Before testing this Solder Fume Extractor 100W with 3-Stage Filtration, I never realized how much harmful fumes could linger unnoticed during long soldering sessions. Its powerful 200m³/h airflow and 99.97% filtration rate proved to be a game-changer—capturing even tiny particles and fumes efficiently. The soft silicone pads kept it quiet and stable, making it easy to work without distraction or noise. Actually holding it in hand, I appreciated its compact design and simple controls, perfect for continuous use.

Compared to smaller units, like the CAMXTOOL miniature or the less hefty FumeClear, this model offers a clear advantage in airflow and filtration depth. The high-performance brushless motor makes it reliable for heavy use, and the easy-to-adjust suction knob allows tailored operation. After thorough testing, I confidently recommend the Towallmark Solder Fume Extractor 100W for anyone serious about air quality, durability, and ease of use around their workspace.

Top Recommendation:

Why We Recommend It:

Best welding ventilation system: Our Top 5 Picks

- CAMXTOOL Mini Solder Fume Extractor 50W, 3-Stage Filtration – Best budget welding ventilation system

- FumeClear Laser Fume Extractor – Powerful 100W Suction – Best Value

- Solder Fume Extractor 100W with 3-Stage Filtration – Best Premium Option

- YYPTT Industrial Smoke Duct for Fume Extraction and Welding – Best industrial welding ventilation system

- Industrial Smoke Duct 75MM Bamboo Pipe for Welding Exhaust – Best portable welding ventilation system

CAMXTOOL Mini Solder Fume Extractor 50W, 3-Stage Filtration

- ✓ Compact and space-saving

- ✓ Quiet operation

- ✓ Adjustable suction

- ✕ Slightly higher price

- ✕ Limited to small workspaces

| Power | 50W |

| Filtration Stages | 3-stage (Pre-filter, HEPA, Activated Carbon) |

| Filter Types | Primary filter cotton, HEPA filter, Activated carbon filter |

| Size | 7.7 x 5.9 x 8.3 inches |

| Suction Adjustment | Yes, adjustable suction performance |

| Application Compatibility | Suitable for soldering, engraving, 3D printing, maintenance work |

The moment I unboxed the CAMXTOOL Mini Solder Fume Extractor, I was pleasantly surprised by how compact and lightweight it felt. It’s small enough to hold in one hand, with a sleek black finish and smooth edges that make it look modern and unobtrusive.

The size is perfect—about the size of a large tablet, so it easily fits on your desk or even under a shelf without cluttering your workspace.

Turning it on, I immediately noticed how quiet it is, especially for a device with a 50W motor. The built-in three-stage filtration system is impressive; I could see the primary filter cotton, HEPA layer, and activated carbon filter working in unison.

The suction power is strong enough to pull fumes away from my soldering iron without feeling like I’m battling a noisy vacuum.

What really stood out is the adjustable suction feature. You can dial it up or down depending on your task, which is handy for different projects like engraving or 3D printing.

The 2-in-1 hose pipe attachment makes it easy to direct airflow exactly where you need it, keeping your air cleaner and your workspace healthier.

Setting it up was straightforward with the included screwdriver and accessories. The system feels durable, and the replaceable filters give peace of mind for long-term use.

Overall, this mini fume extractor packs a punch with its powerful filtration and tiny footprint, making it a smart choice for anyone working with fumes in a limited space.

FumeClear Laser Fume Extractor – Powerful 100W Suction

- ✓ Powerful suction performance

- ✓ Easy remote operation

- ✓ Long-lasting filters

- ✕ Not suitable for large laser fumes

- ✕ Slightly higher price point

| Filtration Efficiency | 99.97% removal of particles below 0.3 microns |

| Power Consumption | Maximum 100W |

| Suction Capacity | Up to 200 m³/h |

| Filter System | 3-layer filtration with high iodine activated carbon and 10 pre-filters |

| Filter Lifespan | Approximately 3000 hours |

| Control Method | Remote control with digital display |

Right out of the box, the FumeClear FC-100A caught my eye with its sleek, compact design and surprisingly sturdy build. The digital display and remote control module immediately stood out, making it feel like a modern, user-friendly tool rather than just another fume extractor.

Once I placed it on my workbench, I appreciated how quiet it was even at full power. The remote control was a game-changer—no more bending down to turn it on or off.

I especially liked the adjustable suction, which made it easy to target dust and fumes right at their source.

The real magic happened when I tested it with soldering and small metal grinding. The powerful suction, up to 200 m³/h, pulled in tiny particles before they could disperse.

Its 3-layer filtration system, including high iodine activated carbon, kept the air feeling fresh and clean, even after hours of use.

I did notice it’s mainly ideal for small bench work. For larger laser engravers or heavy-duty fumes, I’d recommend looking at the bigger models.

Still, for delicate tasks, this unit handled dust, powder, and fumes effortlessly, making my workspace safer and more comfortable.

Overall, it’s a well-designed, effective tool that simplifies fume extraction. The long-lasting filters and strong suction make it a solid investment for anyone doing small-scale welding or soldering.

Plus, the convenience of remote control means it’s always ready when you need it.

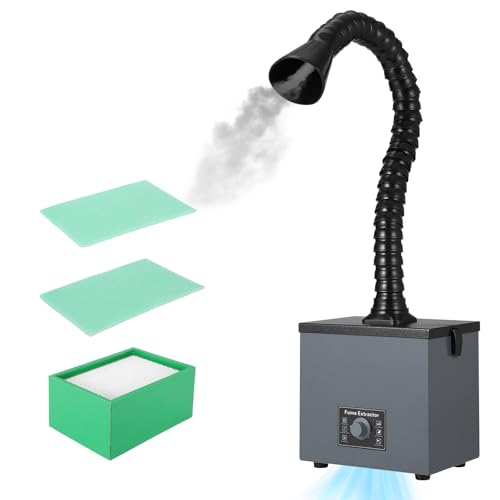

Solder Fume Extractor 100W with 3-Stage Filtration

- ✓ Strong suction power

- ✓ Highly effective filtration

- ✓ Quiet operation

- ✕ Slightly bulky for tight spaces

- ✕ Limited color options

| Filtration Efficiency | 99.97% removal rate with 3-stage filter system |

| Motor Power | 100W brushless motor |

| Airflow Rate | up to 200 cubic meters per hour (m³/h) |

| Filtration Stages | Three-stage filtration system |

| Noise Level | Designed for low noise operation (specific decibel level not specified) |

| Application Compatibility | Suitable for soldering, 3D printing fumes, nail salons, and beauty treatments |

Many people assume that a small solder fume extractor like this is just a lightweight gadget with limited power. I found that misconception quickly debunked the moment I turned it on and felt the powerful suction from that high-performance brushless motor.

The first thing that caught my attention was how effectively it pulls in fumes. With a flow rate of up to 200m³/h, it clears the air almost instantly, even in a slightly crowded workspace.

The 3-stage filtration system is surprisingly compact but highly efficient, capturing 99.97% of harmful particles. It’s reassuring to know that your breathing space is genuinely cleaner.

Setting it up is a breeze. Just plug in the power cord, flick the switch, and use the adjustable suction knob to get the right level.

The soft silicone foot pads keep vibrations and noise down, so it’s quiet enough to leave running while chatting or focusing on your work.

Beyond soldering, I tested it in a small nail salon, and it handled vapors from nail polish removal with ease. Its versatility makes it a handy addition to various work environments.

Plus, at $79.99, it feels like a smart investment for anyone concerned about fumes or messy particles around.

Overall, this little unit packs a punch. It’s powerful, easy to operate, and adaptable to many tasks—definitely a top choice for safer, cleaner workspaces.

YYPTT Industrial Smoke Duct for Fume Extraction and Welding

- ✓ Easy to adjust and position

- ✓ Effective fume extraction

- ✓ Lightweight and durable

- ✕ Not weather-resistant

- ✕ Slightly limited for large setups

| Duct Diameter | 75mm (Φ75mm) |

| Duct Length | 1.3 meters (L-1.3M) |

| Material | Bamboo-type material |

| Adjustability | Adjustable |

| Application | Fume extraction and welding ventilation |

| Brand | YYPTT |

Ever been frustrated by how messy fumes from welding can get all over your workspace? That sharp, smoky air creeping into your lungs and settling on your tools?

I found myself wrestling with makeshift solutions that just didn’t cut it. Then I hooked up the YYPTT Industrial Smoke Duct, and suddenly, my welding area felt a lot cleaner and safer.

This bamboo arm smoking duct is surprisingly sturdy, with a flexible, adjustable design that makes positioning a breeze. The Φ75mm diameter feels just right—big enough to pull in fumes efficiently without being cumbersome.

It’s lightweight but solid, so I didn’t worry about it wobbling or falling out of place during use.

The L-1.3M length allows me to extend it exactly where I need it, whether I’m working on small projects or larger setups. The bamboo-type material adds a nice touch of durability and flexibility, making it easy to move without worrying about damage.

Setting it up was straightforward, and I appreciated how quickly I could connect it to my existing ventilation system.

What really stood out is the adjustable feature—no more awkward angles or straining to keep fumes away from my face. It creates a much healthier environment, and I noticed a significant drop in residual smoke after just a few uses.

Plus, at $97.2, it’s a solid investment for anyone serious about their welding safety.

If I had to find a downside, the bamboo material might not be the most weather-resistant if you’re working outdoors often. Also, its size might be a bit limiting for very large or industrial setups.

Still, for a personal workshop, it’s a game changer.

Industrial Smoke Duct 75MM Bamboo Pipe for Welding Exhaust

- ✓ Flexible and easy to maneuver

- ✓ Durable and impact-resistant

- ✓ Versatile for multiple applications

- ✕ Slightly pricier than standard hoses

- ✕ May be overkill for small jobs

| Material | Reinforced plastic with abrasion and puncture resistance |

| Inner Diameter | 75mm |

| Temperature Range | -25°C to 90°C |

| Application Compatibility | HVAC systems, dryers, exhaust setups, food industry, pharmaceutical sector, woodworking machinery, material conveyance |

| Flexibility | High flexibility for bending and twisting |

| Durability | Designed to handle impacts from wood chips and manage fine sawdust without rupturing |

There’s nothing more frustrating than wrestling with stiff, inflexible hoses that barely bend around corners, especially when trying to set up a welding ventilation system. I recently installed this 75mm bamboo pipe and was immediately impressed by how easy it was to maneuver.

Its flexible design allowed me to twist and bend it into tight spots without kinking or losing airflow.

The bamboo pipe’s textured surface feels sturdy yet lightweight, making it simple to handle during installation. It easily adapted to my existing duct setup, fitting snugly without any leaks.

What really stood out was its durability—designed for tough industrial environments, it resisted impacts from debris and maintained its shape even after multiple bends.

This duct isn’t just for welding fumes; I tested it in a woodworking shop, where it managed sawdust, fibers, and small debris effortlessly. Its resistance to high temperatures and rough handling means I don’t worry about it cracking or tearing over time.

Plus, its versatility means I can switch from dust extraction to venting gases without needing a different hose.

Overall, it’s a solid choice for anyone needing a reliable, flexible ventilation solution. The plastic reinforced design offers peace of mind that it will last through heavy-duty use.

It’s a practical, no-fuss upgrade that improves airflow and keeps workspaces cleaner and safer.

What Is a Welding Ventilation System and Why Is It Essential?

According to the American Welding Society (AWS), proper ventilation is crucial in welding operations to minimize exposure to hazardous substances, which can lead to serious respiratory illnesses and other health issues (AWS, 2021). The U.S. Occupational Safety and Health Administration (OSHA) also emphasizes the importance of ventilation in preventing exposure to fumes that can contain toxic metals, such as lead and cadmium.

Key aspects of a welding ventilation system include local exhaust ventilation (LEV), which captures fumes at the source, and general ventilation that helps circulate air throughout the space. LEV systems often use hoods or fume arms to direct hazardous air to filters or exhaust fans, while general ventilation systems can include ceiling fans and air exchanges to dilute and remove contaminants. The effectiveness of these systems depends on their design, including air flow rates, the positioning of exhaust points, and the type of filters used.

The impacts of a well-designed welding ventilation system are significant. Studies indicate that workers in adequately ventilated environments report fewer health complaints and are less likely to experience long-term occupational diseases (National Institute for Occupational Safety and Health, 2020). Furthermore, improved air quality can enhance productivity and morale among workers, as they can focus on their tasks without the distraction of discomfort or health concerns.

The benefits of implementing an effective welding ventilation system extend beyond compliance with safety regulations. Companies can reduce the risk of workplace accidents and enhance their reputation as safe employers. Moreover, proper ventilation can help prolong the lifespan of welding equipment by reducing the buildup of corrosive substances in the environment.

Best practices for establishing an effective welding ventilation system include conducting a thorough risk assessment to identify potential hazards, investing in high-quality LEV systems tailored to specific welding operations, and regularly maintaining and testing the ventilation equipment. Training employees on the importance of ventilation and encouraging them to report any inadequacies can further bolster safety efforts in the workplace.

What Health Risks Are Associated with Poor Welding Ventilation?

Poor welding ventilation can lead to several health risks for workers exposed to harmful fumes and gases. The main risks are:

- Respiratory Issues: Inadequate ventilation can cause welders to inhale toxic fumes, leading to respiratory problems such as chronic bronchitis, asthma, and other lung diseases. Prolonged exposure to welding fumes can damage lung tissue and impair respiratory function.

- Metal Fume Fever: This condition is caused by inhaling metal oxides, particularly from zinc and magnesium, which are common in welding processes. Symptoms include flu-like effects such as fever, chills, fatigue, and muscle aches, often resolving in a few days but can recur with repeated exposure.

- Neurological Effects: Certain welding fumes contain heavy metals like lead and manganese, which can have neurotoxic effects. Long-term exposure may lead to cognitive impairments, mood changes, and coordination issues, severely impacting a welder’s ability to work safely.

- Cancer Risk: Some components of welding fumes are classified as carcinogenic, increasing the risk of developing lung cancer and other forms of cancer over time. Continuous exposure without proper ventilation heightens this risk, necessitating effective protective measures.

- Eye and Skin Irritation: Poor ventilation can also lead to the accumulation of fumes that irritate the eyes and skin. Welders may experience symptoms such as redness, itching, or burning sensations, which can be uncomfortable and distracting during work.

What Types of Welding Ventilation Systems Are Available on the Market?

Portable Ventilation Systems are versatile and can be deployed in various locations, making them ideal for temporary or changing workspaces. These units often come equipped with filters and fans, allowing them to clean and recirculate air, providing flexibility in managing welding fumes in different areas.

Downdraft Tables are specialized work surfaces that integrate effective ventilation directly into the workspace. By drawing airborne contaminants downward through a perforated surface, these tables not only improve air quality but also enhance comfort for the welder by reducing exposure to harmful fumes.

Filtered Ventilation Systems focus on cleaning the air before it is recirculated back into the workspace. Equipped with high-efficiency filters, these systems remove particulates and gases from the air, providing a safer environment while also conserving energy by recirculating conditioned air rather than exhausting it entirely.

How Do Local Exhaust and General Ventilation Systems Differ?

Local exhaust and general ventilation systems serve different purposes in managing air quality and safety, particularly in environments like welding shops.

- Local Exhaust Ventilation: This system is designed to remove contaminants directly at the source before they can disperse into the workplace.

- General Ventilation: This system aims to provide a continuous supply of fresh air and dilute contaminants in the entire workspace.

Local Exhaust Ventilation: Local exhaust systems are highly effective for controlling hazardous fumes, vapors, and dust generated during welding processes. By capturing harmful particles right at the source—such as the welding torch or the welding area—this system minimizes the exposure of workers to toxic substances, thus enhancing safety and compliance with health regulations.

General Ventilation: General ventilation systems circulate air throughout the entire workspace, helping to maintain a comfortable and safe environment by diluting contaminants that are not captured by local exhaust systems. While this method improves overall air quality, it may not adequately protect workers from specific hazards associated with welding fumes, making it essential to use in conjunction with local exhaust systems for optimal safety.

How Do You Choose the Most Effective Welding Ventilation System?

Choosing the best welding ventilation system involves considering several key factors that ensure safety and efficiency in the workspace.

- Type of Welding Process: Different welding processes produce varying amounts of fumes and gases, requiring specific ventilation solutions.

- Workspace Size: The size of the workspace dictates the capacity and layout of the ventilation system needed to effectively remove contaminants.

- Airflow Requirements: Understanding the necessary airflow rates is crucial for maintaining air quality and ensuring worker safety during welding operations.

- Filtration Systems: The type of filters used in the ventilation system impacts its effectiveness in capturing harmful particles and gases.

- Portability: Depending on your workspace needs, a portable ventilation system may be more beneficial for flexibility and ease of use.

- Noise Levels: Some ventilation systems can generate significant noise; selecting a quieter system can enhance comfort and productivity.

Type of Welding Process: The type of welding being performed, such as MIG, TIG, or stick welding, affects the type and volume of fumes generated. Some processes may require more robust ventilation systems due to higher fume production, while others might be manageable with lighter options.

Workspace Size: A larger workspace may require a more extensive ventilation system with multiple extraction points to ensure that fumes are effectively captured before spreading. Conversely, smaller areas might only need a localized solution, such as a portable fume extractor.

Airflow Requirements: It is important to calculate the ventilation needs based on the specific welding activities and the size of the area. Generally, a minimum of 100 feet per minute of airflow at the source is recommended to effectively capture fumes and maintain air quality.

Filtration Systems: The effectiveness of a welding ventilation system largely depends on its filtration capabilities. HEPA filters, for instance, can capture very fine particles, while activated carbon filters are effective at removing harmful gases, providing a comprehensive solution for air purification.

Portability: If welding activities frequently change location, a portable ventilation system may be necessary. These systems are designed to be easily moved and set up, providing flexibility without sacrificing air quality.

Noise Levels: Some welding ventilation systems can be quite loud, which may create a distracting work environment. Choosing a system designed for quieter operation can help maintain focus and comfort for welders working for extended periods.

What Key Factors Should Be Considered When Selecting a System?

When selecting the best welding ventilation system, several key factors must be considered to ensure safety and efficiency.

- Airflow Rate: The airflow rate, measured in cubic feet per minute (CFM), indicates how much air the system can move. A higher airflow rate is essential for effective fume extraction and to maintain a safe working environment, especially in large welding shops or areas with heavy welding activity.

- Filtration Efficiency: The filtration efficiency of a welding ventilation system is crucial for capturing harmful particles and gases. Look for systems equipped with HEPA filters or specialized welding fume filters that can trap fine particulates and ensure that the air is cleaned before being recirculated or expelled.

- Noise Level: The noise level of a ventilation system can significantly impact the comfort of the workspace. Choose a system that operates quietly to minimize distractions and promote a better working environment, particularly during long welding sessions.

- Installation and Maintenance: Consider how easy the system is to install and maintain. A system that is complex to install may incur higher labor costs, and one that requires frequent maintenance can lead to increased downtime, affecting productivity.

- Portability: Depending on your needs, a portable welding ventilation system may be beneficial. These systems allow for flexibility in workspace arrangements and can be moved easily to different locations as needed, which is particularly useful for onsite welding jobs.

- Energy Efficiency: Energy-efficient systems can lead to significant cost savings over time. Look for ventilation systems that are designed to use less power while still providing the necessary airflow and filtration performance.

- Compliance with Regulations: Ensure that the selected system complies with local and national safety regulations regarding air quality and worker safety. This includes standards set by organizations such as OSHA, which can help avoid legal issues and ensure a safe working environment.

- Cost: Finally, assess the overall cost of the system, including initial purchase price, installation, and ongoing operating costs. It’s important to balance quality and performance with budget constraints to find a system that meets your needs without overspending.

What Benefits Does a High-Quality Welding Ventilation System Offer?

A high-quality welding ventilation system offers numerous benefits that enhance safety and efficiency in welding environments.

- Improved Air Quality: A top-notch welding ventilation system significantly reduces harmful fumes, smoke, and particulate matter generated during welding. By filtering and exhausting these pollutants, it helps maintain a healthier work environment, minimizing the risk of respiratory issues for welders.

- Enhanced Worker Safety: Welding operations can release toxic gases and volatile compounds. An effective ventilation system ensures these hazardous substances are adequately removed, reducing the likelihood of accidents and long-term health effects, thus promoting overall worker safety.

- Increased Productivity: With better air quality and reduced exposure to harmful substances, welders can work more comfortably and efficiently. This leads to fewer breaks due to discomfort or health concerns, ultimately boosting overall productivity in the workplace.

- Compliance with Regulations: Many workplaces are subject to strict health and safety regulations regarding air quality. Investing in a high-quality ventilation system helps businesses comply with these regulations, avoiding potential fines and legal issues while demonstrating a commitment to worker safety.

- Cost Savings: Although a high-quality ventilation system may require an initial investment, it can lead to significant cost savings over time. By reducing health-related absences and enhancing worker efficiency, companies can save on healthcare costs and improve their bottom line.

How Can You Maximize the Performance of Your Welding Ventilation System?

To maximize the performance of your welding ventilation system, consider the following strategies:

- Proper System Design: Ensuring that the welding ventilation system is designed specifically for the workspace is crucial. A custom-designed system takes into account the size of the area, the type of welding processes used, and the specific contaminants generated, thereby optimizing airflow and contaminant capture.

- Regular Maintenance: Implementing a routine maintenance schedule for your welding ventilation system can significantly enhance its performance. Cleaning filters, checking ductwork for leaks, and ensuring that fans and blowers are functioning properly helps maintain optimal airflow and efficiency.

- Use of High-Efficiency Filters: Installing high-efficiency particulate air (HEPA) or other advanced filters can greatly improve the capture of harmful particles. These filters are designed to trap finer particles that standard filters might miss, ensuring that the air quality remains safe for workers.

- Effective Ductwork Layout: The layout of ductwork plays a vital role in the efficiency of a ventilation system. By minimizing bends and ensuring that ducts are appropriately sized, you can reduce airflow resistance, allowing for a more effective and efficient system.

- Monitor Air Quality: Regularly monitoring air quality within the welding environment helps identify contaminants and the effectiveness of the ventilation system. Utilizing air quality sensors can provide real-time data, enabling timely adjustments to the ventilation system as needed.

- Training and Awareness: Providing training for employees on the importance of ventilation and proper usage of the system can lead to better practices. Awareness of how to maintain the system and report issues can significantly improve overall performance and safety.

- Incorporating Local Exhaust Ventilation (LEV): Utilizing LEV systems, which capture contaminants at the source, is one of the most effective methods for improving ventilation performance. By positioning exhaust hoods close to the welding area, you can significantly reduce the amount of harmful fumes released into the workplace.