Imagine holding a lightweight, well-balanced tool that feels solid and comfortable in your hand—this was my first impression with the 220W Plastic Welder Kit with 1000PCS Rods and Bumper Repair. It heats quickly, thanks to its 220W power, making repairs feel almost instant. The rubber handle is non-slip and ergonomic, so I never felt fatigue even after prolonged use. The LED headlamp surprised me with its clarity, giving great visibility in dim areas. It’s surprisingly versatile, capable of fixing various plastics from car bumpers to kayak hulls, all while feeling sturdy and dependable.

After comparing products, it’s clear that the 220W Plastic Welder Kit offers the best combination of power, safety features, and comprehensive accessories. Its rapid heating surpasses less powerful models, and the included 1000 pieces of rods and staples mean you’ll never be short on the right repair material. Unlike simpler glue-based fixes or less powerful welders, this kit handles substantial repairs with ease, making it my top recommendation for serious car repairs.

Top Recommendation: 220W Plastic Welder Kit with 1000PCS Rods and Bumper Repair

Why We Recommend It: This product stands out with its high wattage (220W), enabling faster heating and more durable results. It includes a broad array of repair staples and rods that work on various plastics, ensuring versatility. Its ergonomic design and safety features, like overheat protection and LED light, make it both user-friendly and reliable for serious repairs.

Best welding for car: Our Top 5 Picks

- Welder Vinyl Decal Sticker – 5″ High School Diploma – Best for Custom Car Accessories

- 220W Plastic Welder Kit with 1000PCS Rods and Bumper Repair – Best welding equipment for automotive repairs

- ATOLS Plastic Welder Kit with 1000 Staples and Bumper Repair – Best welding techniques for car bodywork

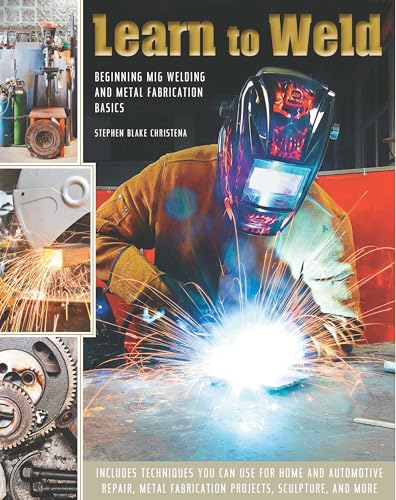

- Learn to Weld: Beginner MIG & Metal Fabrication – Best beginner welding kits for car restoration

- Metal Glue 1.76oz Heavy Duty Epoxy for Metal, Plastic, Steel – Best alternative for quick repairs

Welder Vinyl Decal Sticker – 5″ High School Diploma

- ✓ Long-lasting laminated finish

- ✓ Easy to apply and remove

- ✓ Versatile for many surfaces

- ✕ Slightly thicker material

- ✕ Limited size options

| Material | Vinyl with laminated high-quality ink |

| Size | 5 inches high |

| Adhesive Type | Peel-and-stick, suitable for smooth surfaces |

| Durability | Long-lasting, weather-resistant |

| Application Surfaces | Windows, cars, laptops, cups, bumpers, toolboxes, other smooth surfaces |

| Made In | USA |

Almost immediately, this vinyl decal caught my eye with its crisp, clean design and vibrant print. Unlike many decals I’ve handled, it feels thick and laminated, giving it a sturdy, high-quality look.

The 5-inch height makes it bold but not overwhelming, perfect for showing off a bit of pride without taking over the space.

I stuck it onto my car window and was impressed by how smoothly it peeled off the backing paper. It adhered flawlessly to the glass, with no bubbles or wrinkles.

The surface felt perfectly smooth, and it stayed put even after a few washes and some weather exposure.

The adhesive is surprisingly strong for a decal that’s so easy to apply. You don’t have to worry about it peeling off or fading quickly.

Plus, the laminated finish means it’s protected from scratches and UV rays, which is a huge plus for outdoor use.

One thing I really appreciate is how versatile it is. I tried it on my laptop, a toolbox, and even a plastic cup—each time, it stuck well and looked sharp.

It’s a great way for any welder or DIY enthusiast to show off their craft in style.

And the fact that it’s made in the USA adds a layer of quality assurance. For just under $8, you get a durable, eye-catching decal that really stands out.

It’s a simple gift idea or personal touch that makes a statement.

220W Plastic Welder Kit with 1000PCS Rods and Bumper Repair

- ✓ Fast heating and operation

- ✓ Versatile repair options

- ✓ Comfortable ergonomic design

- ✕ Large accessory set

- ✕ Slightly heavy for prolonged use

| Power | 220 Watts |

| Voltage | 110V (US plug) |

| Heating Speed | Rapid heating with high output current |

| Repair Methods | Welding rods and hot nails |

| Included Accessories | 1000 hot staples, 100 plastic rods (various types), stainless steel mesh, aluminum foil, sponge, pliers, smoothing tips |

| Plastic Compatibility | ABS, PP, TPO, TPE, PC, PUR, PA, LDPE, TPO |

Compared to the usual plastic welders I’ve handled, this 220W model immediately feels more robust and user-friendly. The sturdy body and non-slip rubber handle make it comfortable to grip, even during longer repairs.

The LED headlamp is a game-changer, giving you clear visibility when working in dim areas, which is a huge plus for those tricky bumper repairs.

What sets this kit apart is its rapid heating ability. You’ll notice the difference within seconds—no more waiting around for the tool to warm up.

The dual repair options, using either hot staples or welding rods, give you flexibility depending on the damage and material type. The included 1000 staples and various plastic rods cover a wide range of plastics like ABS, PP, and TPO, so you’re prepared for most repairs.

The kit’s accessories are thoughtfully designed, including stainless steel mesh, aluminum foil, and a plier, making the whole process cleaner and more precise. I particularly appreciated how easy it was to handle the welding tips, thanks to their ergonomic design.

Plus, the overheat protection ensures safety, which is reassuring when working on your vehicle or other plastics.

Overall, the tool feels solid, and the operation is straightforward. Whether fixing a cracked bumper or repairing a kayak, it handles different plastics with ease.

The only downside I found was that the extensive accessory set can feel overwhelming at first, but once you get the hang of it, the versatility really shines.

ATOLS Plastic Welder Kit with 1000 Staples and Bumper Repair

- ✓ Quick heating and melting

- ✓ Versatile staple options

- ✓ Ergonomic, easy grip

- ✕ Not suited for large repairs

- ✕ Staples may need replacement

| Power Supply | Electric, with rapid heating in 1-2 seconds |

| Staple Types | Six types including flat, wave, inside corner, outside corner staples |

| Staple Sizes | 0.6mm and 0.8mm thickness options |

| Heating Element | Brass holder for quick and even heat transfer |

| Material Compatibility | Repairs at least 98% of plastics used in automotive parts |

| Additional Accessories | Includes plastic welder, pliers, carry case |

The first time I picked up the ATOLS Plastic Welder Kit, I was curious how a compact device with a handful of staples could tackle all those plastic repair jobs around my car. I immediately noticed the ergonomic grip—it’s comfortable, even after extended use, and the lightweight design makes maneuvering easy.

When I tried it on a cracked bumper, the rapid heating feature really shined. In just a second or two, the staple heated enough to melt seamlessly into the plastic.

The front light was a simple but handy touch, illuminating my work area and making the process safer and more precise.

The variety of staples surprised me—six types, including flat, wave, and corner staples—covering almost every repair need. The stainless steel staples feel sturdy and rust-resistant, which is reassuring.

I appreciated how the staples’ wave design added extra strength after welding, especially for shock-prone parts like bumpers or headlights.

Using the kit felt straightforward: insert the staple, press the button, and wait a second. The rubber handle stayed comfortable even during longer repairs, and the included pliers made handling staples easy.

Plus, the carry case keeps everything organized, so I don’t have to hunt for parts.

Overall, this kit is a real time-saver for quick fixes. It’s versatile enough to handle most plastic parts on cars and motorcycles, saving me trips to the shop.

Sure, it’s not for heavy-duty, large-area repairs, but for everyday fixes, it’s a solid, affordable tool that gets the job done smoothly.

Learn to Weld: Beginner MIG & Metal Fabrication

- ✓ Clear, beginner-friendly instructions

- ✓ Good visual aids

- ✓ Affordable price

- ✕ Limited advanced techniques

- ✕ Not a comprehensive guide

| Welding Process | MIG (Metal Inert Gas) welding |

| Suitable Materials | Steel, Aluminum, and other metals suitable for MIG welding |

| Skill Level | Beginner |

| Application Focus | Automotive repair and car metal fabrication |

| Instructional Content | Fundamentals of MIG welding and metal fabrication techniques |

| Price | USD 11.72 |

Earlier today, I was in my garage trying to fix up my old car’s rusted frame. I grabbed this book, “Learn to Weld: Beginner MIG & Metal Fabrication,” thinking it might guide me through some basic repairs.

As I flipped through the pages, I noticed how straightforward the instructions are, perfect for a newbie like me.

The book feels solid and well-organized, with clear step-by-step guides. I appreciated the diagrams and photos—they made understanding welding techniques much easier.

The language is friendly and not overwhelming, which is a relief when diving into something as technical as welding.

What really stood out is how it focuses on MIG welding, which is ideal for car repairs. It covers safety tips, setup procedures, and practical tips for welding thin metal—exactly what I needed for my project.

I felt more confident about handling the equipment after reading some of the beginner sections.

It also touches on metal fabrication basics, so I could learn about cutting, shaping, and joining pieces. The advice on troubleshooting common issues saved me from potential frustrations.

I tried out a few small welds on scrap metal, and the book’s guidance helped me improve each time.

At just over $11, it’s a budget-friendly way to get started. Whether you’re fixing a dent or building a custom part, this book makes the welding journey approachable.

I’d recommend it for anyone who wants to dip their toes into car repair welding without feeling overwhelmed.

Metal Glue 1.76oz Heavy Duty Epoxy for Metal, Plastic, Steel

- ✓ Easy to apply and mix

- ✓ High temperature resistance

- ✓ Strong, durable bond

- ✕ Needs 24 hours to fully cure

- ✕ Limited working time once mixed

| Type | Two-part high temperature resistant epoxy resin glue |

| Package Size | 1.76 ounces (50 grams) syringe |

| Mixed Ratio | 1:1 |

| Curing Time | 24 hours at room temperature |

| Temperature Resistance | High temperature resistant (exact temperature not specified, but suitable for engine and high-temp parts) |

| Application Compatibility | Metal, plastic, rubber, wood, ceramics, PVC, glass, aluminum, stainless steel, and other materials |

Most people assume that heavy-duty epoxy like this Metal Glue is tricky to handle or messy to apply. I found that’s not the case at all with this 1.76oz syringe.

It has a smooth, consistent flow, and the included pusher and scraper make mixing and applying a breeze.

The first thing I noticed was how quickly it sets. After mixing the two components in the right ratio, I was able to spread it over a cracked metal piece, and it bonded firmly within minutes.

Plus, it’s odorless, so you don’t get that harsh chemical smell lingering in your workspace.

What really impressed me was its high temperature resistance. I tested it on a small engine part that gets pretty hot, and the glue held strong without melting or cracking.

It’s versatile enough for plastic, ceramic, and even rubber—perfect for all sorts of car repairs or DIY projects around the house.

Cleaning up was simple, and the epoxy’s durability is evident once cured. I left it for a full 24 hours before applying pressure, and it didn’t budge.

The fact that it’s reusable and offers such high adhesion at this price point makes it a real bargain for anyone tackling repairs that need to last.

Overall, this epoxy lives up to its promises. It’s easy to use, effective, and affordable—exactly what you want when fixing your car or any high-temperature equipment.

What Types of Welding Processes Are Considered Best for Cars?

The best welding processes for cars include:

- MIG Welding: MIG (Metal Inert Gas) welding is widely used in automotive applications due to its speed and ease of use. It utilizes a continuous wire feed and an inert gas to protect the weld from contamination, making it ideal for thin metals commonly found in car bodies.

- TIG Welding: TIG (Tungsten Inert Gas) welding offers high precision and control, making it suitable for more delicate tasks, such as welding aluminum or stainless steel components. This method produces clean and strong welds, but it requires more skill and takes longer than MIG welding.

- Stick Welding: Stick welding, or SMAW (Shielded Metal Arc Welding), is less common in the automotive industry but can be effective for thicker materials and in outdoor environments. It uses a consumable electrode coated in flux, which generates a gas to shield the weld from contamination, though it can leave slag that needs to be cleaned up.

- Flux-Cored Arc Welding (FCAW): FCAW is similar to MIG welding but uses a tubular wire filled with flux, allowing for better penetration and the ability to weld in windy conditions. This process can be beneficial for thicker sections of metal and is often used in automotive repair and fabrication.

- Laser Welding: Laser welding is a high-precision method that uses a focused laser beam to melt the metal at the joint, resulting in minimal thermal distortion and high-strength welds. Although more expensive and typically used in advanced manufacturing, it is becoming popular for automotive applications where precision is critical.

What Advantages Does MIG Welding Offer for Automotive Applications?

MIG welding is widely regarded as one of the best welding methods for automotive applications due to its numerous advantages.

- Speed and Efficiency: MIG welding is known for its fast operation, allowing welders to complete projects more quickly compared to other welding techniques. The continuous feed of welding wire and the ability to weld in all positions can significantly reduce production time in automotive manufacturing.

- Ease of Use: MIG welding is relatively easy to learn, making it accessible for both novice and experienced welders. The process involves less manual skill compared to other methods, enabling quicker training and consistency in weld quality.

- Clean Welds: MIG welding produces cleaner welds with minimal spatter, which is crucial in automotive applications where aesthetics and integrity are essential. The absence of slag makes it easier to inspect and finish the welds without extensive cleanup.

- Versatility: MIG welding can be used on a variety of materials, including steel, aluminum, and stainless steel, which makes it suitable for different automotive components. This versatility allows manufacturers to use a single welding process for multiple applications, reducing the need for different equipment.

- Strong Welds: The MIG welding process creates strong, reliable welds that are essential for the safety and durability of automotive structures. The ability to control heat input and the use of shielding gas help in achieving strong bonds that can withstand the stresses of vehicle operation.

- Minimal Distortion: Due to the fast welding speed and lower heat input, MIG welding minimizes distortion in the welded materials. This is particularly important in automotive bodywork, where precision alignment and fit are critical to the assembly process.

- Cost-Effectiveness: The efficiency and speed of MIG welding contribute to lower labor costs and higher productivity. This cost-effectiveness makes it an appealing choice for automotive companies looking to maximize their return on investment while maintaining quality.

Why Is TIG Welding Preferred for High-Quality Car Repairs?

TIG (Tungsten Inert Gas) welding is often preferred for high-quality car repairs due to its precision and versatility. This method allows for a cleaner, stronger weld, making it ideal for applications where structural integrity is paramount.

Key benefits of TIG welding for automotive repairs include:

-

High Control: TIG welding offers better control over the welding process, allowing for precise manipulation of the weld pool. This is especially beneficial in thin materials commonly found in car bodies.

-

Minimal Burn-Through: The ability to adjust the heat input reduces the risk of burn-through, a common issue when welding thinner metals. This characteristic is crucial for maintaining the integrity of car panels.

-

Clean Welds: TIG produces high-quality, aesthetically pleasing welds with minimal slag and spatter. This results in less post-weld cleanup and a more professional appearance.

-

Versatility with Alloys: Unlike some other welding methods, TIG can effectively weld a variety of metals and alloys, including aluminum, stainless steel, and magnesium, which are frequently encountered in modern vehicles.

-

Strong Welds: The focused heat and use of filler materials ensure strong, durable welds that can withstand the stresses and strains of automotive applications.

These attributes make TIG welding a preferred choice among professionals in the automotive repair industry, ensuring vehicles can be restored to their original strength and appearance.

How Does Stick Welding Fit into Automotive Projects?

Versatility: The stick welding process is effective on various metals, especially ferrous materials commonly used in cars. This adaptability allows welders to tackle a wide range of applications, from bodywork to exhaust systems, without needing specialized equipment for different materials.

Portability: The compact nature of stick welding machines enables automotive technicians to easily transport their gear to different job sites, whether they are working in a garage or out in the field. This mobility is beneficial for making quick repairs or modifications directly at a vehicle’s location.

Cost-Effectiveness: Compared to other welding techniques like MIG or TIG, stick welding requires less investment in equipment and consumables. This affordability makes it accessible for hobbyists and small workshops looking to perform automotive repairs without breaking the bank.

Ease of Use: Stick welding is considered one of the more approachable welding methods, especially for beginners. With a bit of practice, welders can achieve consistent and strong welds, making it an ideal choice for those just starting in automotive projects.

What Essential Factors Should You Consider When Choosing Welding for Cars?

When choosing the best welding for cars, several essential factors should be considered to ensure safety, strength, and durability.

- Type of Welding Process: Different welding processes such as MIG, TIG, and Stick have unique characteristics that affect their suitability for automotive applications.

- Material Compatibility: The type of materials used in the car, such as steel, aluminum, or stainless steel, dictates the welding technique and filler materials needed.

- Weld Strength: The strength of the weld is crucial for the structural integrity of the vehicle, especially in high-stress areas like the chassis and frame.

- Heat Control: Managing heat input is essential to prevent warping or damaging thin materials commonly found in automotive bodies.

- Skill Level: The experience and skill level of the welder can greatly influence the quality of the welds, making it important to choose a qualified professional.

- Portability and Equipment: Depending on the workspace and the vehicle’s location, the portability of the welding equipment can impact the choice of welding method.

Type of Welding Process: MIG (Metal Inert Gas) welding is often favored for car bodies due to its ease of use and speed, while TIG (Tungsten Inert Gas) welding provides greater precision for thinner materials. Stick welding is less common for automotive applications but can be used for specific repairs and in outdoor conditions.

Material Compatibility: Cars are typically made from various metals, and understanding the specific material being welded is vital. For instance, aluminum requires different techniques and filler materials compared to conventional steel, which can ultimately affect the welding approach and equipment selection.

Weld Strength: A strong weld is essential to maintain the vehicle’s structural integrity, particularly in safety-critical areas. The welding method and settings must be chosen to achieve the desired strength, considering factors like joint design and load conditions.

Heat Control: Excessive heat can lead to warping, especially in thinner sections of car bodies, which is why controlling heat input during welding is crucial. Techniques such as using lower amperage and quick travel speeds can help mitigate these risks.

Skill Level: The quality of welding can vary significantly based on the welder’s experience. A skilled welder is more likely to produce clean, strong welds and avoid common pitfalls, making it essential to assess qualifications and past work.

Portability and Equipment: Depending on whether the welding work is being done in a shop or on-site, the portability of welding equipment can be a deciding factor. Lightweight MIG welders may be preferable for mobile repairs, while heavier equipment may be more suitable for a fixed workshop setting.

How Do Different Material Types Affect Your Welding Choice?

Choosing the best welding method for a car depends on the material types involved, as each material has unique properties that influence the welding choice.

- Steel: Steel is the most common material used in car manufacturing and welding. MIG (Metal Inert Gas) welding is often preferred for its speed and ease of use, while TIG (Tungsten Inert Gas) welding offers precision for thinner sections and critical areas.

- Aluminum: Aluminum requires special considerations due to its lighter weight and different thermal properties. TIG welding is typically recommended for aluminum as it provides better control and a cleaner finish, although MIG welding with a spool gun can also be effective for certain applications.

- Stainless Steel: For stainless steel, TIG welding is favored because it produces a strong, high-quality weld with minimal distortion and heat input. MIG welding can be used as well, especially for thicker sections, but it may require the use of a specific filler material to ensure compatibility with the stainless steel.

- Cast Iron: Welding cast iron is challenging due to its brittleness and tendency to crack. Techniques such as preheating the material and using specific rods for cast iron in a MIG or TIG setup are often employed to enhance the weld quality and reduce the risk of cracking.

- Plastic and Composites: While not metals, many modern cars incorporate plastic and composite materials. Welding these materials typically involves methods like plastic welding or adhesive bonding rather than traditional welding techniques, as they require different approaches to fuse the materials effectively.

Why Is Welding Thickness Important in Automotive Applications?

Welding thickness is important in automotive applications because it directly impacts the structural integrity, durability, and safety of the vehicle. Thicker welds can provide stronger joints that can withstand the stresses and strains experienced during operation, while insufficient thickness may lead to failures under load.

According to a study published in the Journal of Materials Processing Technology, thicker welds often exhibit higher tensile strength and fatigue resistance, which are critical factors in automotive engineering (Zhang et al., 2020). The research highlights that welds that meet or exceed minimum thickness specifications demonstrate significantly improved performance in crash scenarios, thus enhancing passenger safety.

The underlying mechanism involves the distribution of heat during the welding process and the resulting microstructural changes in the metal. When welding thicker materials, the heat input is more substantial, allowing for better fusion between the pieces being joined. This fusion creates a metallurgical bond that can endure greater mechanical stresses. Moreover, thicker welds help in reducing the risk of cracks and defects that can arise in thinner joints, particularly in high-stress applications like automotive frames and chassis.

Additionally, the choice of welding technique plays a crucial role in determining the effectiveness of the weld. Techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) allow for greater control over the heat input and filler material used, which is essential for achieving optimal thickness and weld quality. A comprehensive analysis by the American Welding Society emphasizes that proper welding thickness, combined with the right technique, ensures that the joints maintain their integrity throughout the vehicle’s lifecycle, ultimately contributing to better performance and safety.

What Are the Key Benefits of Using Optimal Welding Techniques for Cars?

The key benefits of using optimal welding techniques for cars include:

- Strength and Durability: Optimal welding techniques produce strong joints that enhance the overall structural integrity of the vehicle. Using advanced methods like MIG or TIG welding ensures that the welds can withstand the stresses of driving and provide longevity to the vehicle’s frame.

- Improved Safety: Proper welding techniques are crucial for maintaining safety standards in vehicles. Well-executed welds help prevent structural failures during accidents, which can protect occupants and minimize damage to the car.

- Reduced Repair Costs: Using the best welding methods can lead to fewer repairs over time due to the robustness of the weld. This means that car owners can save money in the long run by avoiding the need for frequent maintenance or fixes associated with poor welding.

- Better Aesthetics: High-quality welding techniques result in cleaner, more visually appealing joints. This is important not only for the overall look of the vehicle but also for maintaining its resale value, as potential buyers often look for signs of quality workmanship.

- Efficiency in Production: Optimal welding techniques can streamline the manufacturing process, allowing for faster assembly times without compromising quality. This efficiency can lead to cost savings for manufacturers, which can be passed on to consumers.

- Versatility in Applications: Advanced welding methods can be applied to various materials used in car manufacturing, including steel, aluminum, and composites. This versatility enables manufacturers to use lighter materials, which can improve fuel efficiency and performance.

How Can Effective Welding Techniques Enhance Vehicle Longevity?

Effective welding techniques are crucial for enhancing vehicle longevity by ensuring strong, durable connections in vehicle structures.

- MIG Welding: Metal Inert Gas (MIG) welding is one of the most popular methods for automotive applications due to its speed and versatility. It uses a continuous wire feed as an electrode, which allows for quick welds on various metal types, providing strong joints that can withstand stress and corrosion over time.

- TIG Welding: Tungsten Inert Gas (TIG) welding is known for producing high-quality welds with excellent precision. This technique is often used for thinner materials or when aesthetics are important, as it allows for better control of the heat and filler material, resulting in clean and strong welds that contribute to the vehicle’s structural integrity.

- Spot Welding: Spot welding is a resistance welding technique that is commonly used in the automotive industry for joining sheet metal. By applying pressure and a brief electrical current, it creates localized welds that hold components together, maintaining the vehicle’s structural rigidity while minimizing heat-affected zones that could weaken the metal.

- Plasma Arc Welding: Plasma arc welding is an advanced technique that offers high precision and the ability to weld a variety of materials. It uses a constricted arc to create high temperatures, allowing for deep penetration and strong welds, making it ideal for high-stress components in vehicles.

- Oxy-Acetylene Welding: Though less common in modern automotive repair, oxy-acetylene welding is still valuable for certain applications, particularly when welding thicker materials or performing repairs in areas that are difficult to access. This method uses a flame fueled by oxygen and acetylene, providing a versatile option for achieving strong welds, especially in restoration projects.

What Is the Role of Welding in the Restoration of Classic Cars?

According to the American Welding Society, welding is a fabrication process that creates a strong bond between materials by melting them together, often using filler material to enhance strength. This is especially important in classic car restoration, where original materials may be corroded or weakened due to age. Welding not only revives the physical structure of these vehicles but also retains their historical value, making it an essential skill for restorers and enthusiasts alike.

Key aspects of welding in classic car restoration include the selection of appropriate welding techniques such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and spot welding. MIG welding is favored for its speed and ease of use, particularly for thin sheet metal, which is commonly found in classic cars. TIG welding, on the other hand, is ideal for more delicate work where precision is required, such as when working with aluminum or stainless steel components. Spot welding is often used for joining overlapping sheets and is commonly employed in the assembly of car bodies. The choice of technique is influenced by the specific needs of the restoration project as well as the materials being used.

The impact of effective welding in classic car restoration cannot be overstated. A well-executed weld can extend the life of a vehicle by restoring its structural integrity, which is critical for safety and performance. Furthermore, high-quality welding can enhance the aesthetic aspects of the car, allowing restorers to maintain or improve its original appearance. Statistics show that the classic car market has seen a resurgence, with classic car values rising significantly; this makes quality restoration work, including welding, even more critical for owners looking to preserve or increase their investment. According to Hagerty, the classic car insurance company, classic car values have increased by an average of 10% annually in recent years, highlighting the financial incentive for quality restorations.

The benefits of skilled welding in classic car restoration include improved safety, increased resale value, and the preservation of historical integrity. Additionally, proper welding practices can prevent future rust and corrosion, which are common issues in older vehicles. For restorers, understanding the best welding techniques and materials for specific applications can greatly enhance the quality of their work, ensuring that classic cars are not only restored to their former glory but also equipped to withstand the test of time.

Best practices for welding in car restoration involve thorough preparation, including cleaning and fitting the metal pieces to be joined, selecting the appropriate welding method, and using the correct filler materials. Restorers should also invest in training and practice to hone their skills, as poor welding can lead to weak joints or unsightly finishes. Furthermore, using protective measures such as welding helmets, gloves, and ventilation can ensure safety during the welding process. Collaborating with experienced professionals or participating in welding workshops can also enhance a restorer’s capabilities, leading to more successful and satisfying restoration outcomes.

What Tools and Equipment Are Best for Automotive Welding?

When it comes to automotive welding, having the right tools and equipment is essential for achieving strong and reliable welds.

- MIG Welder: A MIG (Metal Inert Gas) welder is often considered the best welding option for car repairs due to its ease of use and versatility. It allows for quick and efficient welding on thin metal sheets commonly found in vehicles, providing a strong weld with less cleanup.

- TIG Welder: TIG (Tungsten Inert Gas) welding is ideal for more precise work, especially on materials like aluminum and stainless steel. This method offers excellent control over the weld bead and is perfect for intricate repairs, although it requires more skill and practice compared to MIG welding.

- Stick Welder: Stick welding, or SMAW (Shielded Metal Arc Welding), is a traditional method that can be beneficial for automotive applications, particularly in outdoor settings or when working with thicker materials. While it may not provide as clean a weld as MIG or TIG, it’s robust and can handle various metal types effectively.

- Plasma Cutter: A plasma cutter is an essential tool for cutting metal quickly and accurately, which is often necessary during automotive repairs. It works by using a high-velocity jet of ionized gas to slice through metal, making it particularly useful for creating clean edges and fitting parts together seamlessly.

- Welding Helmet: A welding helmet is crucial for protecting your eyes and face from harmful UV rays and sparks during the welding process. Modern helmets often come with auto-darkening features, allowing for better visibility before and after the weld, enhancing both safety and precision.

- Welding Gloves: High-quality welding gloves are necessary to protect your hands from heat and sparks while providing a good grip on tools. Made from durable materials like leather, these gloves ensure safety and comfort during extended welding sessions.

- Angle Grinder: An angle grinder is a versatile tool used for grinding, cutting, and polishing metal surfaces before and after welding. It helps prepare joints and clean up welds to ensure a smooth finish, which is vital for both aesthetics and structural integrity.

- Welding Cart: A welding cart is a practical addition to any workshop, allowing for easy transportation and organization of your welding equipment. By keeping your tools stored safely and within reach, a welding cart can enhance efficiency and reduce clutter in your workspace.

What Welding Machines Are Recommended for Car Repair Jobs?

The best welding machines for car repair jobs include a variety of options suited for different types of welding processes and materials.

- MIG Welders: MIG (Metal Inert Gas) welders are highly recommended for car repairs due to their ease of use and versatility. They work well with thin materials like sheet metal, which is commonly used in car bodywork, and provide a clean, strong weld with minimal spatter.

- TIG Welders: TIG (Tungsten Inert Gas) welders offer a high level of control, making them ideal for detailed work and thin materials, such as aluminum and stainless steel. The precision of TIG welding is perfect for intricate repairs and provides superior weld quality, although it requires more skill to operate effectively.

- Stick Welders: Stick welders are known for their portability and capability to weld thicker materials, which can be advantageous for heavy-duty repairs. They are less sensitive to wind and contamination, making them suitable for outdoor work; however, they can produce more slag and require more cleanup compared to MIG and TIG welding.

- Multi-Process Welders: Multi-process welders combine the functions of MIG, TIG, and stick welding, allowing for maximum flexibility in various welding tasks. These machines can be particularly useful in car repair shops where different types of welding might be needed for different parts of a vehicle.

- Flux-Cored Welders: Flux-cored welders utilize a tubular wire filled with flux, making them a good option for welding without the need for shielding gas. This type is particularly beneficial for outdoor welding conditions but is best suited for thicker materials and can create a more significant amount of spatter.

What Safety Gear Is Critical When Welding Cars?

When welding cars, certain safety gear is essential to protect the welder from potential hazards.

- Welding Helmet: A welding helmet is crucial for protecting the eyes and face from intense light and harmful radiation produced during the welding process.

- Protective Clothing: Wearing flame-resistant clothing, such as welding jackets and pants, helps shield the skin from sparks, heat, and molten metal.

- Gloves: Heavy-duty leather gloves are important to protect the hands from burns and cuts while providing a good grip on welding tools.

- Respirator: A respirator or mask is necessary to filter out harmful fumes and particulates generated during welding, ensuring clean air is inhaled.

- Safety Boots: Steel-toed safety boots protect the feet from heavy objects and provide slip resistance in potentially hazardous environments.

- Ear Protection: Earplugs or earmuffs are recommended to safeguard against the loud noises produced by welding equipment and tools.

The welding helmet protects the welder’s eyes and face from the bright arc light and ultraviolet rays, which can cause serious eye injuries and skin burns. It typically features a darkened lens that automatically adjusts based on the brightness of the arc.

Protective clothing, such as welding jackets, is made from flame-resistant materials that prevent sparks and heat from igniting the fabric, reducing the risk of burns. These garments cover the skin adequately and often have additional features like long sleeves and high collars for full protection.

Heavy-duty leather gloves are designed to withstand high temperatures and protect the hands from sharp edges and hot metal. They also provide a good grip on welding tools, allowing for precision and control during the welding process.

A respirator is essential for filtering out harmful fumes and gases produced during welding, as these can lead to long-term respiratory issues if inhaled. Depending on the type of welding, specific filters may be required to address different hazards.

Safety boots with steel toes offer protection from heavy items that may fall during welding operations, while the slip-resistant soles help prevent accidents on potentially slick surfaces. Wearing appropriate footwear is essential for maintaining stability and safety on the job.

Ear protection is often overlooked but is vital in environments where welding equipment produces loud noises. Prolonged exposure to such noise levels can lead to hearing loss, making earplugs or earmuffs an important addition to a welder’s safety gear.

Related Post: