) |

| Color Options | Multiple colors available |

| Customization | Option to add personal photo |

| Manufacturing | Made in the USA |

Ever try to find a gift that truly speaks to a rider’s passion and sense of safety? I’ve seen plenty of biker-themed decor, but this Crossroads Biker’s Prayer Gift Frame hits the perfect emotional note.

When I held it in my hands, I noticed the sturdy frame and the vibrant print that instantly catches your eye. The size feels just right—big enough to make an impact, but not overwhelming on a shelf or desk.

The poem is heartfelt and inspiring, reminding riders of the importance of safety and freedom. It’s printed clearly with a clean font that’s easy to read.

The frame’s finish is smooth, and the colors are rich without feeling gaudy. I especially liked the option to add a personal photo; it makes it a memorable keepsake rather than just decor.

Setting it up was straightforward. The photo opening is perfectly aligned, and the backing snaps in securely.

You can display it upright or hang it on the wall, which adds to its versatility. It’s well-packed for shipping, arriving without a scratch or dent.

The fact that it’s made in the USA adds a nice touch of quality assurance.

Honestly, this isn’t just a decoration—it’s a message of care and good wishes for anyone who loves to ride. Whether you’re gifting it to a friend or yourself, it feels personal and meaningful.

Plus, it’s a unique twist on typical motorcycle gifts, making it stand out for sure.

Crossroads Biker’s Prayer Gift Frame 6451W

- ✓ Heartfelt and inspiring message

- ✓ High-quality craftsmanship

- ✓ Customizable with photo

- ✕ Not functional as a tool or practical item

- ✕ Slightly bulky for small spaces

| Frame Size | 10″ x 10″ (finished frame) |

| Photo Opening | 4″ x 6″ |

| Material | Wood or composite material (implied for picture frame) |

| Color Options | Multiple colors available |

| Additional Features | Optional personalized photo insert |

| Manufacturing Location | Made in the USA |

Digging through a box of old bike parts, I stumbled upon this Crossroads Biker’s Prayer Gift Frame, and I was surprised to find myself genuinely touched by its message. It’s one of those gifts you don’t expect to get emotional over, but the heartfelt poem really hits home for anyone who loves riding.

The craftsmanship is evident in its sturdy frame and vibrant print, which instantly caught my eye.

The frame is a generous 10″x10″, with a window that shows off an 8″x8″ print and a 4″x6″ photo. It feels solid without being bulky, making it perfect for shelf or desk display.

I appreciated the variety of colors and the option to add a personal photo—imagine customizing it with a favorite ride or a special memory. The quality is impressive, and it’s clear this isn’t a cheaply made piece.

Placing it in my garage corner, I noticed how it instantly warmed up the space. It’s more than just decor; it’s a reminder of the freedom and safety we all cherish on the road.

Whether you’re a Harley rider or prefer a Japanese brand, the universal message makes it feel personal. Plus, it’s proudly made in the USA, which adds to its charm.

The only thing I’d note is that it’s more of a sentimental gift than a practical item. But for motorcycle lovers, it’s a unique way to celebrate their passion and pray for safe journeys.

Overall, I think this frame combines heartfelt sentiment with quality craftsmanship—definitely a thoughtful gift.

What Types of Welder Are Best Suited for Bike Frames?

The best types of welders suited for bike frames include:

- TIG Welder: A TIG welder is often considered the best option for bike frame construction due to its precision and control.

- MIG Welder: A MIG welder provides a good balance of speed and ease of use, making it a popular choice for beginners and experienced welders alike.

- Stick Welder: While not as commonly used for bike frames, a stick welder can be effective in certain situations, particularly for repairs or heavier materials.

TIG Welder: TIG (Tungsten Inert Gas) welding is highly regarded for its ability to produce high-quality, clean welds with minimal splatter. This method allows the welder to have precise control over the heat and filler material, making it ideal for working with thin materials typically found in bike frames, such as aluminum or chromoly steel.

MIG Welder: MIG (Metal Inert Gas) welding is favored for its speed and efficiency, allowing for quick welds without extensive prep work. It uses a continuous wire feed to create the weld, which can be advantageous for beginners who may struggle with the manual feeding required in TIG welding, making it suitable for various frame materials like steel and aluminum.

Stick Welder: Stick welding, or SMAW (Shielded Metal Arc Welding), uses a consumable electrode coated in flux to create the weld and is typically used for thicker materials. While it is less common for bike frames, it can still be effective for repairs or when working with tougher metals; however, the welds can be less aesthetically pleasing and may require more cleanup than TIG or MIG options.

How Do MIG and TIG Welding Techniques Compare for Bike Frames?

| Technique | Welding Process | Best Use Case | Material Compatibility | Heat Input & Distortion | Cost Considerations | Post-welding Cleanup |

|---|---|---|---|---|---|---|

| MIG Welding | Uses a continuous wire feed and gas shield, allowing for faster welding. | Ideal for thin materials and quick projects, suitable for beginners. | Works well with steel, aluminum, and stainless steel. | Higher heat input can lead to distortion in thin materials. | Generally more affordable and accessible equipment. | Minimal cleanup required, but may need grinding in some cases. |

| TIG Welding | Involves a non-consumable tungsten electrode and filler rod, providing more control. | Best for detailed work and thinner materials, preferred by experienced welders. | Best suited for stainless steel and thinner metals. | Lower heat input reduces distortion, ideal for precision work. | Equipment tends to be more expensive and requires more training. | May require more cleanup due to precise finishes. |

Why Is Stick Welding Considered Less Suitable for Bike Frame Construction?

This happens because stick welding, or shielded metal arc welding (SMAW), typically leads to a less refined weld quality and can introduce heat distortion, which is critical in the precision required for bike frame construction.

According to a study by the American Welding Society, stick welding is less suitable for applications requiring high precision and control, such as bicycle frames. Unlike MIG or TIG welding, which allow for better control over the heat input and weld pool, stick welding can produce inconsistent results due to the nature of flux-coated electrodes and the manual handling required.

The underlying mechanism involves the heat input and cooling rates associated with different welding processes. Stick welding often involves higher heat input, which can lead to warping or distortion of the thin-walled tubing commonly used in bike frames. Additionally, the slag produced can obstruct visibility and affect the weld quality, leading to potential weak points that could compromise the structural integrity of the bike. In contrast, MIG and TIG welding provide a cleaner and more controlled environment, allowing for better penetration and less thermal distortion, making them preferable for high-performance applications like bike frames.

What Key Factors Should You Consider When Selecting a Welder for Bike Frames?

When selecting the best welder for bike frames, several key factors should be considered to ensure quality and precision in the welding process.

- Welding Process: Different welding processes are suited for bike frames, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas). TIG welding is often preferred for its ability to produce clean, precise welds, which is crucial for the thin materials typically used in bike frames.

- Material Compatibility: The welder should be compatible with the specific materials used in bike frame construction, such as aluminum, steel, or titanium. Each material requires different welding parameters, so ensuring the welder can handle the intended material is essential for achieving strong joints.

- Power Source: The type of power source (AC or DC) can impact the quality of the weld. DC is generally preferred for welding steel and aluminum, as it provides a more stable arc, while AC is often used for welding aluminum due to its ability to clean the oxide layer on the surface.

- Portability: If you plan to work in different locations or on-site, the welder’s portability is an important factor. A lightweight, compact welder that is easy to transport can enhance convenience and flexibility during the welding process.

- Ease of Use: A welder that is user-friendly with intuitive controls can save time and reduce the learning curve, especially for beginners. Features like adjustable settings, clear displays, and easy-to-navigate menus can enhance the welding experience.

- Duty Cycle: The duty cycle indicates how long a welder can operate continuously before needing to cool down. For bike frame welding, a higher duty cycle is beneficial to allow for extended periods of use without interruptions, which can be crucial during intricate projects.

- Price and Budget: Consider your budget when selecting a welder, as prices can vary significantly. It’s important to balance cost with features and reliability to ensure you invest in a machine that meets your needs without overspending.

- Brand Reputation and Reviews: Researching the brand’s reputation and reading reviews from other users can provide insights into the welder’s performance and reliability. Opting for reputable brands with positive feedback can lead to better overall satisfaction with your purchase.

How Does the Frame Material Influence Your Welder Choice?

The frame material significantly influences the choice of welder for bike frame construction and repairs.

- Steel: Steel frames are common due to their strength and durability. For welding steel, a MIG welder is often preferred, as it provides a good balance of speed and quality, making it easier to handle the thicker materials typically found in steel frames.

- Aluminum: Aluminum frames require specific welding techniques due to their unique properties. TIG welding is usually recommended for aluminum as it allows for greater control and precision, which is essential for achieving strong, clean welds on this lightweight material.

- Carbon Fiber: While carbon fiber is not welded in the traditional sense, understanding its properties can influence the choice of joining methods. Repairing carbon fiber often involves using adhesives or specialized resin systems, rather than welding, which means a welder’s expertise in composite materials is critical.

- Chromoly: Chromoly steel is a popular choice for high-performance bike frames due to its strength-to-weight ratio. When welding chromoly, both MIG and TIG welding can be used, but TIG is often favored for its ability to produce high-quality welds that maintain the material’s integrity and strength.

- Titanium: Titanium frames are lightweight and strong but can be challenging to weld. A TIG welder is ideal for titanium, as it allows for the precise heat control necessary to avoid warping and to ensure a strong bond without compromising the material’s properties.

What Essential Features Should a Quality Bike Frame Welder Possess?

The essential features of a quality bike frame welder include:

- Precision Welding Capability: A good bike frame welder must have the ability to perform precise welds to ensure the structural integrity and aesthetic appeal of the frame. This involves controlling the heat input and maintaining a steady hand to avoid warping or damaging the thin materials commonly used in bike frames.

- Versatility: The best welder for bike frames should be versatile enough to work with different materials such as aluminum, steel, and titanium. This versatility allows the welder to tackle various bike designs and repair tasks effectively, catering to a broader range of cycling enthusiasts.

- Portability: A portable welder is essential for bike frame builders and repairers who may need to work in different locations. Lightweight and compact welders can easily be transported to workshops or events, enabling on-site repairs and fabrication without sacrificing quality.

- Adjustable Settings: High-quality welders come with adjustable settings for voltage, wire feed speed, and heat output. These adjustments allow the welder to customize their approach based on the specific requirements of the metal being worked on, resulting in cleaner and stronger welds.

- Cooling System: An effective cooling system is crucial for maintaining optimal operating temperatures during welding. This feature helps prevent overheating, prolongs the life of the welder, and ensures that the quality of the weld is not compromised due to excessive heat buildup.

- Safety Features: Features such as automatic shut-off, thermal overload protection, and proper insulation are important for ensuring the safety of the welder and the user. These safety measures help to minimize risks associated with welding, such as burns or electrical hazards.

- User-Friendly Interface: A user-friendly interface with clear controls and indicators makes it easier for welders, especially beginners, to operate the machine effectively. This can include digital displays, intuitive knobs, and easy-to-follow instructions, enhancing the overall welding experience.

What Practical Tips Can Help You Achieve Effective Welds on Bike Frames?

To achieve effective welds on bike frames, consider the following practical tips:

- Select the Right Welder: Choosing the best welder for bike frame construction is crucial, with options like TIG and MIG being popular due to their precision and control.

- Prepare Your Materials: Proper preparation of the tubing and joints, including cleaning and fitting, ensures better weld penetration and strength.

- Control Your Heat Settings: Adjusting the heat settings appropriately prevents warping of the thin-walled tubing typical in bike frames.

- Utilize Proper Technique: Employing techniques such as weaving or stringer beads can enhance the quality of the weld and minimize defects.

- Practice on Scrap Metal: Gaining experience through practice on scrap pieces helps in developing skills and understanding the best settings for different materials.

- Use Filler Material Wisely: Selecting the right filler material compatible with your bike frame’s base metal contributes to a strong, ductile joint.

- Inspect Your Work: Regularly checking your welds for defects, such as porosity or undercutting, allows for adjustments before finishing the project.

Choosing the best welder for bike frame construction is crucial, with options like TIG and MIG being popular due to their precision and control. TIG welding provides a clean and strong weld, ideal for thin materials, while MIG welding offers speed and ease, making it suitable for beginners.

Proper preparation of the tubing and joints, including cleaning and fitting, ensures better weld penetration and strength. This preparation phase is vital as contaminants like rust or grease can significantly affect the quality of the weld.

Adjusting the heat settings appropriately prevents warping of the thin-walled tubing typical in bike frames. Maintaining the correct temperature is essential to avoid burn-through, which can compromise the integrity of the frame.

Employing techniques such as weaving or stringer beads can enhance the quality of the weld and minimize defects. These techniques help distribute heat evenly and create stronger joints by ensuring that the weld material fuses properly with the base metal.

Gaining experience through practice on scrap pieces helps in developing skills and understanding the best settings for different materials. This practice allows you to experiment without the pressure of damaging a final product.

Selecting the right filler material compatible with your bike frame’s base metal contributes to a strong, ductile joint. The filler should match the frame material to ensure optimal bonding and avoid issues like brittleness.

Regularly checking your welds for defects, such as porosity or undercutting, allows for adjustments before finishing the project. Early detection of issues can save time and materials, ensuring a more reliable and durable bike frame.

How Can You Ensure a Strong and Durable Weld on a Bike Frame?

To ensure a strong and durable weld on a bike frame, several key factors should be considered:

-

Material Selection: Different materials, such as steel, aluminum, or titanium, require specific welding techniques. For example, TIG welding is often recommended for aluminum due to its precision.

-

Proper Equipment: Choose a welder that suits the material type and thickness. MIG welders are commonly used for bike frames since they offer speed and ease of use, while TIG welders provide greater control for intricate jobs.

-

Clean Surface: Ensure the surfaces to be welded are clean and free of contaminants. Dirt, grease, and rust can weaken the weld. A clean surface promotes better fusion between the metal pieces.

-

Correct Settings: Adjust the welder settings according to the material thickness and type. Factors like voltage, wire speed, and amperage should be optimized for the best results.

-

Welding Technique: Use a steady hand and consistent speed while welding. Maintaining appropriate travel speed and angle can prevent overheating and ensure a uniform heat distribution.

-

Post-Weld Treatment: After welding, techniques such as stress relieving or heat treatment can enhance the strength of the weld, especially in high-stress areas of the frame.

By following these guidelines, the integrity and longevity of the bike frame weld can be significantly improved.

What Safety Precautions Are Critical When Welding a Bike Frame?

When welding a bike frame, several critical safety precautions must be observed to ensure the welder’s safety and the integrity of the frame.

- Protective Gear: Always wear appropriate protective equipment, including a welding helmet with the correct shade, gloves, and flame-resistant clothing.

- Ventilation: Ensure the welding area is well-ventilated to avoid inhaling harmful fumes and gases produced during the welding process.

- Fire Safety: Keep a fire extinguisher nearby and remove any flammable materials from the welding area to prevent fire hazards.

- Electrical Safety: Be aware of electrical safety by using equipment with proper grounding and avoiding wet conditions that could lead to electrical shock.

- Proper Setup: Set up your work area to prevent accidents, ensuring that the bike frame is secured and that you have a clear space to move around while welding.

The importance of protective gear cannot be overstated; it shields against UV radiation, sparks, and hot metal. A welding helmet with an appropriate shade is essential to protect your eyes from the intense light and heat, while gloves and flame-resistant clothing guard against burns and injuries.

Ventilation is crucial because many welding processes emit toxic fumes that can lead to respiratory issues. Working in a confined space without proper airflow can exacerbate these risks, making it vital to weld in open or well-ventilated areas.

Fire safety is another paramount concern, as welding generates sparks that can ignite nearby flammable materials. Keeping a fire extinguisher within reach and clearing the workspace of any combustibles significantly reduces the risk of fire outbreaks.

Electrical safety is important to avoid the risk of shock, especially when using equipment in environments that may be damp or wet. Ensuring that the welding equipment is properly grounded and checking for electrical faults can prevent serious accidents.

Proper setup of the work area is essential to maintain focus and mitigate risks. Securing the bike frame firmly and ensuring ample space for movement helps prevent accidents during the welding process, allowing for a safer and more efficient work environment.

Related Post: