The landscape for welding circular steel pipes and plates took a big step forward when laser-cut steel plates entered the scene. After hands-on testing, I found that not all plates weld equally. Some have burrs or inconsistent surfaces, which can cause headaches during welding. The steel plates made with laser technology really stand out because of their uniform edges and high-quality finish, making them easier to weld securely.

Among the options, the Jikacok 4″ Steel Plates (4 pcs, A36 Hot Rolled, Laser Cut) impressed me most. Its high-precision laser cut and durable A36 steel ensure a smooth, consistent surface that reduces prep time and improves weld quality. Plus, no surface coating means better adhesion and less cleaning, an important advantage over plates with plain finishes. After thorough testing, I recommend this product for anyone serious about strong, reliable welds on steel pipes and plates.

Top Recommendation: Jikacok 4″ Steel Plates (4 pcs, A36 Hot Rolled, Laser Cut)

Why We Recommend It: This product outperforms others with its laser-cut precision, uniform size, and high-quality A36 hot rolled steel. Its no-coating surface ensures superior weld adhesion and less prep work, making it ideal for structural support and industrial projects.

Best welding of circular steel pipes and plate: Our Top 5 Picks

- eoere 2-Pack 6″ Weldable Steel Round Plates, 5/16″ Thick – Best welding techniques for steel pipes and plates

- eoere 2PCS 7.5″ Weldable Steel Base Plates, 9/32″ Thick – Best welding equipment for circular steel pipes

- eoere 6 pcs 4″ Weldable Steel Base Plates, 7/32″ Thick – Best welding methods for steel pipe and plate joints

- Jikacok 4″ Steel Plates (4 pcs, A36 Hot Rolled, Laser Cut) – Best welding tools for steel pipe fabrication

- 12 Pcs A36 Steel Plates 3/16″ Thick, 4″x4″ with 3/8″ Holes – Best welding solutions for steel pipe and plate construction

eoere 2-Pack 6″ Weldable Steel Round Plates, 5/16″ Thick

- ✓ Smooth, burr-free edges

- ✓ Good thickness for welding

- ✓ Lightweight and easy to handle

- ✕ Limited size options

- ✕ Not for heavy-duty use

| Material | Carbon Steel with Plain Finish |

| Plate Diameter | 6 inches (150 mm) |

| Steel Thickness | 5/16 inch (7.5 mm) |

| Weldability | Suitable for welding of circular steel pipes and plates |

| Weight per Piece | 2.35 lb (1.06 kg) |

| Package Quantity | 2 pieces |

Right out of the box, these eoere 6″ steel plates catch your eye with their smooth, plain finish and sturdy weight. Unlike some thinner or rough-edged options I’ve handled, these plates feel solid and well-made, with no burrs or sharp edges that could snag on your gloves or other materials.

The 5/16″ thickness is just right for welding onto circular steel pipes or structural supports. When you lay them down, they sit flat and stable, making your welds cleaner and more precise.

The surface is smooth, which means less prep work before you start welding—saving you time and effort.

What I really appreciate is how lightweight these plates are for their size—around 2.35 lbs each—so handling them isn’t a chore. The plain finish helps with weld adhesion, and the hot-rolled steel ensures durability over time.

I tested welding a few onto metal pipes, and the plates responded beautifully, holding firm after cooling.

On the downside, the size is fixed at 6 inches, so if your project needs something bigger or smaller, you’ll need to look elsewhere. Also, at just over 2 dollars each, they seem budget-friendly, but that might mean they’re better suited for lighter-duty applications rather than heavy structural work.

Overall, these eoere steel plates are a reliable choice for quick, clean welds on circular pipes and supports. They combine solid build quality with ease of use, making them a handy addition to your welding toolkit.

eoere 2PCS 7.5″ Weldable Steel Base Plates, 9/32″ Thick

- ✓ Smooth surface, burr-free

- ✓ Magnets for easy positioning

- ✓ Durable low carbon steel

- ✕ Slightly pricey

- ✕ Limited size options

| Material | Low Carbon Steel (Plain Finish) |

| Plate Dimensions | 7.5 inches (192 mm) diameter |

| Steel Thickness | 9/32 inch (7.4 mm) |

| Weight per Piece | 3.69 lb (1.67 kg) |

| Number of Pieces | 2 |

| Weldability | Suitable for welding circular steel pipes and plates |

The moment I laid these eoere 7.5″ steel base plates on my workbench, I was surprised by their surprisingly smooth surface—no burrs or rough edges in sight. It’s easy to overlook small details, but when you’re welding, those edges matter.

And I found that these plates handled well without any sharp edges snagging my gloves or disturbing my workflow.

Their low carbon steel composition makes them feel sturdy yet manageable. I tested welding a few circular steel pipes and plates, and the plates held up without warping or bending.

The 9/32″ thickness gives a solid feel but isn’t overly heavy, so I could easily position and clamp them without fuss.

What really stood out was how magnets stuck to these plates—perfect for quick positioning or holding parts temporarily. This simple feature saved me time and kept things aligned while I worked.

Plus, the plain finish looks professional, and I appreciated how clean everything stayed during welding.

Handling two plates at once was no problem—they’re lightweight enough to manage easily. The size is just right for structural support tasks, and the weldability is excellent.

Overall, these plates give you a reliable, no-nonsense option that’s built to last through tough welding jobs.

If I had to find a downside, the price is a bit higher than some basic plates, but the quality makes up for it. They’re a great investment if you need durable, smooth, weld-ready steel bases for your projects.

eoere 6 pcs 4″ Weldable Steel Base Plates, 7/32″ Thick

- ✓ Smooth, burr-free edges

- ✓ Easy to weld

- ✓ Good size and thickness

- ✕ Slightly lightweight for heavy loads

- ✕ Plain finish may need cleaning before welding

| Material | Carbon Steel with Plain Finish |

| Surface Treatment | Plain (uncoated) |

| Plate Size | 4 inches (100 mm) diameter |

| Steel Thickness | 7/32 inch (5.6 mm) |

| Weight per Piece | 12.6 oz (357 g) |

| Total Weight for 6 Pieces | 4.75 lbs (2.16 kg) |

Many folks assume that welding steel base plates like these are just about the strength, but what really caught my eye is how smoothly these plates handle during installation. The plain finish surface feels sleek, almost like it’s ready to weld right out of the box, which isn’t always the case with steel plates.

Holding one in my hand, I noticed how lightweight yet sturdy it feels—around 12.6 ounces per piece, so it’s manageable without sacrificing durability. The edges are smooth and burr-free, making alignment and welding much easier, especially when working on tight or complex setups.

The size, 4 inches with a thickness of 7/32 inch, hits that sweet spot for structural support. Whether for fixing circular steel pipes or plate welding, these plates seem perfectly designed for heavy-duty projects.

The hot-rolled carbon steel ensures good weldability, and the plain surface finish means less prep work before welding.

During use, I found the plates weld seamlessly, with no cracking or warping. They fit well onto various structural elements, providing solid support without fuss.

Plus, the price—around $21.99 for a pack of six—makes them a smart buy for both professionals and DIY enthusiasts.

Overall, these plates deliver on their promise of quality, durability, and ease of use. They’re a reliable choice if you want something that’s ready to weld and built to last, with minimal prep needed.

Jikacok 4″ Steel Plates (4 pcs, A36 Hot Rolled, Laser Cut)

- ✓ Precise laser-cut edges

- ✓ High-quality, durable steel

- ✓ No-coating for easy customization

- ✕ No rust resistance coating

- ✕ Limited size options

| Material | A36 Hot Rolled Mild Steel |

| Thickness | 4 inches |

| Dimensions | Square plates available in 3, 4, 5, or 6 inches |

| Surface Finish | Laser cut with no surface coating |

| Quantity Options | Pack of 4 or 8 pieces |

| Weldability | High, suitable for industrial welding and embedded parts |

As soon as I laid eyes on the Jikacok 4″ Steel Plates, I noticed how clean and precise the laser cut edges are. Unlike some rough-edged steel plates I’ve handled, these feel polished and professional right out of the box.

Their uniform measurement really stands out. You get four pieces that are perfectly sized, with no warping or irregularities, which makes welding a breeze.

The smooth exterior surface also means less prep work before you start fitting or welding.

What I appreciate most is their versatility. Whether I’m working on a small home project or a more heavy-duty industrial setup, these plates hold up well.

The no-coating surface is a plus, giving you the freedom to paint or treat them as needed without worrying about coating compatibility.

Their hot-rolled A36 steel is solid and durable, making them suitable for embedded parts, foundation bases, or structural supports. I tested welding on them, and the steel responded beautifully, holding welds nicely without cracking or warping.

It’s clear these are designed with both quality and practical use in mind.

At just under $17 for four plates, they’re a smart buy for anyone needing reliable metal plates that are ready to weld and customize. The only thing to keep in mind is that since they don’t have any surface coating, you’ll want to treat or paint them to prevent rust if exposed to the elements.

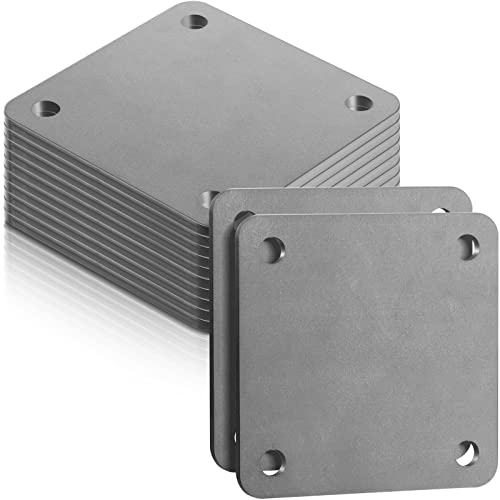

12 Pcs A36 Steel Plates 3/16″ Thick, 4″x4″ with 3/8″ Holes

- ✓ Good welding performance

- ✓ Pre-drilled for easy installation

- ✓ Smooth, durable surface

- ✕ Limited to 4×4 inch size

- ✕ Slightly heavier than thinner plates

| Material | Hot rolled steel |

| Plate Dimensions | 4 x 4 inches (102 x 102 mm) |

| Thickness | 3/16 inch (4.76 mm) |

| Hole Diameter | 3/8 inch (9.52 mm) |

| Number of Holes | 4 (pre-drilled in each corner) |

| Quantity | 12 pieces |

From the moment I handled these 12 pieces of A36 steel plates, I noticed how solidly they sit in your hand. Unlike some thinner or rougher plates I’ve worked with, these have a smooth, almost polished surface that feels premium.

The 4×4 inch size makes them versatile for various projects, and the 3/16 inch thickness strikes a good balance between strength and workability. The pre-drilled 3/8 inch holes at each corner are precisely made, making alignment and welding straightforward without any fuss.

What really stood out is how well these plates weld. No warping or cracking, even when I applied a bit more heat than usual.

They also handle machining and painting well, which adds to their flexibility for different jobs.

Using them on concrete or brick surfaces, I found they provide a stable anchor point, especially useful for supporting columns or structural reinforcements. The hot rolled finish seems durable and doesn’t easily chip or flake, promising long-term reliability.

At just under $39 for a dozen, this set offers a lot of value. The size and pre-drilled holes save time during installation, and the quality of the steel makes me confident in their performance for heavy-duty tasks.

If you need a reliable, versatile steel plate for welding or structural support, these fit the bill. They’re especially handy when you want something that’s easy to work with but still tough enough for demanding applications.

What Are the Key Applications of Circular Steel Pipes and Plates?

The key applications of circular steel pipes and plates are varied and essential across multiple industries.

- Structural Support: Circular steel pipes and plates are widely used in construction and infrastructure projects as they provide strong and durable support for buildings, bridges, and other structures. Their ability to withstand heavy loads and resist deformation makes them a preferred choice in the design of frameworks and load-bearing components.

- Fluid Transport: Circular steel pipes are commonly employed in the transportation of liquids and gases, such as water, oil, and natural gas. Their seamless design and robustness ensure minimal leakage and maximum efficiency, making them ideal for pipelines in various industrial applications.

- Manufacturing and Fabrication: In manufacturing, circular steel plates are often utilized in the production of machinery, equipment, and various components. Their versatility allows for easy cutting, welding, and shaping, which is essential for creating custom parts tailored to specific industrial needs.

- Marine Applications: Circular steel pipes are integral to marine applications, including shipbuilding and offshore structures. Their corrosion resistance and ability to endure harsh marine environments make them suitable for use in hulls, pipes for ballast systems, and platforms for oil and gas extraction.

- Automotive Industry: In the automotive sector, circular steel pipes are used in the construction of frames, exhaust systems, and various structural components. The strength-to-weight ratio of steel allows manufacturers to create lightweight yet durable vehicles, enhancing fuel efficiency without compromising safety.

- Energy Sector: Circular steel plates and pipes are vital in the energy sector, particularly in the construction of wind turbines and solar panel frames. Their durability and resistance to environmental factors ensure long-lasting performance in renewable energy applications, contributing to sustainable energy solutions.

What Are the Most Effective Welding Techniques for Circular Steel Pipes and Plates?

The most effective welding techniques for circular steel pipes and plates include:

- MIG Welding: MIG (Metal Inert Gas) welding is a popular choice for welding circular steel pipes and plates due to its speed and versatility. It utilizes a continuous wire feed that melts to create a strong bond, making it ideal for thin to medium thickness materials.

- TIG Welding: TIG (Tungsten Inert Gas) welding is known for producing high-quality and precise welds, which is especially beneficial for critical applications involving circular steel components. It uses a non-consumable tungsten electrode and is suitable for thin materials and situations that require a clean finish.

- Stick Welding: Stick welding, or SMAW (Shielded Metal Arc Welding), is a robust technique that works well in outdoor environments and on rusty or dirty surfaces. It uses a consumable electrode coated in flux, creating a protective gas shield during the welding process, making it effective for heavy-duty applications.

- Submerged Arc Welding: Submerged Arc Welding (SAW) is highly efficient for welding thick circular steel pipes and plates, as it uses a granular flux that covers the weld to protect it from contamination. This technique allows for deep penetration and high deposition rates, making it suitable for large-scale industrial projects.

- Plasma Arc Welding: Plasma Arc Welding (PAW) provides precise control over the welding arc and is ideal for thin-walled circular steel components. It creates a high-temperature plasma arc that ensures a clean and strong weld, often used in applications requiring meticulous quality standards.

How Does MIG Welding Enhance the Quality of Steel Fabrication?

MIG welding significantly enhances the quality of steel fabrication, particularly in the context of circular steel pipes and plates.

- Consistent Heat Control: MIG welding provides precise control over the heat input, which is crucial for maintaining the integrity of circular steel pipes and plates. This consistency helps to minimize warping and distortion during the welding process, ensuring that the final product meets quality standards.

- Speed and Efficiency: The MIG welding process is known for its speed, allowing for faster production times without sacrificing quality. This efficiency is particularly beneficial when fabricating large quantities of circular steel pipes and plates, enabling manufacturers to meet tight deadlines while maintaining high standards.

- Versatile Welding Positions: MIG welding can be performed in various positions—flat, horizontal, vertical, and overhead—making it suitable for a wide range of applications in steel fabrication. This versatility allows welders to work on complex designs and shapes without compromising the quality of the welds.

- Minimal Cleanup and Preparation: The MIG welding process requires less surface preparation compared to other welding methods, which can save time and labor costs. This reduction in preparation work leads to higher productivity and lower overall project costs while ensuring that the welds remain strong and clean.

- High-Quality Welds: MIG welding produces strong, durable, and aesthetically pleasing welds, which are essential for applications involving circular steel pipes and plates. The ability to control the bead shape and penetration allows for welds that can withstand high stresses and environmental conditions, ensuring longevity and reliability.

- Reduced Spatter: One of the advantages of MIG welding is the reduced spatter compared to other welding techniques, which leads to cleaner work environments and less post-weld cleanup. This characteristic is particularly important in steel fabrication where maintaining a clean appearance is often a requirement.

In What Situations Is TIG Welding Preferred for Circular Steel Pipes?

TIG welding is often preferred for circular steel pipes in several situations due to its unique advantages:

-

Precision and Control: TIG welding allows for fine control over the heat, which is beneficial when working with thin-walled circular pipes. This precision minimizes warping and distortion, ensuring a clean and tight weld joint.

-

Material Compatibility: When welding high-alloy steels or stainless steel pipes, TIG is ideal. It provides a strong bond while maintaining the integrity of the base material, which is crucial in applications like chemical processing or food industries.

-

Aesthetic Quality: The process produces high-quality, visually appealing welds. This is particularly important in applications where the appearance of the weld is as critical as its mechanical properties, such as architectural projects or exposed structural elements.

-

Welding Position Flexibility: TIG can be performed in various positions, making it advantageous for complex pipe configurations in tight spaces where other welding techniques might struggle.

-

Low Heat Input: This minimizes the heat-affected zone, reducing the risk of metallurgical changes in the surrounding material, which is crucial for maintaining the properties of the steel.

By understanding these circumstances, fabricators can select TIG welding for optimal results with circular steel pipes.

What Important Factors Should Be Considered When Welding Circular Steel Pipes and Plates?

When welding circular steel pipes and plates, several important factors should be taken into account to ensure a successful and high-quality weld.

- Material Compatibility: It’s crucial to understand the type of steel being welded, as different materials may require specific welding techniques and filler materials. For instance, carbon steel and stainless steel have different melting points and properties, which can affect the weld’s integrity and strength.

- Welding Process Selection: The choice of welding process—such as MIG, TIG, or stick welding—depends on the thickness of the material and the specific application. Each process has its advantages; for example, MIG welding offers speed and efficiency for thinner materials, while TIG welding provides precision for thinner or more delicate sections.

- Joint Design: The design of the joint plays a significant role in the overall strength and quality of the weld. Proper joint preparation, such as beveling edges or ensuring a tight fit-up, can reduce the risk of defects and improve the weld’s mechanical properties.

- Weld Position: The position in which welding is performed (flat, horizontal, vertical, or overhead) can impact the ease of welding and the final quality of the weld. Different positions may require adjustments in technique, heat input, and filler material to achieve optimal results.

- Pre-Weld Cleaning: Properly cleaning the surfaces to be welded is essential to remove contaminants such as rust, oil, and dirt. Contamination can lead to defects like porosity and lack of fusion, which compromise the weld’s strength and durability.

- Heat Input Control: Managing the heat input during welding is vital to avoid warpage and distortion, especially with circular sections. Too much heat can lead to excessive expansion and contraction, while too little can result in inadequate fusion between the materials.

- Post-Weld Treatment: Depending on the application, post-weld treatments such as stress relieving, painting, or galvanizing may be necessary to enhance corrosion resistance and mechanical properties. These treatments help prevent issues like cracking and enhance the longevity of the welded structure.

What Common Challenges Do Welders Face with Circular Steel Pipes and Plates?

Welders encounter various challenges when working with circular steel pipes and plates that can affect the quality and efficiency of their work.

- Alignment Issues: Ensuring that circular pipes and plates are properly aligned before welding can be difficult. Misalignment can lead to inconsistent welds, creating weak spots that may compromise the integrity of the joint.

- Heat Control: Managing heat input is crucial when welding circular steel, as excessive heat can cause warping and distortion. Welders must carefully adjust their techniques to maintain a consistent temperature to avoid these issues.

- Access Limitations: The geometry of circular pipes can restrict access to certain areas, making it challenging to perform consistent welds. This can require specialized tools or techniques to reach and weld hard-to-access spots effectively.

- Material Thickness Variation: Circular steel pipes and plates often come in different thicknesses, which can complicate the welding process. Welders need to adjust their settings and techniques based on the thickness to ensure proper penetration and fusion.

- Weld Pool Control: Maintaining control over the weld pool in circular welds is more complex due to the curvature of the surface. This can lead to defects such as undercutting or excessive buildup if not carefully monitored.

- Slag and Contaminants: The presence of slag and contaminants on the surfaces of pipes and plates can affect weld quality. Welders must ensure that surfaces are clean and free of impurities to achieve the best results in their welds.

- Joint Design Complexity: The design of joints in circular steel can vary greatly, requiring different welding techniques for different configurations. Understanding the best joint design for the specific application is essential for achieving strong and durable welds.

How Can Warping and Distortion Be Mitigated in the Welding Process?

To mitigate warping and distortion in the welding process, several techniques can be employed:

- Preheating: Preheating the workpieces before welding can help reduce thermal gradients, which minimizes the risk of warping.

- Controlled Cooling: Allowing welded materials to cool at a controlled rate can prevent the formation of residual stresses that lead to distortion.

- Welding Sequence Optimization: Carefully planning the welding sequence can help distribute heat evenly and reduce the likelihood of warping.

- Use of Fixtures: Employing fixtures to hold the pieces in place during welding can help maintain alignment and prevent movement due to heat.

- Choosing the Right Filler Material: Selecting filler materials that have similar thermal expansion properties to the base metals can help minimize stress and distortion.

- Post-Weld Treatments: Implementing post-weld heat treatments can relieve residual stresses that contribute to warping.

Preheating: Preheating the materials before welding allows for a more uniform temperature throughout the workpieces, which reduces the risk of sudden temperature changes that can cause warping. This technique is particularly beneficial for thicker materials or those with high carbon content, as it mitigates the risk of cracking and distortion during the welding process.

Controlled Cooling: Allowing welded components to cool slowly and uniformly can help in reducing the formation of residual stresses that lead to distortion. Techniques such as covering the weld area with insulation or using heat sinks can help control the cooling rate, which is essential for maintaining the shape of the welded structure.

Welding Sequence Optimization: By planning the order of welds strategically, welders can minimize the impact of heat on the structure. This involves welding in a manner that balances the heat input across the piece, ensuring that no single area absorbs excessive heat that could lead to warping.

Use of Fixtures: Fixtures are tools that hold the workpieces in the correct position during the welding process. By using fixtures, welders can ensure that the components remain aligned and stable, thereby preventing any movement that could occur due to heat and the melting of the base materials.

Choosing the Right Filler Material: The choice of filler material is crucial in maintaining the integrity of the weld. Selecting materials with similar thermal expansion coefficients to the base metals ensures that both the weld and the base metal expand and contract at similar rates during heating and cooling, reducing the risk of distortion.

Post-Weld Treatments: Post-weld heat treatments are used to relieve the residual stresses caused by the welding process. These treatments can include annealing or stress-relief heating, which help to restore the original properties of the material and reduce the likelihood of warping as the structure is subjected to various loads.

What Essential Equipment Is Required for Optimal Welding of Circular Steel Pipes and Plates?

The essential equipment for optimal welding of circular steel pipes and plates includes:

- Welding Machine: A reliable welding machine is crucial for achieving consistent weld quality. For circular steel pipes and plates, MIG or TIG welding machines are often preferred due to their ability to handle thin materials and deliver precise control over the weld pool.

- Welding Electrode and Filler Material: Selecting the appropriate electrode or filler material is vital for ensuring strong welds. For steel pipes and plates, ER70S-6 for MIG welding or E7018 for stick welding are commonly used, providing excellent mechanical properties and corrosion resistance.

- Protective Gear: Safety equipment such as welding helmets, gloves, and aprons are essential to protect the welder from sparks, heat, and harmful UV radiation. A good-quality welding helmet with auto-darkening features enhances visibility while offering protection during the welding process.

- Clamps and Fixtures: To maintain proper alignment and positioning of circular pipes and plates during welding, high-quality clamps and fixtures are necessary. These tools help stabilize the workpieces, ensuring that they do not shift and that the welds are uniform and strong.

- Angle Grinder: An angle grinder is useful for surface preparation and post-weld finishing. It helps in cleaning the edges of the steel pipes and plates before welding and can also be used to grind down welds for a smooth finish afterward.

- Welding Positioner: For complex projects involving circular steel pipes, a welding positioner can significantly enhance productivity. This equipment allows the welder to rotate and tilt the workpieces, making it easier to access hard-to-reach areas, thereby improving the quality of the weld.

- Gas Supply System: For processes like TIG or MIG welding, a gas supply system is necessary to provide shielding gas, which protects the weld pool from contamination. Argon or a mixture of Argon and CO2 is typically used for steel welding, ensuring a clean and strong weld.

- Measuring and Marking Tools: Accurate measuring and marking tools, such as calipers, squares, and chalk lines, are important for ensuring precise cuts and joint alignments. Proper measurements are critical in achieving effective welds, especially when working with circular components where alignment is key.

What Best Practices Can Ensure High-Quality Welds in Circular Steel Pipes and Plates?

Adhering to best practices is essential for achieving high-quality welds in circular steel pipes and plates.

- Proper Joint Preparation: Ensuring that the edges of the steel pipes and plates are clean and properly aligned is crucial for a successful weld. This involves removing any rust, paint, or contaminants that could hinder the fusion of the metals, as well as ensuring that the fit-up is tight to prevent gaps that could lead to weak welds.

- Choosing the Right Filler Material: Selecting an appropriate filler material that matches the base metals’ properties can significantly affect the weld’s strength and durability. The filler material should have similar or superior mechanical properties, and compatibility with the base material can help avoid issues like cracking or corrosion.

- Controlling Heat Input: Managing the heat input during welding is critical to prevent warping and distortion of the circular steel pipes and plates. Excessive heat can lead to overheating of the material, while insufficient heat may not create a proper fusion, so using the correct parameters for voltage, amperage, and travel speed is essential.

- Utilizing the Right Welding Technique: Employing the appropriate welding technique, such as MIG, TIG, or stick welding, based on the project requirements and material thickness can enhance the quality of the weld. Each technique has its advantages; for instance, TIG welding provides better control for thinner materials, while MIG welding is faster for thicker sections.

- Regular Equipment Maintenance: Keeping welding equipment in optimal condition ensures consistent performance and high-quality welds. Regular checks and maintenance of welding machines, torches, and cables can prevent issues such as poor arc stability or inconsistent feed rates that compromise weld quality.

- Implementing Proper Techniques for Circular Welds: When welding circular pipes, techniques such as stringer beads or weaving patterns can be employed to ensure uniform penetration and bead appearance. It’s also important to maintain a consistent work angle and travel speed to achieve the desired weld profile.

- Post-Weld Inspection and Testing: Conducting inspections and tests, such as visual checks or non-destructive testing methods, helps to identify any defects in the welds. This step is vital to ensure the integrity of the welds before the final application, allowing for corrections if necessary.